Highly elastic water-stable protein-based/epoxy composite microfiber tissue engineering scaffold and preparation method thereof

A tissue engineering scaffold and ultra-fine fiber technology, applied in tissue regeneration, fiber chemical characteristics, cellulose/protein conjugated rayon, etc., can solve the problems of high toxicity and low efficiency, and achieve low cost, good growth, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

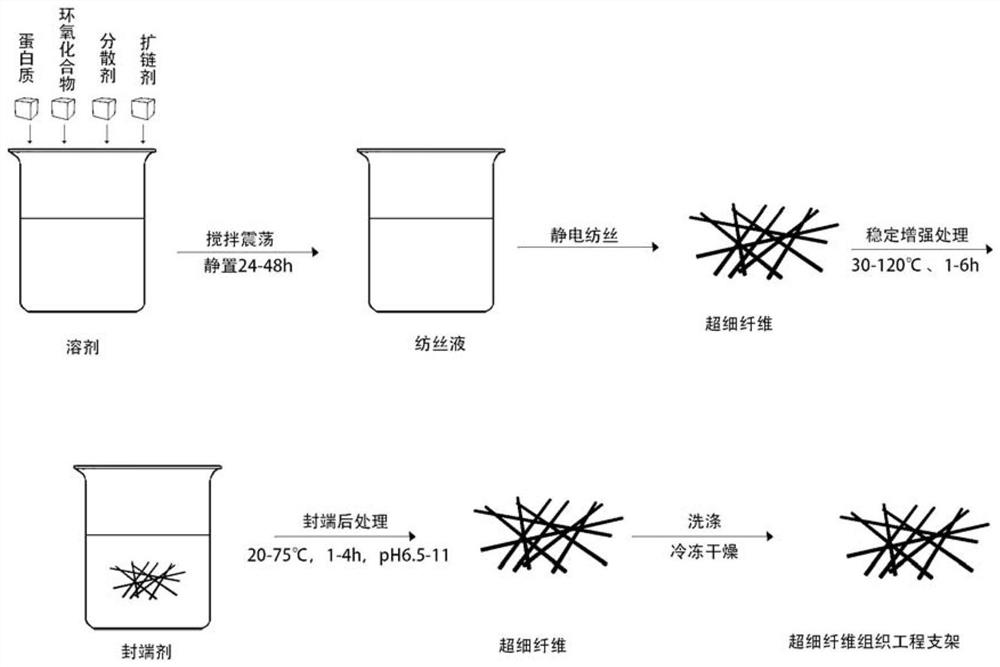

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a protein-based / epoxy composite superfine fiber tissue engineering scaffold:

[0031] Zein and ethylene glycol diglycidyl ether were added into 75% ethanol while stirring at a ratio of 10:3, and the total mass concentration of zein and ethylene glycol diglycidyl ether was 30%. Add polyvinylpyrrolidone to the spinning solution, the proportion is 5% of the zein mass, then stir at 500rpm at room temperature for 30min until it is completely dissolved, and stand at room temperature for 24h to obtain a zein / ethylene glycol diglycidyl ether solution .

[0032]The spinning solution was placed in the solution chamber of a single-needle electrospinning device, the spinning environment was controlled at 25°C, 40% RH, the fiber receiving device was a drum-type receiver, and the rotating speed was 300r / min. The distance from the spinneret is 18cm, the solution injection speed is determined to be 3.0mL / h during the spinning process, and the voltage is maintai...

Embodiment 2

[0035] A preparation method of a protein-based / epoxy composite superfine fiber tissue engineering scaffold:

[0036] Add wheat protein and diethylene glycol diglycidyl ether into 75% acetic acid while stirring at a ratio of 10:3, and the total mass concentration of wheat protein and diethylene glycol diglycidyl ether is 20%. Add sodium dodecylsulfonate and trimethylolpropane into the spinning solution, the proportions are respectively 5% and 1% of the wheat protein mass, then stir at 500rpm at room temperature for 30min until completely dissolved, and stand at room temperature for 24h to obtain wheat protein / diethylene glycol diglycidyl ether solution.

[0037] The spinning solution was placed in the solution chamber of a single-needle electrospinning device, the spinning environment was controlled at 25°C, 50% RH, the fiber receiving device was a drum-type receiver, and the rotating speed was 300r / min. The distance from the spinneret is 16cm, the solution injection speed is ...

Embodiment 3

[0040] A preparation method of a protein-based / epoxy composite superfine fiber tissue engineering scaffold:

[0041] Collagen and 1,4-butanediol diglycidyl ether were added into 75% ethanol while stirring in a ratio of 10:2, and the total mass concentration of collagen and 1,4-butanediol diglycidyl ether was 25%. Add polyvinylpyrrolidone and glycerin to the spinning solution, the proportions are 5% and 1% of the collagen mass, then stir at 500rpm at room temperature for 30min until they are completely dissolved, and stand at room temperature for 32h to obtain collagen / 1,4-butane Alcohol diglycidyl ether solution.

[0042] The spinning solution was placed in the solution chamber of a single-needle electrospinning device, the spinning environment was controlled at 25°C, 50% RH, the fiber receiving device was a drum-type receiver, and the rotating speed was 300r / min. The distance from the spinneret is 16cm, the solution injection speed is determined to be 3.0mL / h during the spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com