Efficient water purifying agent and preparation method thereof

A water purifying agent, high-efficiency technology, applied in the direction of chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of complex equipment, large dosage, and various types, and achieve improved adsorption performance and unique Secondary pollution and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

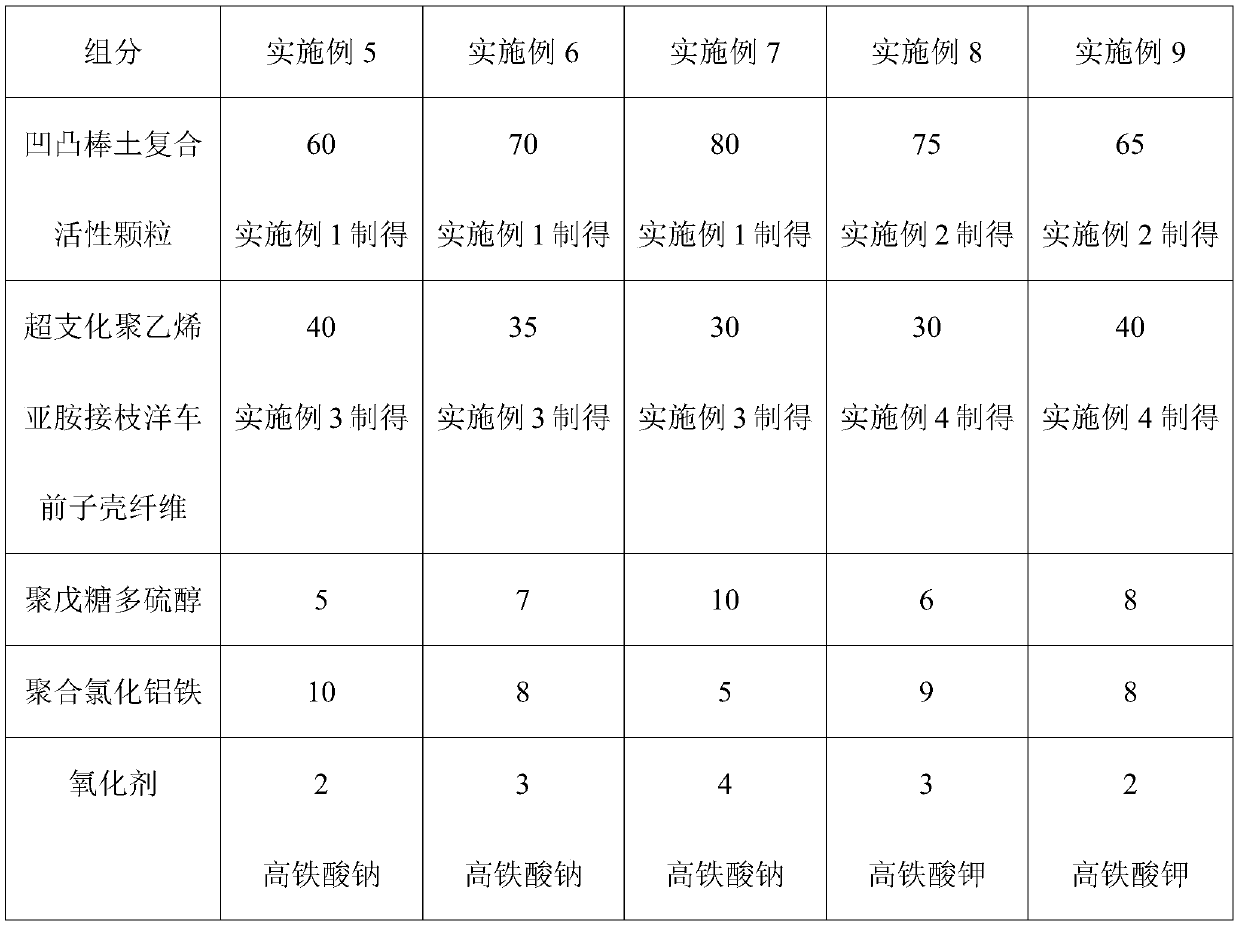

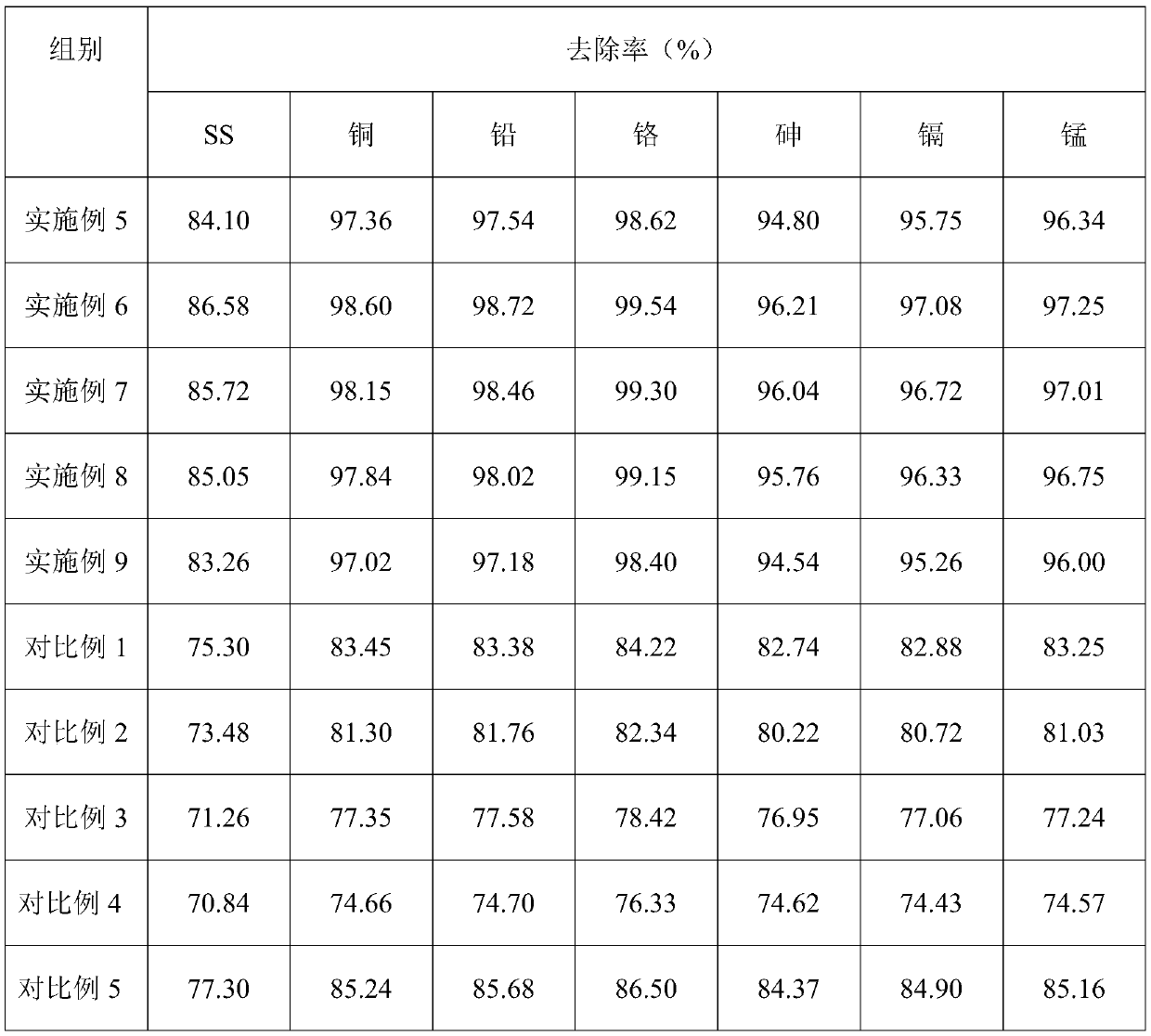

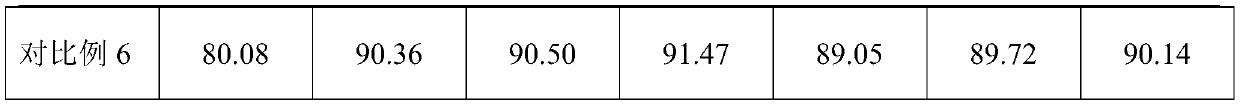

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of attapulgite composite active particles

[0024] Mix attapulgite with hydrochloric acid solution with a concentration of 5mol / L at a ratio of 1g / 10mL, stir and heat to 100°C, activate for 5h, after the reaction, wash with water until the pH is 5.5, centrifuge, and remove the precipitate at 110 Dry at ℃ for 12 hours to obtain pretreated attapulgite, mix the pretreated attapulgite with 20% choline solution in a mass ratio of 3:1, granulate, and activate at 120°C for 2 hours to obtain Attapulgite composite active particles.

Embodiment 2

[0025] Embodiment 2: Preparation of attapulgite composite active particles

