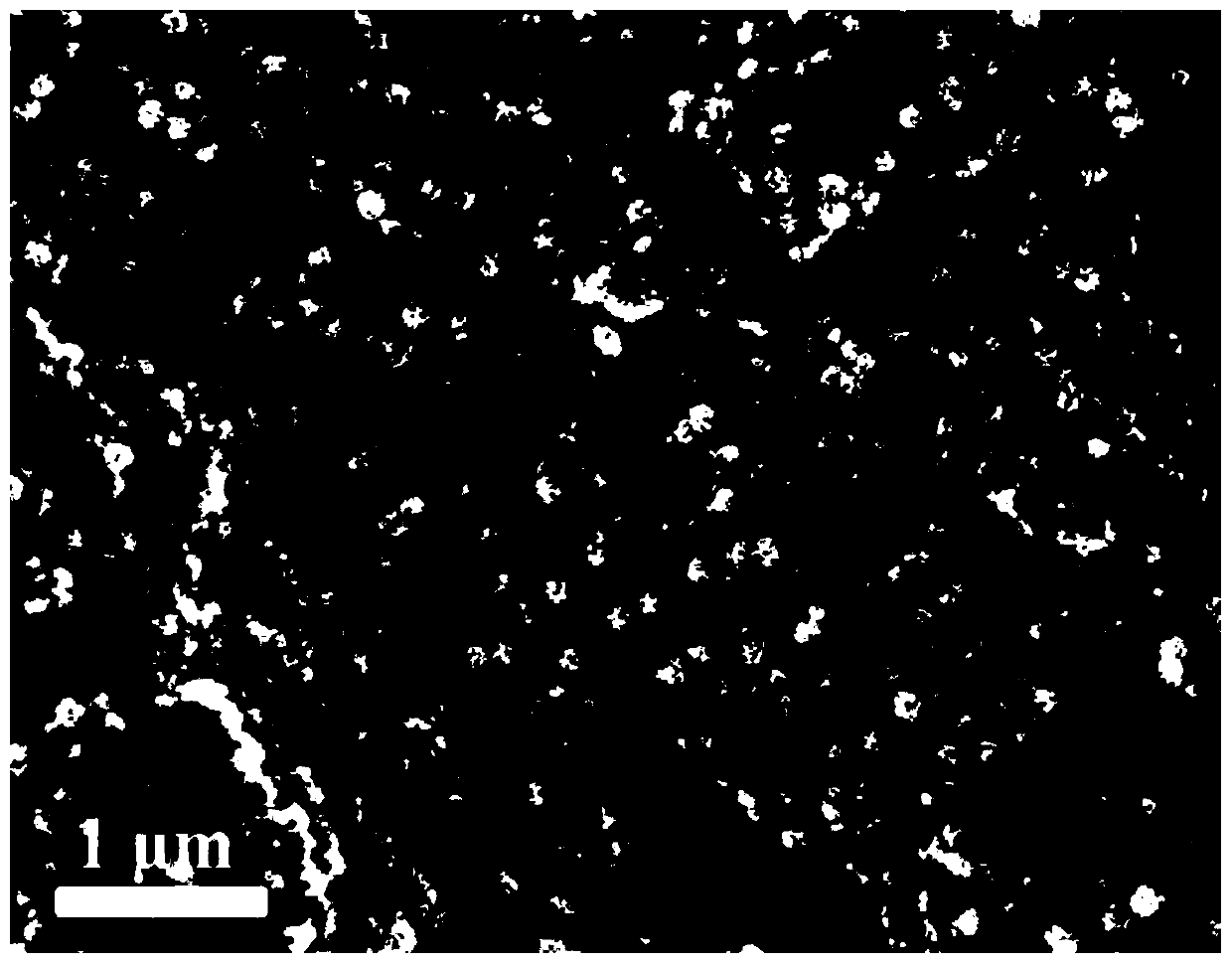

Preparation method of monodisperse porous silica sphere material

A porous silica, monodisperse technology, applied in the direction of silica, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of small pore size and small adjustable range of pore size, and achieve high repetition rate , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a monodisperse porous silica sphere material, comprising:

[0035] (1) Dissolve 2.0g of cetyltrimethylammonium chloride and 0.08mL of triethanolamine in 20mL of deionized water successively, stir at high speed to form a colorless and transparent solution; put the colorless and transparent solution into the reactor Medium; the stirring speed of the above-mentioned high-speed stirring can be selected from 150-800 rpm, and the time can be controlled at 0.25-5h; the stirrer used can be a turbine stirrer, a paddle stirrer, a magnetic stirrer, a magnetic Heated, hinged-blade, or mechanical stirrers;

[0036] Dissolve ethyl orthosilicate in cyclohexane to obtain 8mL organic solution; wherein the concentration of ethyl orthosilicate is 10wt%; add the organic solution to the clear solution to form an oil-water miscible system;

[0037] (2) React the oil-water miscible system in step (1) in an oil bath at a temperature of 60° C. for 8 hours; after the rea...

Embodiment 2

[0041] (1) Dissolve 0.2g of cetyltrimethylammonium bromide and 0.08mL of octylamine in 20mL of deionized water successively, stir at high speed to form a colorless and transparent solution; put the colorless and transparent solution into the reactor Medium; the stirring speed of the above-mentioned high-speed stirring can be selected from 150-800 rpm, and the time can be controlled at 0.25-5h; the stirrer used can be a turbine stirrer, a paddle stirrer, a magnetic stirrer, a magnetic Heated, hinged-blade, or mechanical stirrers;

[0042] Dissolve ethyl orthosilicate in dioxane to obtain 10 mL of organic solution; wherein the concentration of ethyl orthosilicate is 3 wt %; add the organic solution to the clear solution to form an oil-water miscible system;

[0043] (2) React the oil-water miscible system in step (1) in an oil bath at a temperature of 40° C. for 24 hours; after the reaction, collect the precipitate by centrifugation, wash with water and ethanol three times respe...

Embodiment 3

[0047] (1) Dissolve 4.4g of octadecyltrimethylammonium bromide and 0.15mL of dodecylamine in 20mL of deionized water successively, stir at high speed to form a colorless and transparent solution; put the colorless and transparent solution into the reaction In the device; the stirring speed of the above-mentioned high-speed stirring can be selected from 150-800 rpm, and the time can be controlled at 0.25-5h; the stirrer used can be a turbine stirrer, a paddle stirrer, a magnetic stirrer, Magnetic heating stirrer, hinged leaf stirrer, or mechanical stirrer;

[0048] Dissolving fumed silica in octadecene to obtain 10 mL of an organic solution; wherein the concentration of fumed silica is 50 wt %; adding the organic solution to the clarified solution to form an oil-water miscible system;

[0049] (2) reacting the oil-water miscible system in step (1) in an oil bath at a temperature of 80° C. for 2 hours; after the reaction, the precipitate was collected by centrifugation, washed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com