Method for preparing carbon-based Pt alloy catalyst through H2 gas phase thermal reduction

An alloy catalyst and catalyst technology, applied in the field of electrochemical catalysis, can solve the problems of low utilization rate of Pt and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

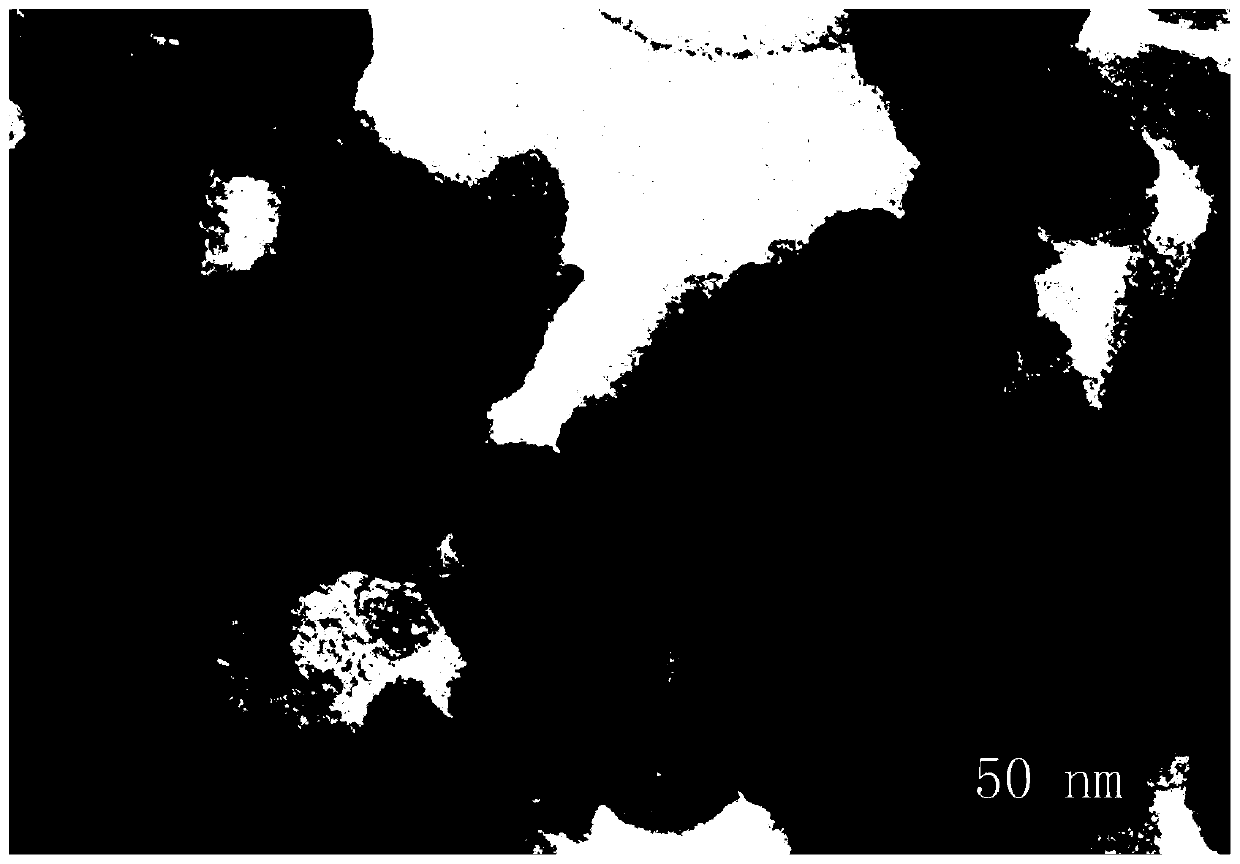

[0059] Take 10mL of 0.017mol / L H 2 PtCl 6 aqueous solution, add 4g NH 4 Cl precipitant, stirred at room temperature for 4 hours to obtain primary sediment A; take 2mL of 0.1mol / L CoCl 2 Solution, add 1g oxalic acid, 4mL deionized water, stir at room temperature for 4h to obtain primary sediment B; mix A and B suspensions, add 50mg carbon powder XC-72 aqueous solution, mix and stir for 4h, centrifuge, dry at 80°C, and h 2 / N 2 (20%) pyrolysis and reduction in the mixed gas, the temperature is 350°C, the time is 4h, the heating rate is 5°C / min, after the reaction is completed, use N 2 Replace the H in the reaction furnace 2 / N 2 Mixed gas, and take out the sample, so as to obtain the highly active H 2 Pt alloy catalyst prepared by thermal reduction method.

Embodiment 2

[0061] Take 10mL of 0.017mol / L H 2 PtCl 6 aqueous solution, add 4g NH 4 Cl, 4g ammonium carbonate, 10mL deionized water, stirred at room temperature for 4h to obtain the primary sediment A'; take 2mL 0.1mol / L CoCl 2 Solution, add 2g oxalic acid, 1g urea, 15mL deionized water, stir at room temperature for 4h, obtain primary sediment B'; mix A' and B' suspensions, add 50mg carbon powder XC-72 aqueous solution, mix and stir for 4h, centrifuge , dried at 80°C, in H 2 / N 2 (20%) pyrolysis and reduction in the mixed gas, the temperature is 350°C, the time is 4h, the heating rate is 5°C / min, after the reaction is completed, use N 2 Replace the H in the reaction furnace 2 / N 2 Mixed gas, and take out the sample, so as to obtain the highly active H 2 Pt alloy catalyst prepared by thermal reduction method.

Embodiment 3

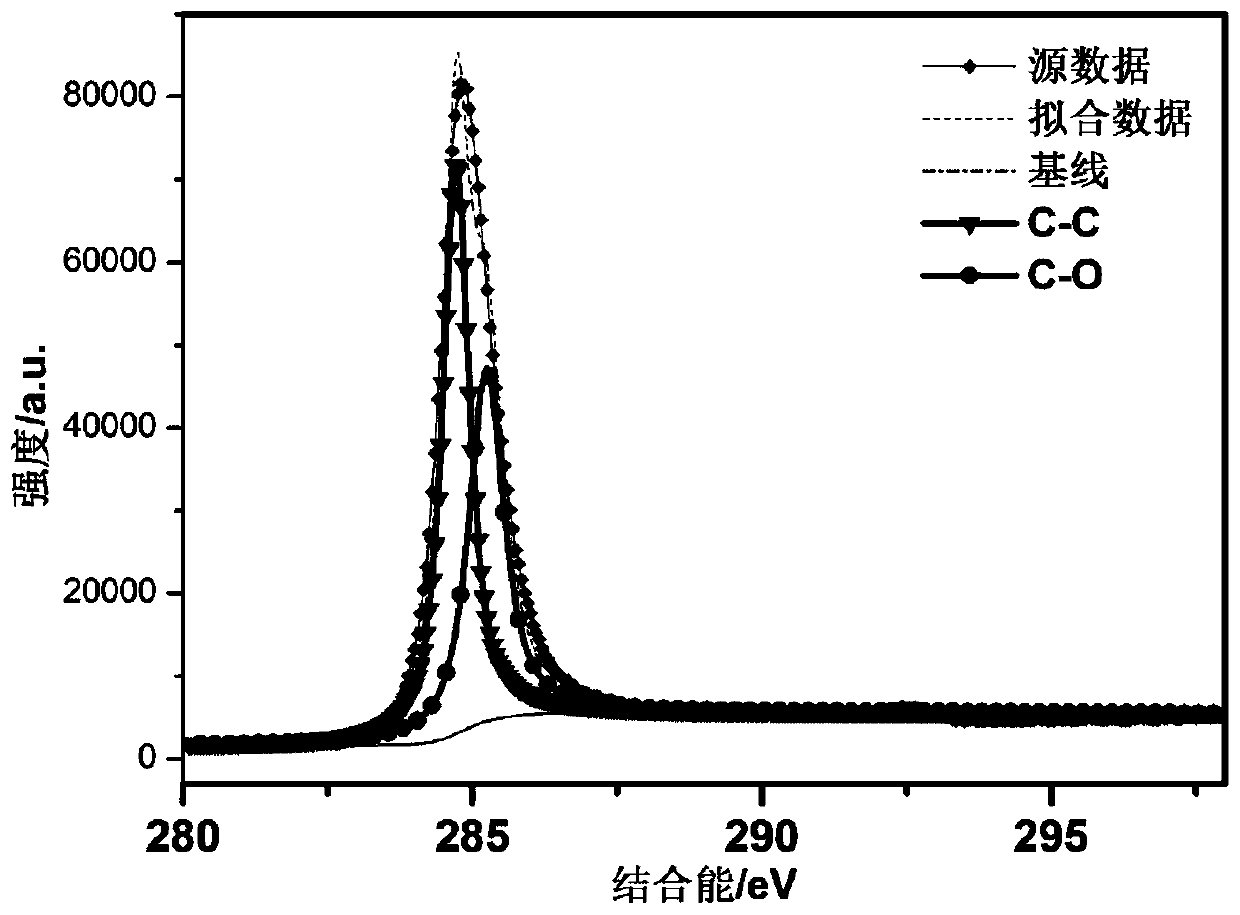

[0063] Electrochemical tests were performed in a three-electrode system to characterize the oxygen reduction activity of the catalysts. The electrolyte solution of this system is 0.1mol L -1 HClO 4 , the counter electrode is a Pt sheet electrode, the reference electrode is a saturated calomel electrode, and the cyclic voltammetry test electrolyte solution is N 2 Saturation, the test system is Gamry3000; ORR test solution is O 2 saturation. Preparation of the catalytic layer of the rotating disk electrode membrane: 40% Pt / C catalyst: 5mg catalyst, 2.5mL isopropanol, ultrasonication; add 50 μL of 5wt% Nafion solution, ultrasonication, take 3.2 μL of the above dispersed slurry and coat it on a rotating disk electrode The disc electrode surface, as the working electrode. Due to the low loading of PtCo / C catalyst, preparation of membrane catalyst layer: 5mg catalyst, 2.5mL isopropanol, ultrasonication; add 50μL of 5wt% Nafion solution, ultrasonication, take 10μL of the above di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com