Assembly-type mounting structure of frame partition wall

An installation structure and prefabricated technology, which is applied in the direction of walls, building components, building structures, etc., can solve the problems that wooden keels cannot meet the fire protection requirements, poor sound insulation and heat preservation effects, and inconvenient transportation and handling, etc., and achieve the effect of heat preservation Good, easy to disassemble, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

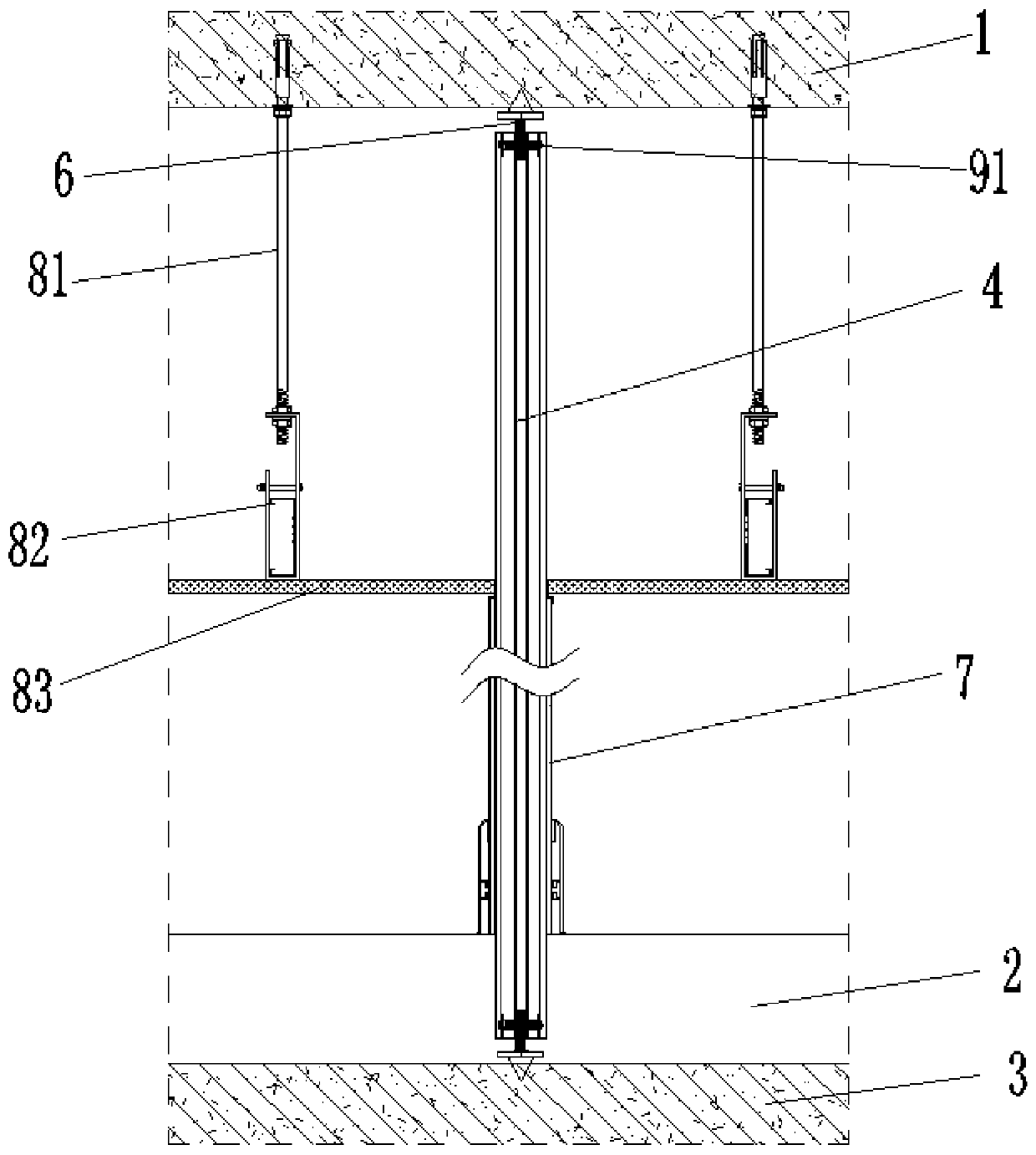

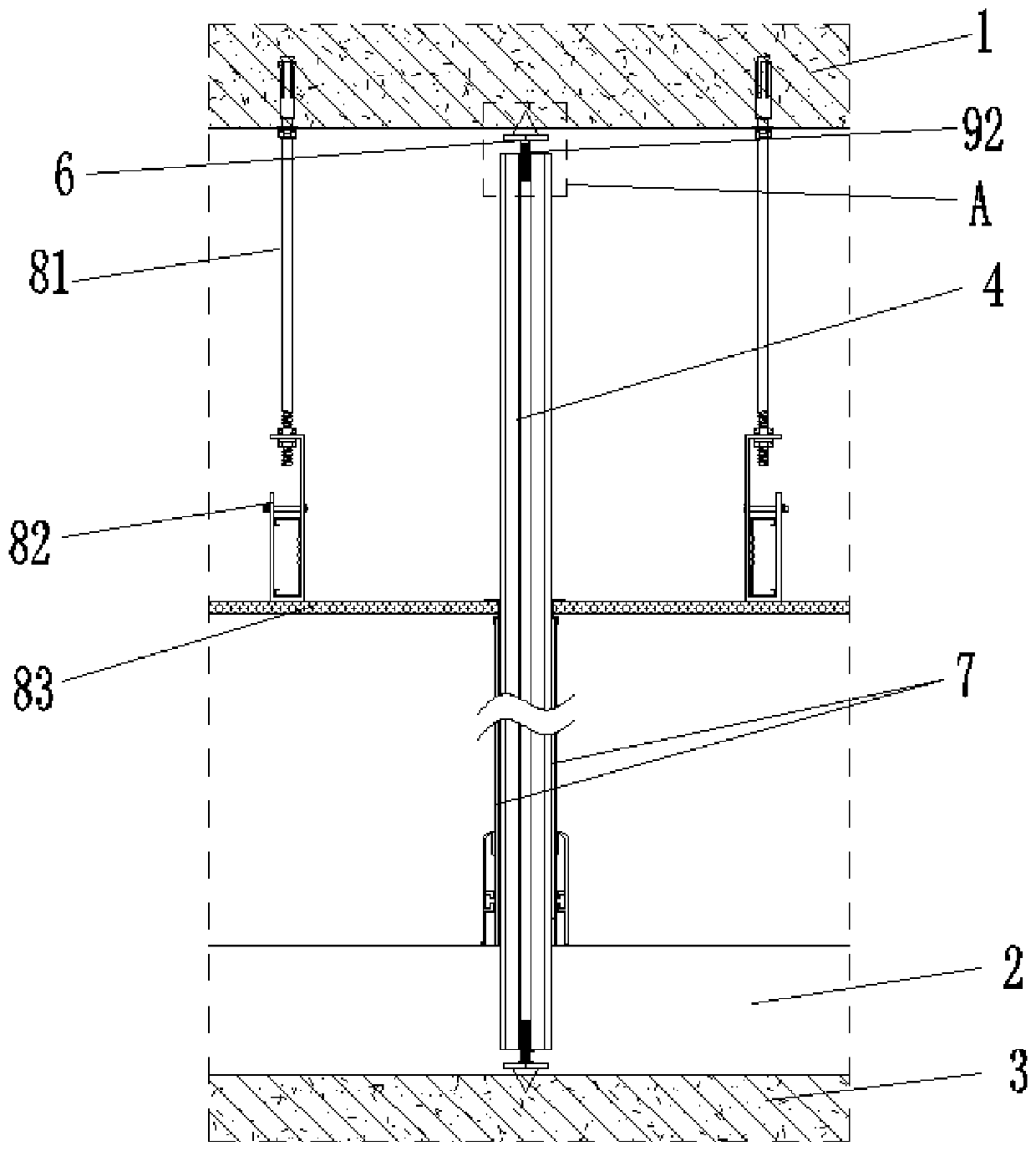

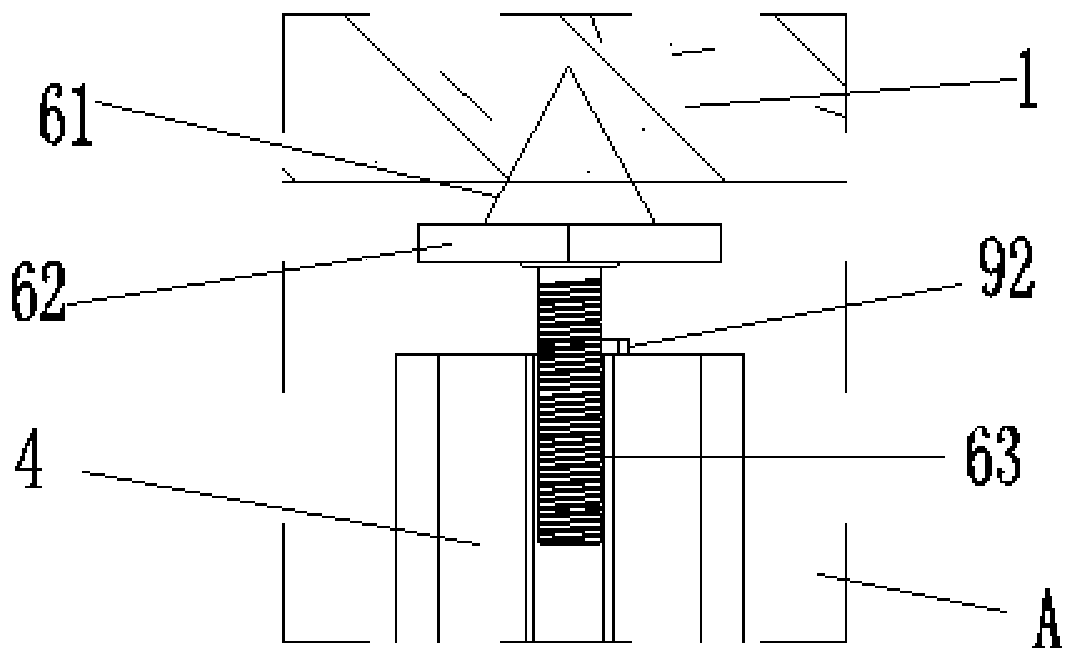

[0037] see Figure 1-2 , Figure 4-6 , the figure shows the installation structure of a prefabricated frame partition wall provided by Embodiment 1 of the present invention, the ceiling assembly, which is located below the wall top 1; the ground decoration layer 2, which is arranged on the ground 3; the partition wall frame, It includes