[0026] Mix attapulgite with hydrochloric acid solution with a concentration of 5mol / L at a ratio of 1g / 10mL, stir and heat to 100°C, activate for 5h, after the reaction, wash with water until the pH is 5.5, centrifuge, and remove the precipitate at 110 Dry at ℃ for 12 hours to obtain pretreated attapulgite, mix the pretreated attapulgite with 10% choline solution in a mass ratio of 2:1, granulate, and activate at 180°C for 1 hour to obtain Attapulgite composite active particles.

Embodiment 3

[0027] Embodiment 3: Preparation of hyperbranched polyethyleneimine grafted psyllium husk fiber

[0028] (1) Preparation of pretreated psyllium seed husk fiber: the psyllium seed husk powder is added to the sodium hydroxide solution with a mass fraction of 2%, and the mass ratio of the psyllium seed husk powder and the sodium hydroxide solution is 1 : 15; heat treatment 3h at 100 DEG C, cooling, solid-liquid separation, washing deposit, drying, obtains the psyllium seed husk cellulose, and the psyllium seed husk cellulose is added the hydrogen peroxide solution that molar concentration is 0.5mol / L Among them, the mass ratio of the psyllium seed husk cellulose to the hydrogen peroxide solution is 1:2, react at 60°C for 3h under stirring conditions, separate the solid from the liquid, wash the precipitate, dry it, grind it for later use, and obtain the pretreated Psyllium Husk Fiber.

[0029] (2) Preparation of hyperbranched polyethyleneimine grafted psyllium seed husk fiber: t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com