Temperature control micro-valve based on liquid crystal and single-stage and multi-stage control systems thereof

A single-stage control and control system technology, applied in the direction of fluid controllers, laboratory containers, laboratory appliances, etc., can solve the problems of difficult processing and integration, difficult precise control, harsh use conditions, etc., to achieve Good dynamic response performance, low processing difficulty and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

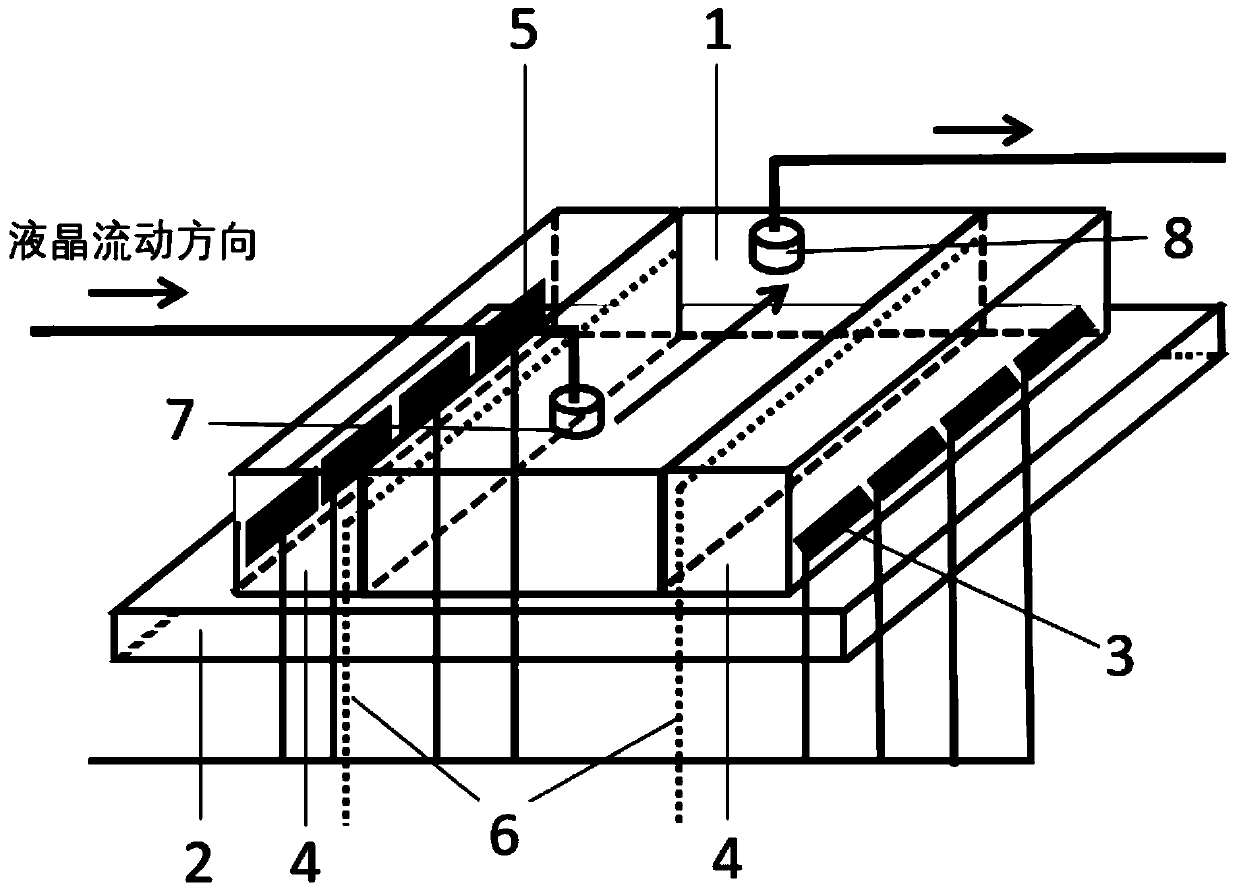

[0033] Such as figure 1 , A temperature-controlled microvalve based on liquid crystal, comprising a microchannel 1, a substrate 2, a liquid crystal and an electric heating wire 3; the microchannel 1 is arranged above the substrate 2; the liquid crystal is arranged in the microchannel 1 and can be along the channel direction Flow; The heating wire 3 is arranged outside the microchannel wall 4 on either side of the vertical liquid crystal flow.

[0034] The liquid crystal flows in from the inlet 7 of the microchannel 1 and flows out from the outlet 8, and the liquid crystal flows in different directions after flowing out from the outlet 8.

[0035] The heating wire can be arranged outside the microchannel wall 4 by bonding or other fixing methods.

[0036] When in use, by turning on the heating wire 3 to heat one side of the microchannel wall 4, the temperature of the liquid crystal in the microchannel 1 on this side rises, and there is a temperature difference between it and the other...

Embodiment 2

[0045] Such as image 3 The heating wire 3 and the cooling fins 5 are both block-type and independently controlled structures, which can control heating and cooling in blocks / sections, so as to control the temperature difference adjustment process more accurately and easily.

Embodiment 3

[0047] Such as Figure 4 The microchannel 1 may contain multiple subchannels superimposed up and down or left and right. The liquid crystal flows into the microchannel 1 from the inlet 7 and then flows into each subchannel respectively. The temperature control elements are simultaneously arranged in each subchannel of the microchannel 1. On the outside, in order to realize the multi-channel separate regulation of the flow in the microchannel.

[0048] On the basis of embodiment one, two or three, such as Figure 5 , A single-stage control system based on liquid crystal temperature-controlled microvalves. The control loop of the single-stage control system includes a temperature-controlled microvalve 9, temperature sensors and control elements. The liquid crystal flows out from the outlet of the temperature-controlled microvalve 9. The back flow is in different directions, namely a-direction channel and b-direction channel. The single-stage control system based on the liquid cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com