PEKK individualized implant design and manufacture method for reconstruction of mandible box defect and implant

A mandible and implant technology, applied in the direction of bone implants, joint implants, joint implants, etc., can solve the problems of weak mechanical properties, collapse, etc., to improve the success rate, good osseointegration, and elasticity The effect of excellent and stable modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

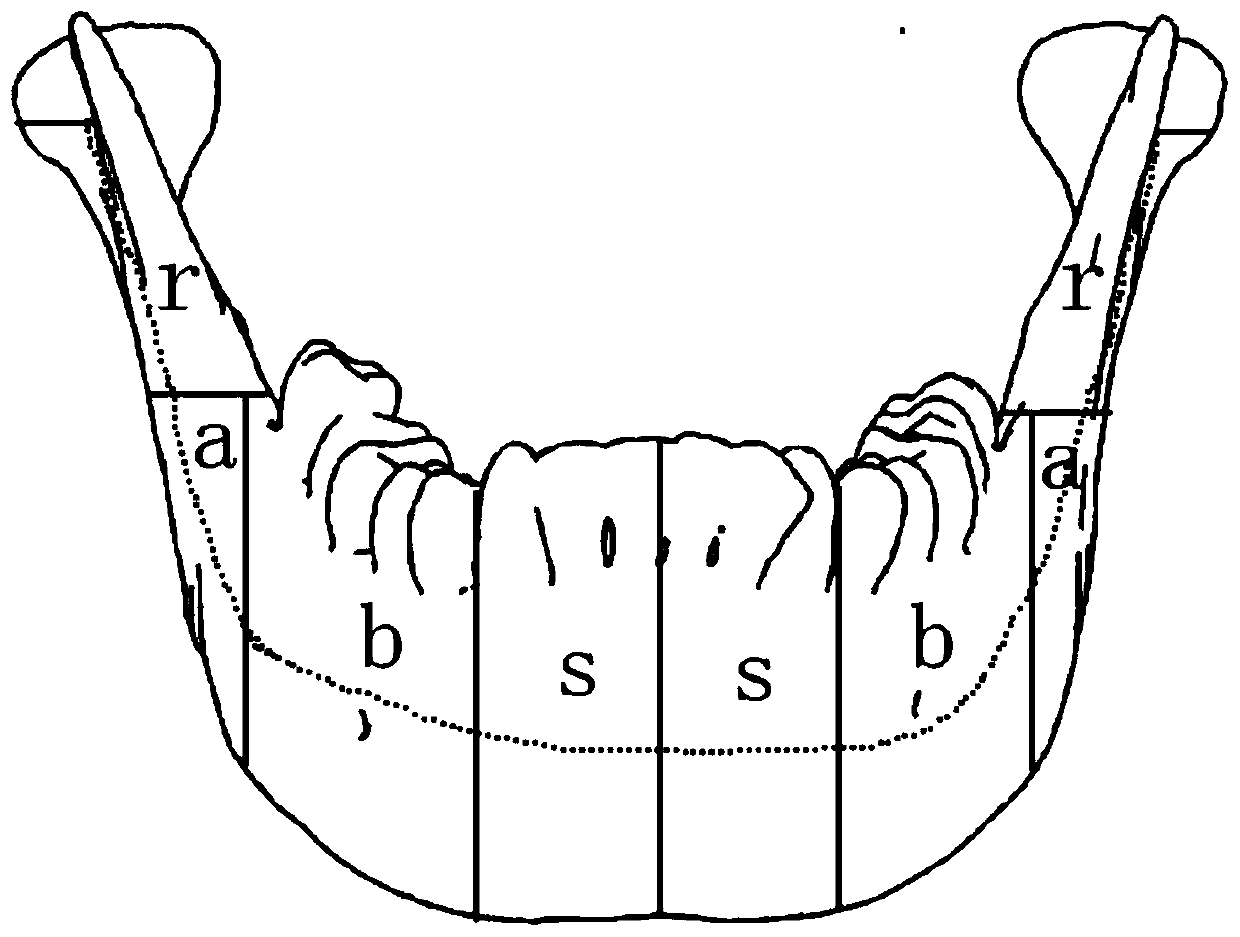

[0058] refer to Figure 1-Figure 17 , a method for designing and manufacturing a PEKK personalized implant for mandibular body box-shaped defect repair, said method comprising the following steps:

