Treatment device and process integrating VOCs purification and denitration

A treatment device and treatment process technology, applied in chemical instruments and methods, incinerators, lighting and heating equipment, etc., can solve problems such as increased operating energy consumption, non-compliance with process requirements, etc. Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

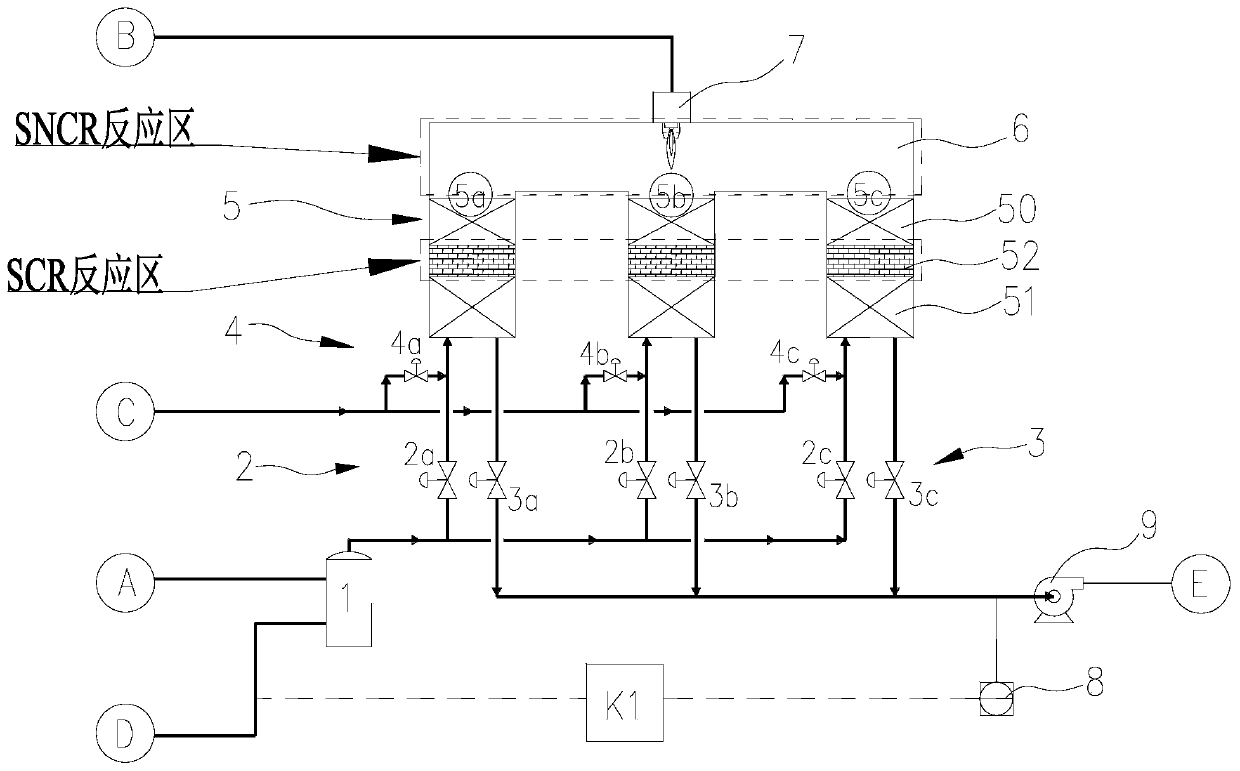

[0065] Such as figure 1 As shown, it is a treatment device integrating VOCs purification and denitrification, including an RTO reactor, which includes a combustor 6 and several regenerators 5 connected to each other, and the combustor 6 is located in the regenerator 5 the upper part; any regenerator 5 includes an upper regenerator 50, a lower regenerator 51 and an SCR catalyst bed 52 in the middle; Valve 3, a purge valve 4; the input end of the inlet valve is connected to the buffer tank 1, and the buffer tank 1 is connected to the VOCs waste gas A pipeline and the ammonia gas D pipeline; the input end of the purge valve is connected to the purge tank Gas supply pipeline; the top of the combustion chamber 6 is also provided with a burner 7, and the input end of the burner 7 is connected to the fuel gas B pipeline.

[0066] In this embodiment, through the innovative device design, firstly, a buffer tank 1 is set up so that VOCs waste gas A and ammonia gas D are mixed before en...

Embodiment 2

[0073] This embodiment is a process method integrating VOCs purification and denitrification, combining figure 1 shown, including the following steps:

[0074] S1, heat release stage of heat accumulator: both VOCs waste gas A and ammonia gas D are passed into the buffer tank 1, and after being fully mixed in the tank (to make quantitative NH 3 and VOCs waste gas are uniformly mixed in the tank through the distributor before entering the RTO reactor), and enter any regenerator 5 through the intake valve 2, the lower regenerator 51 and the upper regenerator 50 in the regenerator 5 The exhaust gas is heated step by step; at this time, the regenerator is in a heat release state;

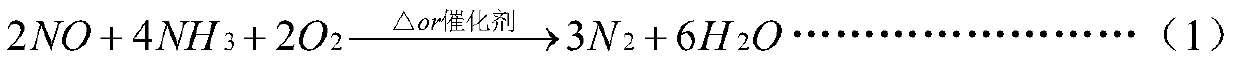

[0075] S2, VOCs oxidation reaction and SNCR reaction stage: the exhaust gas enters the combustion chamber 6 after being heated by the regenerator, and the temperature in the combustion chamber 6 is controlled at 650-800°C, so that the VOCs exhaust gas A in the mixed gas is fully oxidized into CO 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com