a vertical frame 4, a horizontal frame 5 and a support 6, the horizontal frame 5 is connected to the vertical frame 4, and the two are perpendicular; the vertical frame 4 runs through the ceiling assembly and the ground decoration layer 2; along the length direction, the vertical frame 4 is provided with a connection hole 41 in the center; along the width direction, the edge of the vertical frame 4 is provided with a connection groove 42 and a card groove 43; the support member 6 includes a support top 61, a connection plate 62 and a connection rod 63 connected in sequence, supporting The top 61 connects the wall top 1 and the ground 3, and th...

Embodiment 2

[0049] see Figure 1 to Figure 3 , the figure shows the installation structure of a prefabricated frame partition wall provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the partition wall The frame also includes a fastener, which connects the support 6 and the vertical frame 4; the fastener is a screw 91 or a clamping retaining ring 92; the screw 91 is arranged around the vertical frame 4 and tightens the connecting rod 63; The clamping retaining ring 92 is sleeved on the connecting rod 63 and connected to the top of the vertical frame 4 . Through the setting of the above structure, the connection strength between the support member 6 and the vertical frame 4 can be improved, and the installation effect between the vertical frame 4 and the wall top 1 and the ground 3 can also be improved.

Embodiment 3

[0051] see Figure 1 to Figure 3 , the figure shows the installation structure of a prefabricated frame partition wall provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: support the roof The side of 61 is triangular. Through the setting of the above structure, it is convenient to drive the support top 61 into the wall top 1 or into the ground 3, which is convenient for installation and more firmly connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com