Eccentric flour mill for rice processing

A rice processing and eccentric grinding technology, applied in grain processing and other directions, can solve the problems of low grinding efficiency, inconvenient feeding and discharging, and achieve the effects of convenient operation, improved efficiency and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

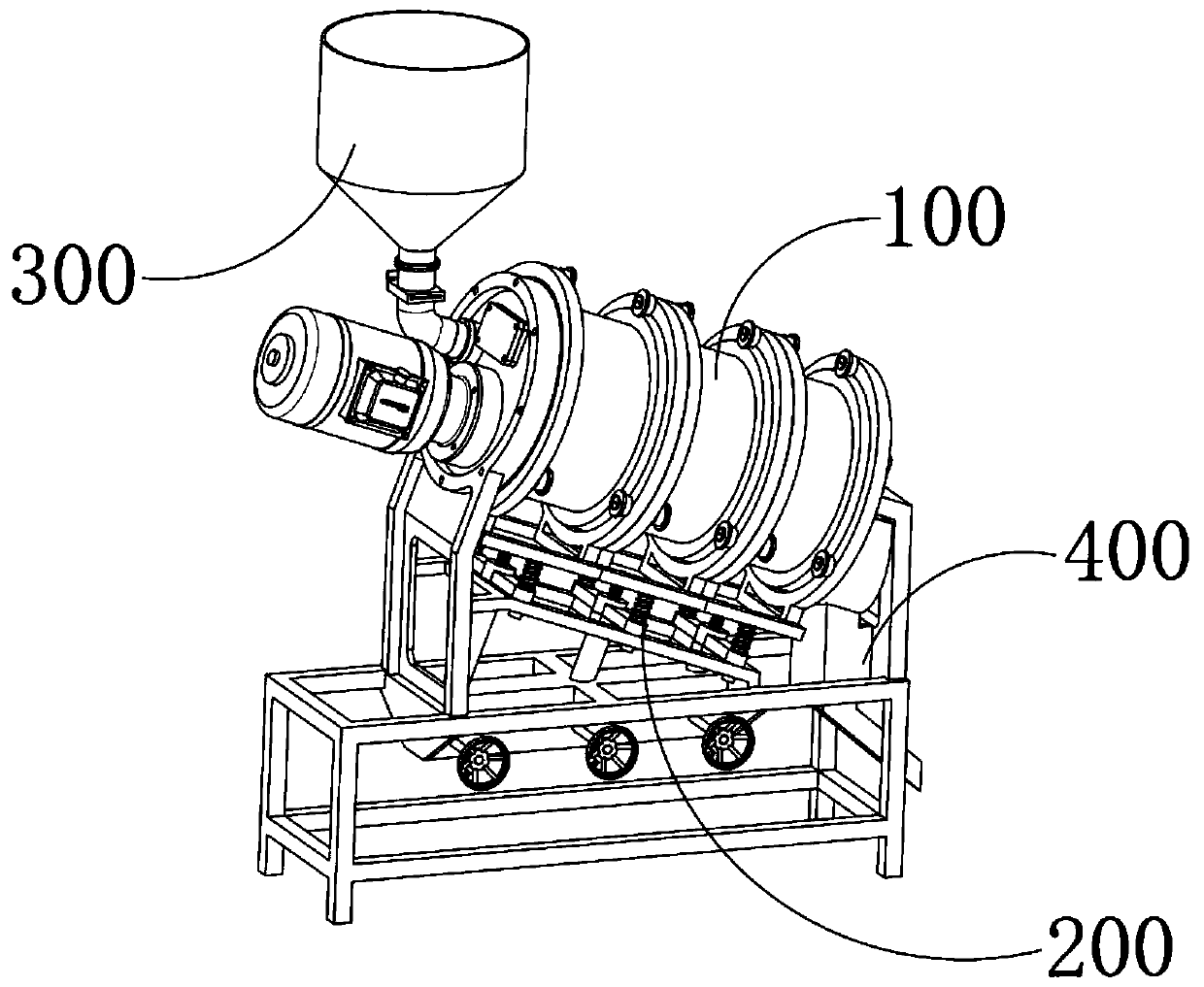

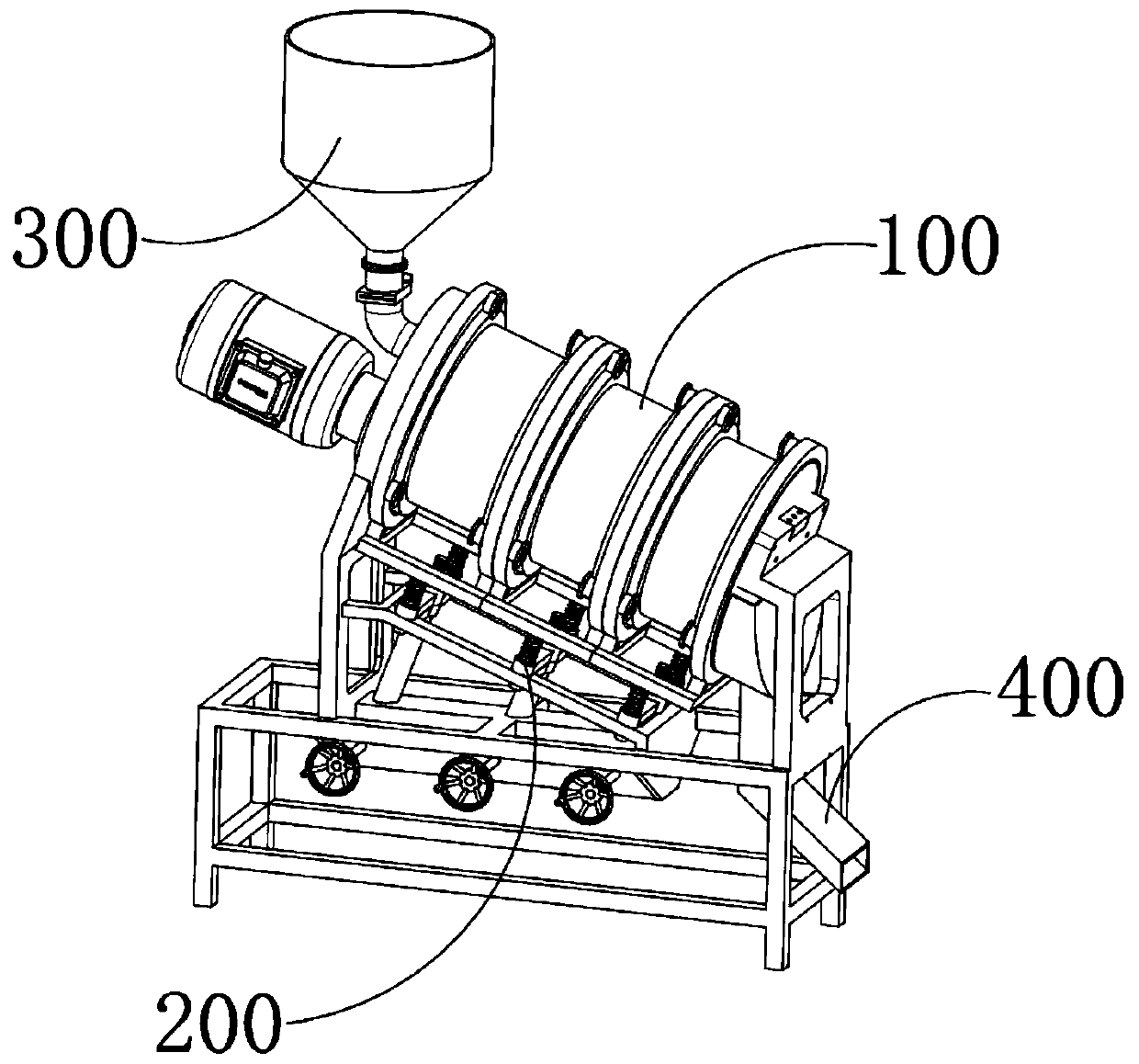

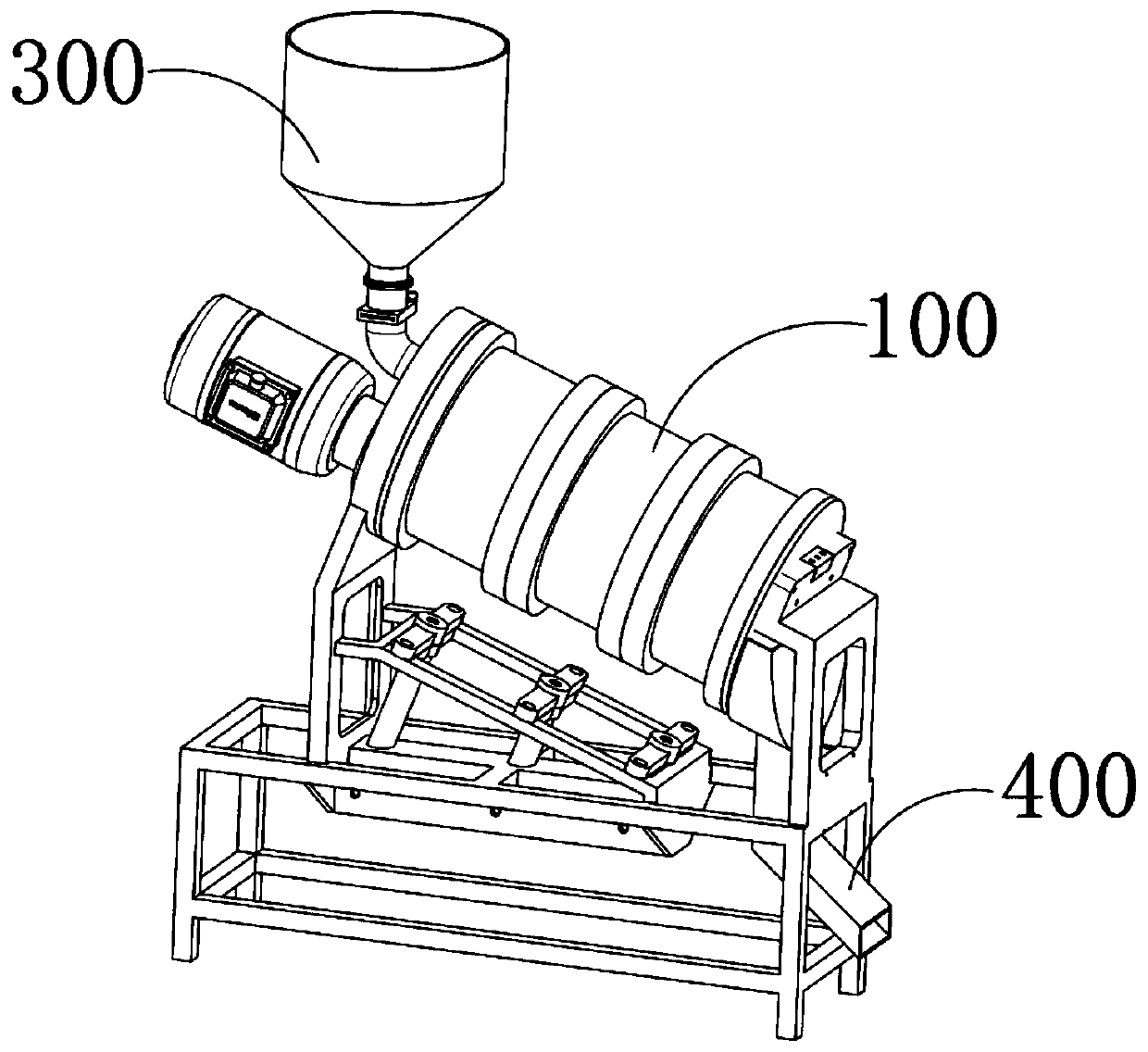

[0056] see Figure 1-23 , an eccentric mill for rice processing, which includes a rolling device 100, a feeding part 300 that can add rice towards the input end of the rolling device 100, and a discharge part 400 that can discharge the rice flour at the output end of the rolling device 100 And the floating support part 200, the rolling device 100 includes an outer cylinder arranged obliquely in the axial direction and a rolling cylinder sleeved in the outer cylinder and the rolling cylinder is located at the eccentric position of the outer cylinder, and the axis line of the rolling cylinder is located outside It is directly below the center line of the cylinder and the outer surface of the rolling cylinder is in conflict with the inner surface of the outer cylinder. The rotation of the rolling cylinder drives the rotation of the outer cylinder to crush and crush the rice located in the conflicting part of the two. The floating support part 200 It is used to adjust the friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com