[0059] 1) Image acquisition and 3D model establishment, the process is as follows:

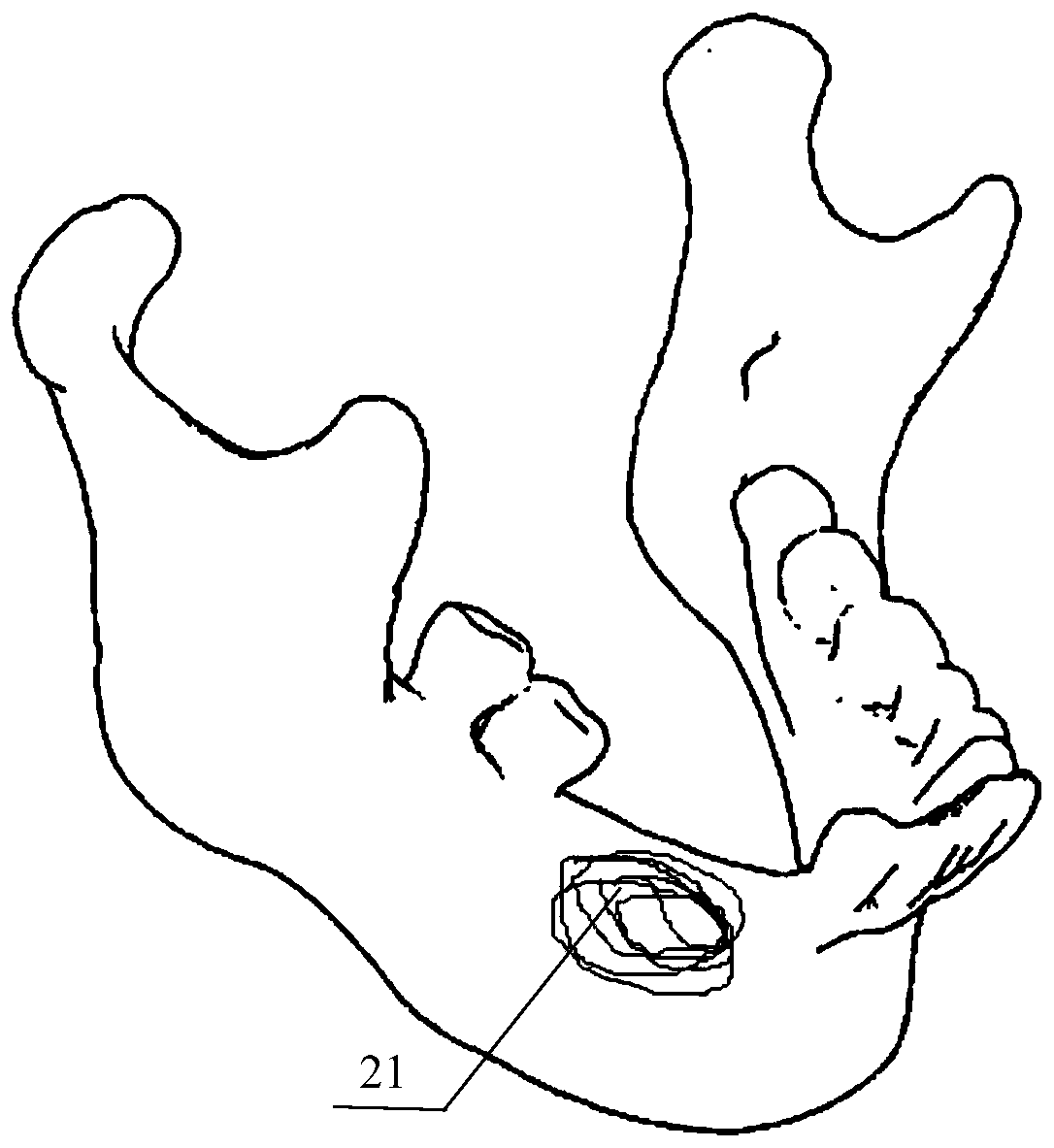

[0060] 1.1) Obtain the patient's oral and maxillofacial CT image, and use medical image processing software such as Mimics to reconstruct the patient's mandibular three-dimensional model, such as figure 2 As shown, the reconstruction model also includes important anatomical structures such as the mandibular nerve canal, and the lesion area is determined21;

