Automatic welding and packaging equipment for glass-encapsulated temperature sensors

A temperature sensor and automatic welding technology, applied in thermometers, thermometer parts, instruments, etc., can solve the problems of not providing a foundation for the equipment and not giving a better solution, so as to improve the utilization rate of silver paste, compact structure, and guarantee The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

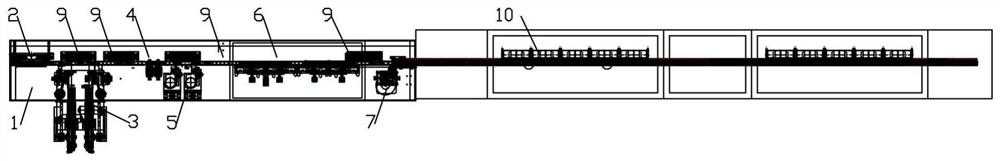

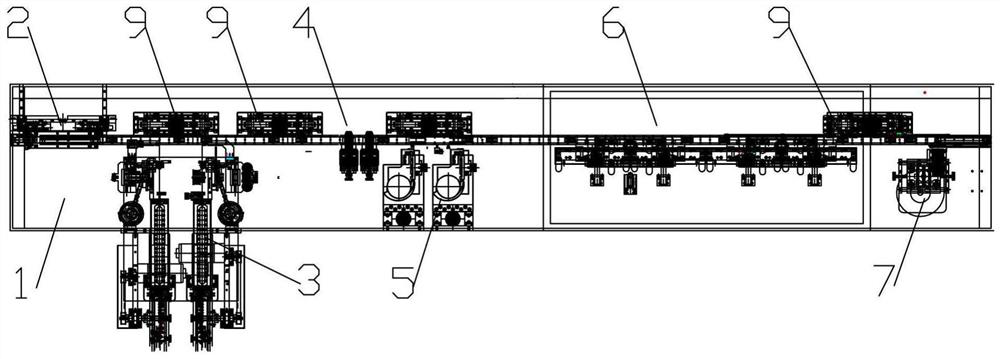

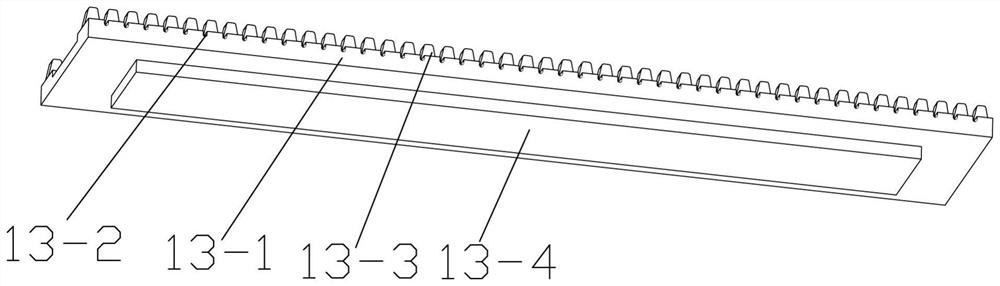

[0095] Such as Figure 1-2 As shown, a glass-encapsulated temperature sensor automatic welding and packaging equipment includes a conveying platform 1, and the conveying platform 1 is sequentially provided with a transfer jig lowering mechanism 2, a straightening and shearing mechanism 3, a silver dipping mechanism 4, Chip welding mechanism 5 , silver drying mechanism 6 , glass bulb inserting mechanism 7 and glass sealing forming mechanism 8 . The above mechanisms respectively complete Dumet silk thread straightening --> Straightening --> Clamping wire --> Cutting --> Jig transfer --> Cutting --> Silver dipping --> Adhesive film --> Preheating -->Baking Silver-->Insert Glass Tube-->Preheating-->High Temperature Forming-->Flip-->Preheating-->High Temperature Forming.

[0096] The straightening and shearing mechanism 3, the silver dipping mechanism 4, the chip welding mechanism 5, and the glass bulb insertion mechanism 7 are intersected with a first transfer jig conveying mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com