A method and application of low-cost preparation of lithium iron phosphate cathode material

A technology for lithium iron phosphate and positive electrode materials, which is applied in the direction of phosphate, phosphorus oxyacids, chemical instruments and methods, etc., can solve the problems of high price of lithium iron phosphate materials, difficult recycling of mother liquor, and low solubility, and achieve The production process is safe and controllable, reduces energy consumption, and has good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

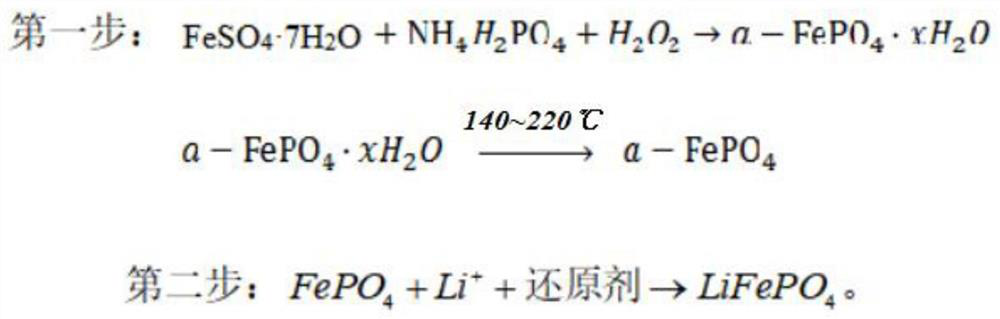

[0044] Such as figure 1 As shown, a low-cost method for preparing lithium iron phosphate cathode material in this embodiment includes the following steps:

[0045] (1) Preparation of iron phosphate

[0046] (a) 2mol of FeSO 4 ·7H 2 O and 2 mol of NH 4 h 2 PO 4 Dissolve in distilled water after mixing, slowly add H to the resulting mixture dropwise while stirring. 2o 2 , until H 2 o 2 The addition amount of is 1.1mol, produces a large amount of white precipitates in the solution. After the dropwise addition, a reaction precursor is obtained.

[0047] (b) Introduce the reaction precursor obtained in step (a) into a spray dryer, spray-dry at a feed rate of 1 mL / min, and a drying chamber temperature of 160 ° C, and finally collect the resulting light yellow powder, That is the iron phosphate (FePO 4 )Material.

[0048] (2) Preparation of lithium iron phosphate

[0049] (1) Weigh 99g (1.5mol) of lithium acetate and place it in a stirring device, add 400mL of distilled...

Embodiment 2

[0056] A method for preparing a lithium iron phosphate cathode material at low cost in this embodiment comprises the following steps:

[0057] (1) Preparation of iron phosphate

[0058] (a) 4mol of FeSO 4 ·7H 2 O and 4 mol of NH 4 h 2 PO 4 Dissolve in distilled water after mixing, slowly add H to the resulting mixture dropwise while stirring. 2 o 2 , until H 2 o 2 The addition amount of is 2.2mol, produces a large amount of white precipitates in the solution. After the dropwise addition, a reaction precursor is obtained.

[0059] (b) Introduce the reaction precursor obtained in step (a) into a spray dryer, spray dry at a feed rate of 5mL / min, and a drying chamber temperature of 140°C, and finally collect the resulting light yellow powder, That is the iron phosphate (FePO 4 )Material.

[0060] (2) Preparation of lithium iron phosphate

[0061] (1) Weigh 63.59g (1.5mol) of lithium chloride and place it in a storage tank with stirring function, add 150mL of distilled...

Embodiment 3

[0064] A method for preparing a lithium iron phosphate cathode material at low cost in this embodiment comprises the following steps:

[0065] (1) Preparation of iron phosphate

[0066] (a) 3mol of FeSO 4 ·7H 2 O and 3 mol of NH 4 h 2 PO 4 Dissolve in distilled water after mixing, slowly add H to the resulting mixture dropwise while stirring. 2 o 2 , until H 2 o 2 with FeSO 4 ·7H 2 The molar ratio of O was 1.65:3, and a large amount of white precipitates were produced in the solution. After the dropwise addition, a reaction precursor is obtained.

[0067] (b) Introduce the reaction precursor obtained in step (a) into a spray dryer, spray dry at a feed rate of 10mL / min, and a drying chamber temperature of 200°C, and finally collect the resulting light yellow powder, That is the iron phosphate (FePO 4 )Material.

[0068] (2) Preparation of lithium iron phosphate

[0069] (1) Weigh 155.9g (1.5mol) of lithium dihydrogen phosphate and place it in a stirring device, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com