Preparation method of single-mode gallium arsenide-based quantum dot laser

A gallium arsenide-based, laser technology, applied in lasers, phonon exciters, laser parts and other directions, can solve the problems of high cost, complex single longitudinal mode laser manufacturing process, and difficulty in mass production, and avoid aluminum oxidation. , reduce complexity and cost, enhance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

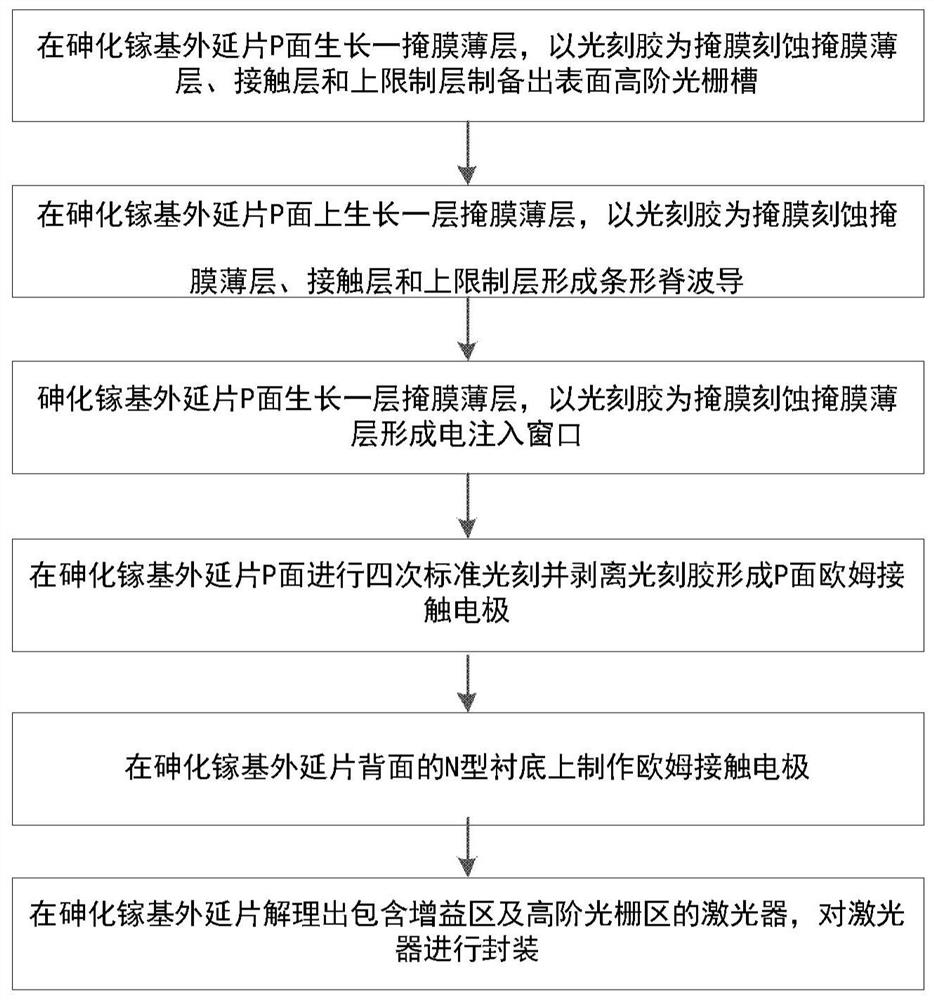

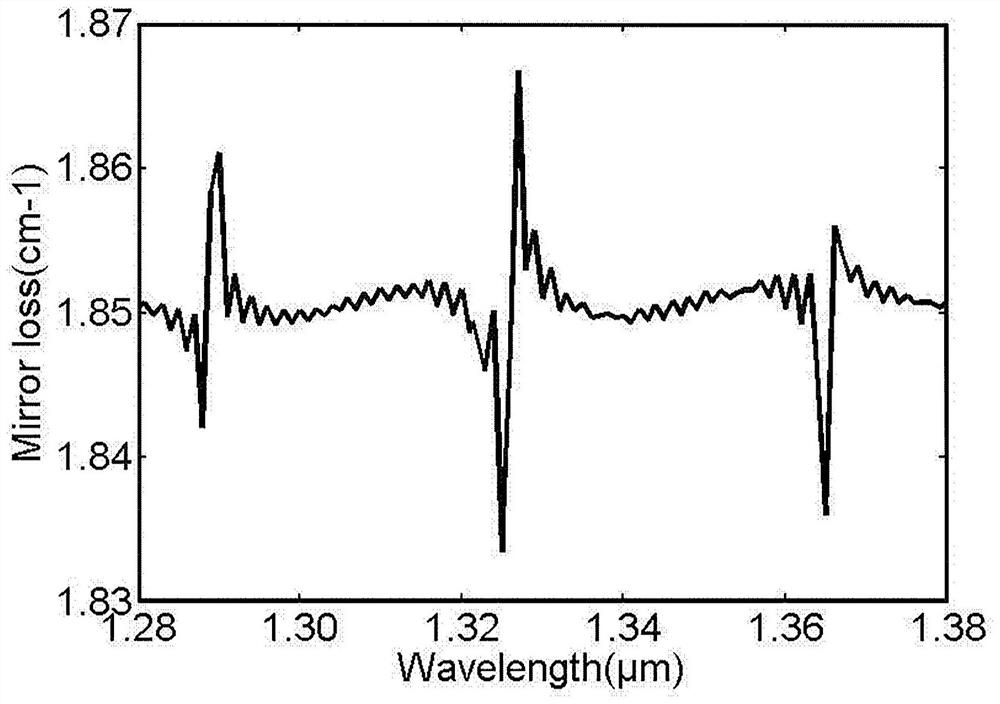

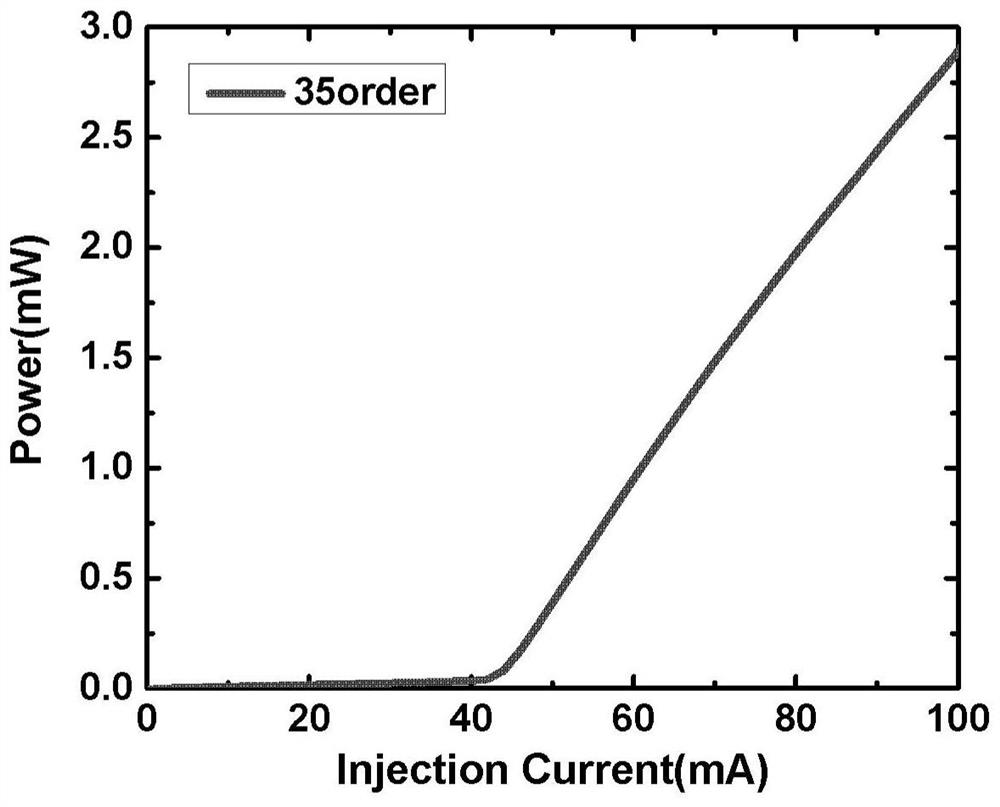

[0039] Such as figure 1 as shown, figure 1 It is a flowchart of a preparation method of a single-mode gallium arsenide-based quantum dot laser according to an embodiment of the present invention. The single-mode gallium arsenide-based quantum dot laser adopts a strip-shaped ridge waveguide structure, including a gain region and a high-order grating region, wherein the In the high-order grating area described above, a series of equal-period grating grooves are deeply etched, and the refractive index modulation is introduced into the Fabry-Perot (FP) cavity, so that the mirror loss of the FP cavity has a minimum value at a specific wavelength. When the device works above the threshold, the point with the smallest mode gain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com