Method for controlling and method for designing electrical deionization device

A technology of electrodeionization and control methods, applied in the direction of separation methods, control/manipulation systems, chemical instruments and methods, etc., can solve the problems of increasing the thickness of battery cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

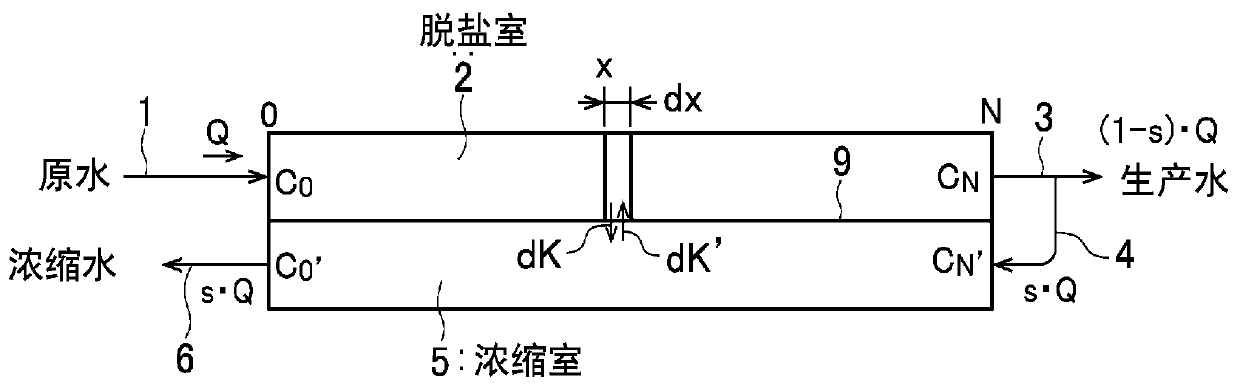

[0110] [Example of the first invention]

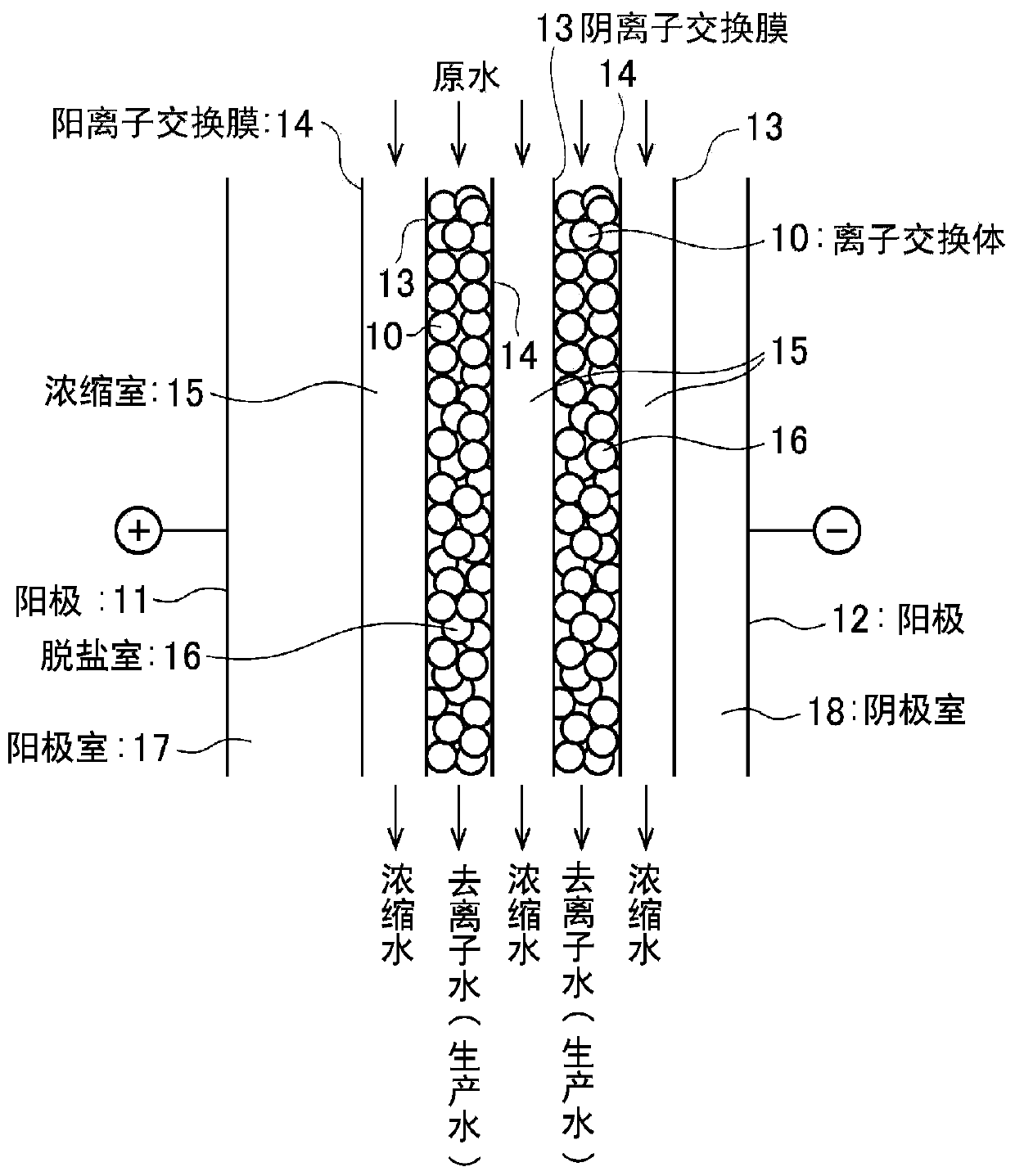

[0111] Use activated carbon-RO-degassing membrane to treat tap water as raw water, and pass it into figure 1 Electrodeionization device. The electrodeionization device has a desalination chamber with three chambers, forming an effective height of 60 cm x width of 22.4 cm x thickness of 5.0 mm. As for the ion exchange resin, a mixed resin of 60% of anion exchange resin and 40% of cation exchange resin was filled only in the demineralization chamber as the ion exchange resin. A spacer is arranged in the concentrating chamber.

[0112] The flow rate Q etc. are as follows.

[0113] Q=120L / Hr (average desalination room per room)

[0114] s=0.2

[0115] Carry out automatic calculation and automatic control according to the formula (9), (10) so that the production water boron concentration becomes 1ppt with a computer.

[0116] At the time of the initial operation, the boron concentration of the feed water was operated at 3 ppb, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap