Tin-plated copper terminal material, terminal and wire end structure

A tinned copper and terminal technology, applied in the direction of circuits, contact parts, conductive materials, etc., can solve the problems of poor productivity, low durability, poor adhesion between the anti-corrosion layer and Sn plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

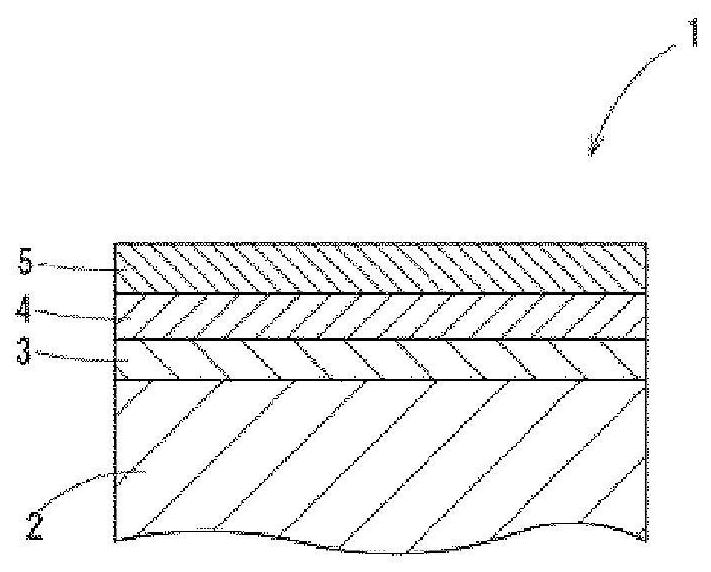

[0072]A copper plate of C1020 (oxygen-free copper) is used as the base material, and after degreasing and pickling, nickel plating or nickel alloy plating (only for samples 13 to 16 and 18) to form the base layer is sequentially performed, and an intermediate zinc layer is formed. The galvanized treatment or galvanized alloy treatment (except sample 17), the tin layer (tin alloy treatment or) tin-plated treatment, to prepare samples 1 to 19. The conditions of the main plating treatment performed on each sample are as follows.

[0073] The zinc content of the intermediate zinc layer is adjusted by changing the ratio of zinc ions in the zinc alloy plating solution to the added alloy element ions. For example, the following nickel-zinc alloy plating treatment conditions are an example in which the zinc concentration in the intermediate zinc layer is 85% by mass (sample 15).

[0074] The sample 17 was not subjected to any one of the nickel plating treatment, the zinc plating trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com