High-stability silver oxide-graphene composite material as well as preparation method and application thereof

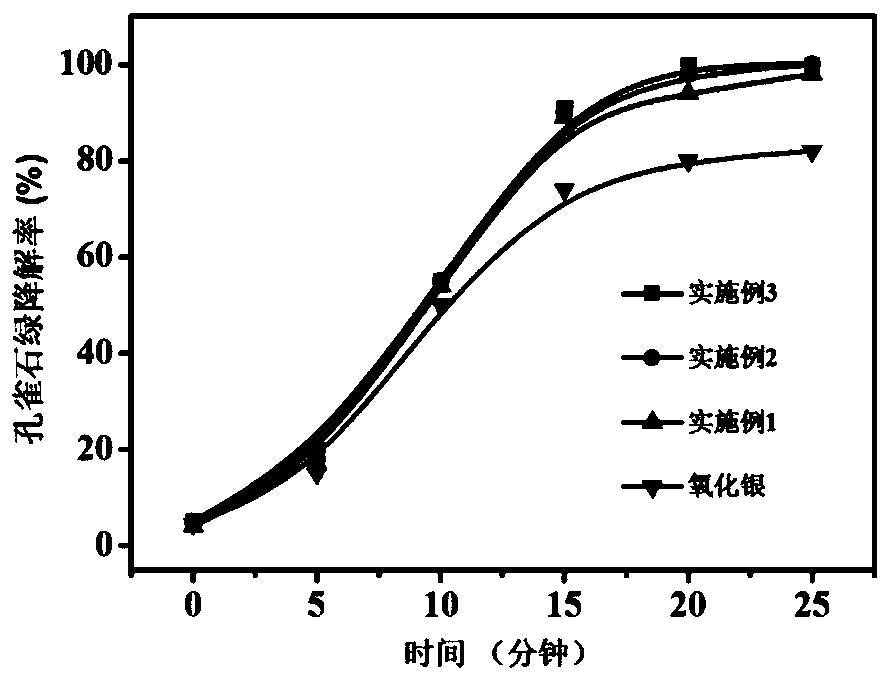

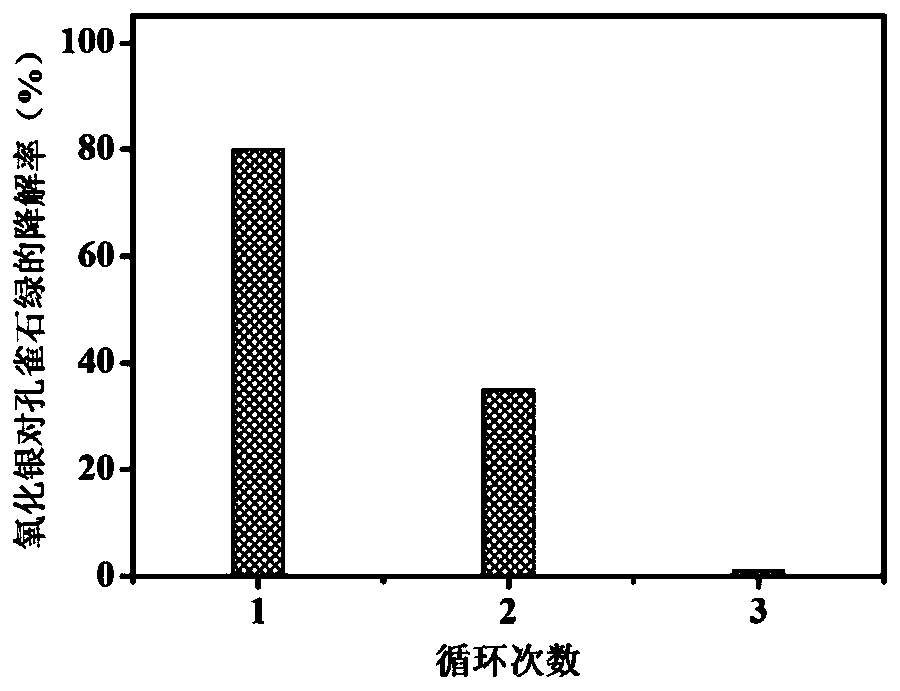

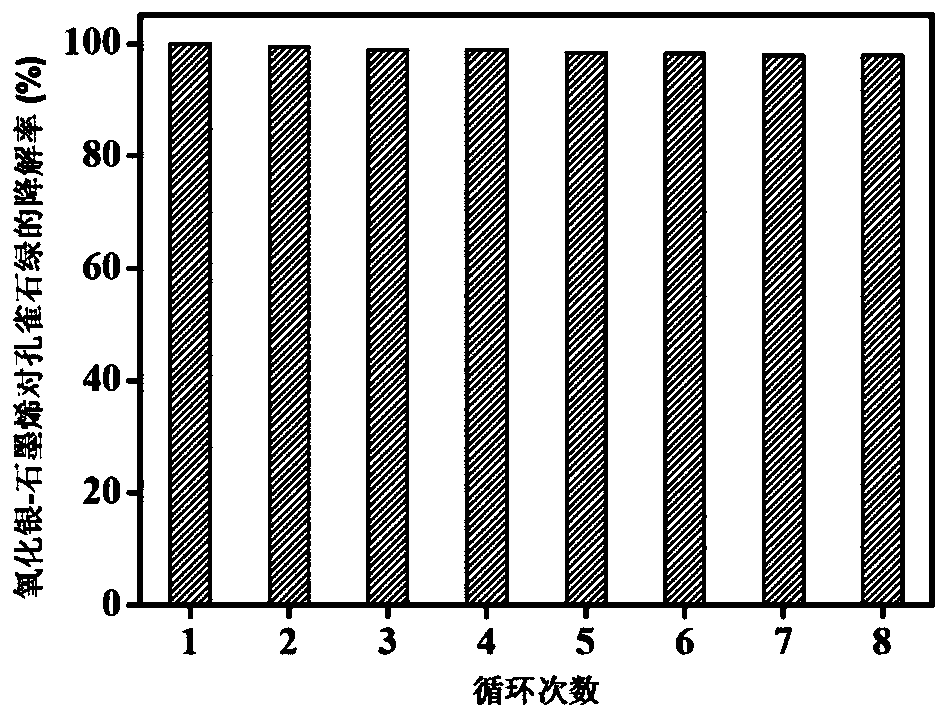

A high-stability, composite material technology, applied in chemical instruments and methods, water treatment of special compounds, metal/metal oxide/metal hydroxide catalysts, etc., can solve rare problems and achieve stable and strong composite structure The effect of photocatalytic activity and easy recycling and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of high stability silver oxide-graphene composite material of the present embodiment, described method comprises the steps:

[0036] Step 1: 200mM / L AgNO 3 Preparation: Weigh 6.795g AgNO 3 In a beaker, add 200mL deionized water and stir for 10min to obtain 200mM / L AgNO 3 solution.

[0037] Step 2: Preparation of graphene powder: Add 80mL of sodium sulfate aqueous solution to a 100mL flask in an ice-water bath, then insert two graphite rods in parallel into the sodium sulfate solution, with a distance of 4cm between the two electrodes, and apply a 10V DC voltage for continuous Electrolyzed for 3 hours to obtain graphene electrolyte. Due to the continuous heat release during the electrolysis process, the temperature of the electrolyte is controlled by ice water at 30-35°C. Take the upper layer graphene electrolyte after standing still, ultrasonically vibrate for 5 minutes in an ultrasonic cleaner, and centrifuge at a speed of 1000r / min for...

Embodiment 2

[0040] The preparation method of a highly stable silver oxide-graphene composite material in this embodiment is basically the same as the preparation method of the silver oxide-graphene composite material in Example 1, the only difference is that step 3 is different.