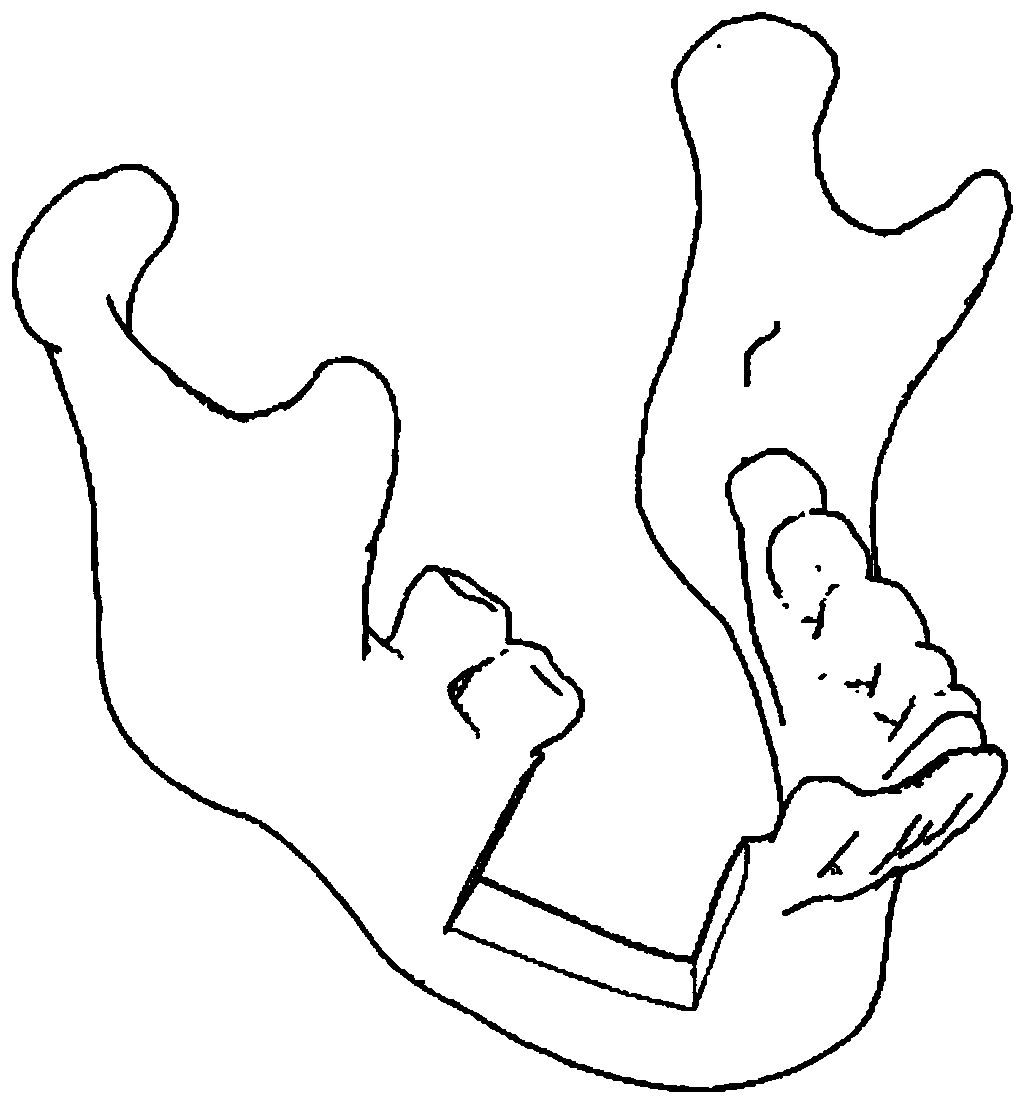

[0061] 1.2) According to the lesion area on the three-dimensional model, the resection plan of the patient's lesion area is designed to obtain a mandibular model with a box-shaped defect of the mandible body, such as image 3 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Rod diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com