Ultra-high precision oblique test platform

A test platform and precision technology, which is applied in the direction of measuring inclination, measuring device, mapping and navigation, etc., can solve the problem of difficult traceability of test technology, and achieve the effect of fast measurement speed, stable and reliable length, and convenient traceability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0075] 1. Overall

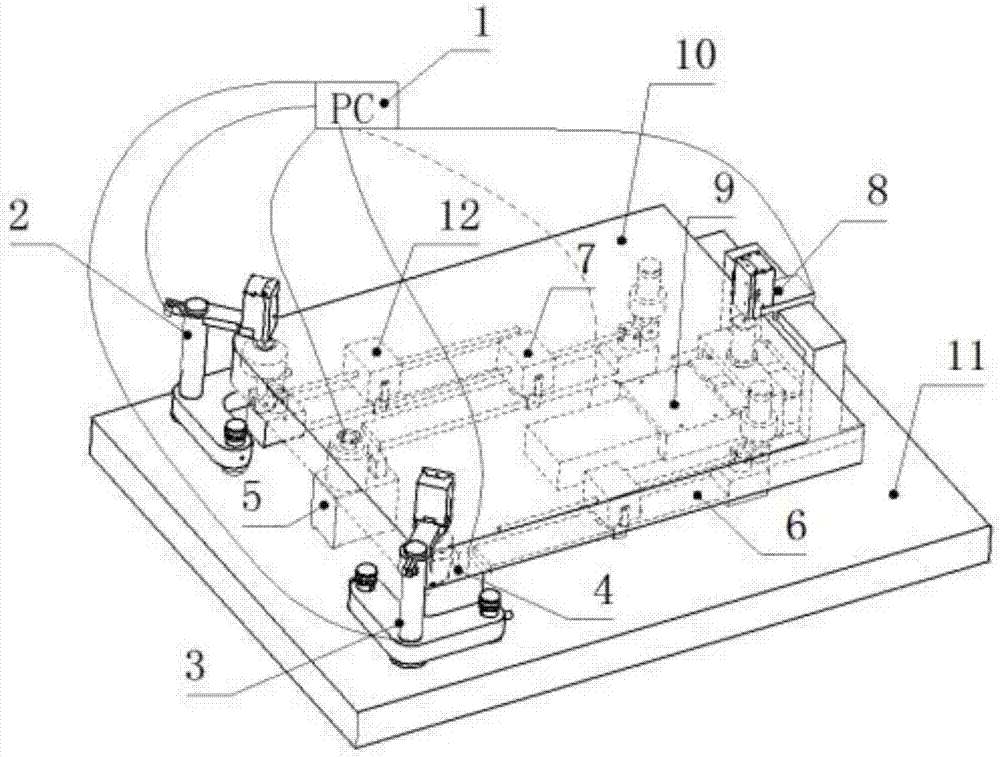

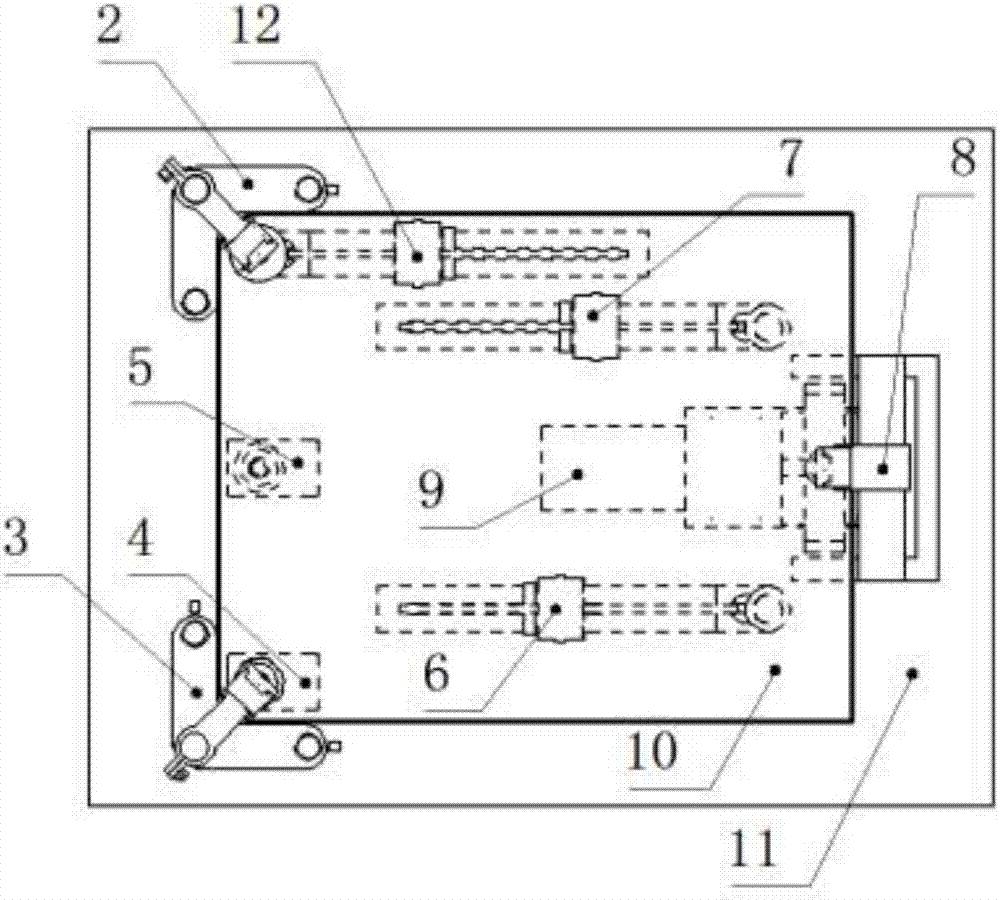

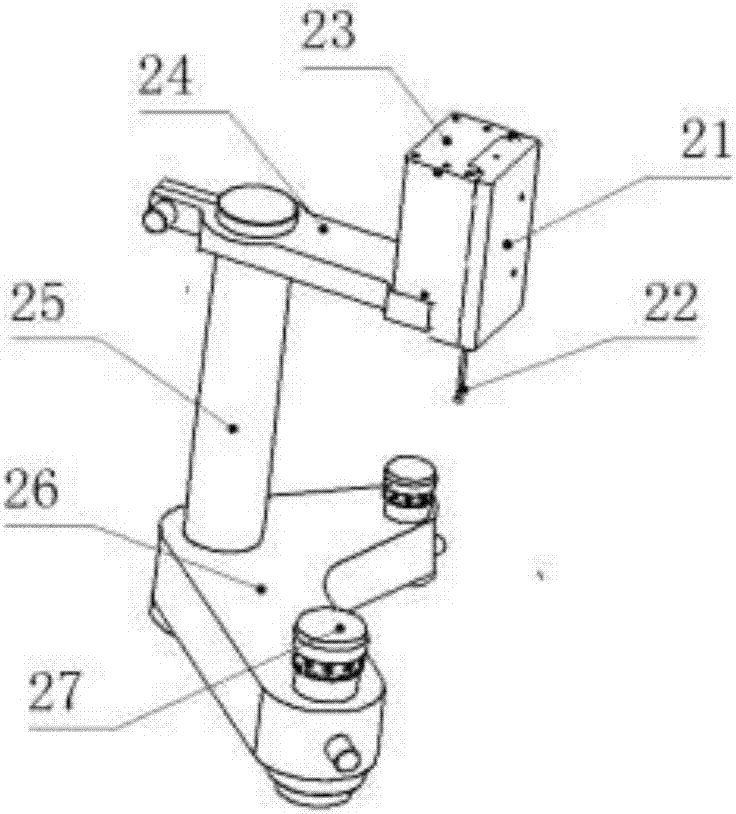

[0076] like figure 1 , 2 , the platform includes a PC controller 1, a first grating ruler measuring mechanism 2, a second grating ruler measuring mechanism 3, a first base 4, a second base 5, a first force balance device 6, a second force balance device 7, a second force balance device 3 grating ruler measuring mechanism 8, linear motor drive mechanism 9, platform panel 10, positioning base 11 and third force balance device 12;

[0077] Its location and connection relationship are:

[0078] The first base 4 and the second base 5 are arranged on the left side bottom of the platform panel 10, and the linear motor driving mechanism 9 is arranged on the right middle position below the platform panel 10, the first base 4, the second base 5 and the linear motor The driving mechanisms 9 are all arranged on the positioning base 11;

[0079] The first grating ruler measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com