Crystallization method for aluminum fluoride production

A technology of aluminum fluoride and aluminum fluoride water, which is applied in the preparation and application of fine chemicals, can solve problems such as poor crystallization effect and poor filtration effect, and achieve the goals of lowering temperature, increasing crystallization effect, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

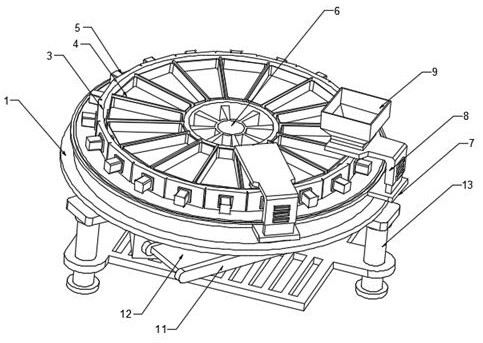

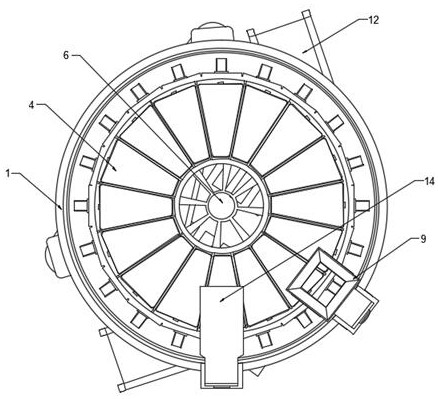

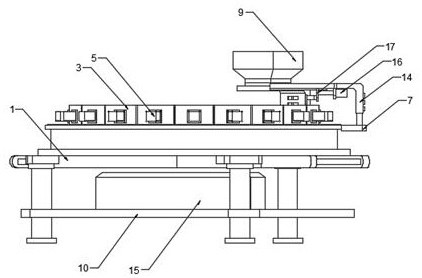

Image

Examples

Embodiment 1

[0045] A crystallization method for aluminum fluoride production, comprising the steps of:

[0046] S1, react the fluosilicic acid and aluminum hydroxide placed in the anticorrosion storage tank to generate aluminum fluoride-silica gel slurry;

[0047] S2. Send the generated aluminum fluoride-silica gel slurry to the belt filter through the filter pump, and separate the aluminum fluoride supersaturated solution from the silica gel under the negative pressure of the vacuum pump; the aluminum fluoride supersaturated solution enters the crystallization tank The crystallization of aluminum fluoride trihydrate is generated, and the silica gel enters the synthesis tank of silica gel containing cryolite;

[0048] S3. Put the supersaturated solution of aluminum fluoride filtered by silica gel into the crystallization tank with steam at 90°C and keep it for 4-6 hours to generate aluminum fluoride trihydrate crystals;

[0049] S4. The solid-liquid mixture after crystallization is place...

Embodiment 2

[0051] On the basis of Embodiment 1, the anticorrosion storage tank is a plastic storage tank 36, and the plastic storage tank 36 is a hollow body with a liquid inlet pipe 37 on the top and a liquid outlet pipe 38 on the bottom, and the liquid inlet pipe 37 and the liquid outlet pipe 38 is provided with a valve, the cavity of the plastic storage tank 36 is provided with an annular partition 39 to separate the cavity into a cooling zone 40 and a storage zone 41, cooling liquid is provided in the cooling zone 40, and the top of the cooling zone 40 is provided with The cooling liquid inlet pipe 42, the bottom is provided with the cooling liquid outlet pipe 43, the cooling liquid inlet pipe 42 and the cooling liquid outlet pipe 43 are provided with valves, when storing the fluorosilicic acid solution, in the cooling zone 40, a Cooling the solution can reduce the temperature of the fluorosilicic acid solution.

[0052] Example 2

[0053] On the basis of Embodiment 1, the side wall...

Embodiment 3

[0055] On the basis of Embodiment 1, the outer wall of the plastic storage tank 36 is wrapped with a first reinforced outer wall 45, and a reinforcing rib is arranged between the first reinforced outer wall 45 and the outer wall 36 of the storage tank; the outer wall of the first reinforced 45 is provided with anti-collision A buffer spring 47 is arranged between the plate 46 and the anti-collision plate 46 and the first reinforced outer wall 45, which can protect the plastic storage tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com