[0041] Step 3 of this embodiment is specifically as follows:

[0042] Weigh 0.2g of the graphene powder and polyethylene glycol (PEG) in the above step 2 in a 150mL round bottom flask, add 95mL of ethanol and water mixed solvent, the volume ratio is 5:1, and the mixed solution is ultrasonically Make it evenly dispersed. Add 1.3mL of 200mM / L AgNO prepared in step 1 dropwise 3 solution, and then dropwise add 3mol / L aqueous potassium hydroxide solution to adjust the pH value of the mixed solution to 9, corresponding to a silver oxide-graphene composite material with a mass ratio of 15%, and react in an oil bath at 110°C for 1.5h . After the reaction, the resulting precipitate was cooled to room temperature and c...

Embodiment 3

[0044] The preparation method of a highly stable silver oxide-graphene composite material in this embodiment is basically the same as the preparation method of the silver oxide-graphene composite material in Example 1, the only difference is that step 3 is different.

[0045] Step 3 of this embodiment is specifically as follows:

[0046] Take by weighing the graphene powder and polyethylene glycol (PEG) in 0.2g above-mentioned step 2 in 250mL round bottom flask, add the mixed solvent of 120mL isopropanol and water wherein, volume ratio is 5:1, will mix The liquid is ultrasonically dispersed evenly. Add 1.3mL of 200mM / L AgNO prepared in step 1 dropwise 3 Solution, and then dropwise add 3mol / L potassium hydroxide aqueous solution thereinto, adjust the pH value of the mixed solution to 9, correspond to the silver oxide-graphene composite material with a mass ratio of 15%, and react in an oil bath at 120°C for 2h. After the reaction, the resulting precipitate was cooled to room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com