Surface enhancement treatment method for heavy hammer sheet

A surface enhancement and treatment method technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of low bonding strength of the substrate, affecting the stability of use, and the decline of mechanical strength, etc., to achieve the benefit of Cross-linking and fixing, improving the use effect and life, and enhancing the effect of mechanical quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

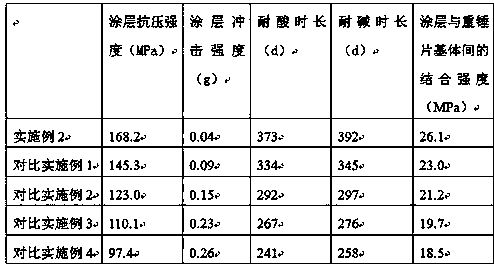

Examples

Embodiment 1

[0032] A surface strengthening treatment method for a heavy hammer, comprising the steps of:

[0033] (1) Surface cleaning treatment:

[0034] Put the hammer piece in acetone and soak it for 8 minutes, take it out, rinse it with deionized water, and dry it for later use;

[0035] (2) Shot peening treatment:

[0036] Put the hammer piece after step (1) into the shot blasting machine for surface shot peening treatment, take it out after completion and blow off the residual particles and impurities on the surface with compressed air for later use;

[0037] (3) Surface plasma treatment:

[0038] Put the hammer piece treated in step (2) into a low-energy plasma processor for plasma treatment, and take it out after 15 minutes for use;

[0039] (4) Coating spraying treatment:

[0040] a. First mix titanium nitride and zirconium dioxide correspondingly according to the weight ratio of 1.5:1, then put them into a roller mixer and mix them for 3 hours, and take them out to get mixed...

Embodiment 2

[0056] A surface strengthening treatment method for a heavy hammer, comprising the steps of:

[0057] (1) Surface cleaning treatment:

[0058] Put the hammer piece in acetone and soak it for 9 minutes, take it out and rinse it with deionized water and dry it for later use;

[0059] (2) Shot peening treatment:

[0060] Put the hammer piece after step (1) into the shot blasting machine for surface shot peening treatment, take it out after completion and blow off the residual particles and impurities on the surface with compressed air for later use;

[0061] (3) Surface plasma treatment:

[0062] Put the hammer piece treated in step (2) into a low-energy plasma processor for plasma treatment, and take it out after 18 minutes for use;

[0063] (4) Coating spraying treatment:

[0064] a. First mix titanium nitride and zirconium dioxide correspondingly according to the weight ratio of 1.8:1, then put them into a roller mixer and mix them for 4 hours, and take them out to get mix...

Embodiment 3

[0080] A surface strengthening treatment method for a heavy hammer, comprising the steps of:

[0081] (1) Surface cleaning treatment:

[0082] First put the hammer piece in acetone and soak for 10 minutes, take it out and rinse it with deionized water once, then dry it for later use;

[0083] (2) Shot peening treatment:

[0084] Put the hammer piece after step (1) into the shot blasting machine for surface shot peening treatment, take it out after completion and blow off the residual particles and impurities on the surface with compressed air for later use;

[0085] (3) Surface plasma treatment:

[0086] Put the hammer piece treated in step (2) into a low-energy plasma processor for plasma treatment, and take it out after 20 minutes for use;

[0087] (4) Coating spraying treatment:

[0088] a. First mix titanium nitride and zirconium dioxide correspondingly according to the weight ratio of 2:1, then put them into a roller mixer and mix them for 5 hours, and take them out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com