3D printing technology-based coloring device and coloring method of photovoltaic piece

A 3D printing and photovoltaic technology, applied in photovoltaic power generation, injection devices, electrical components, etc., can solve the problems of increasing welding difficulty, affecting the photoelectric conversion efficiency of photovoltaic modules, and prone to false welding, so as to reduce welding requirements and reduce research and development costs. investment and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

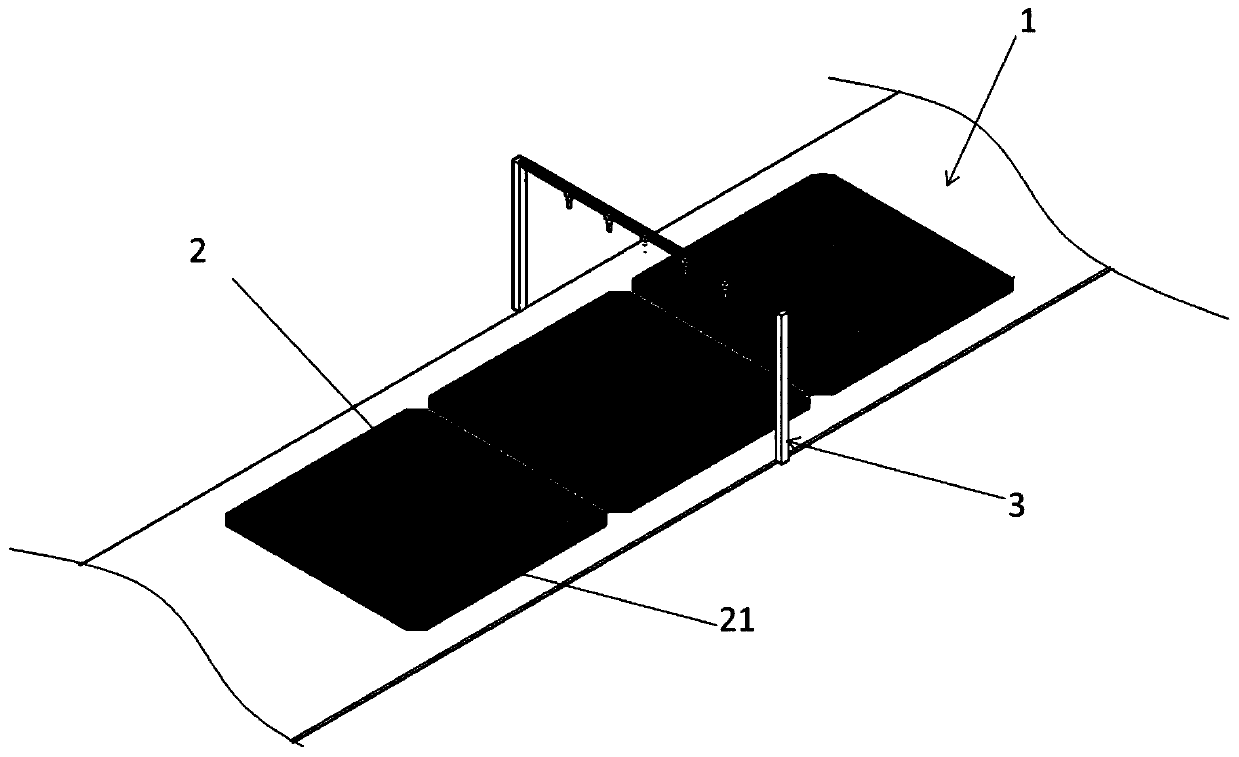

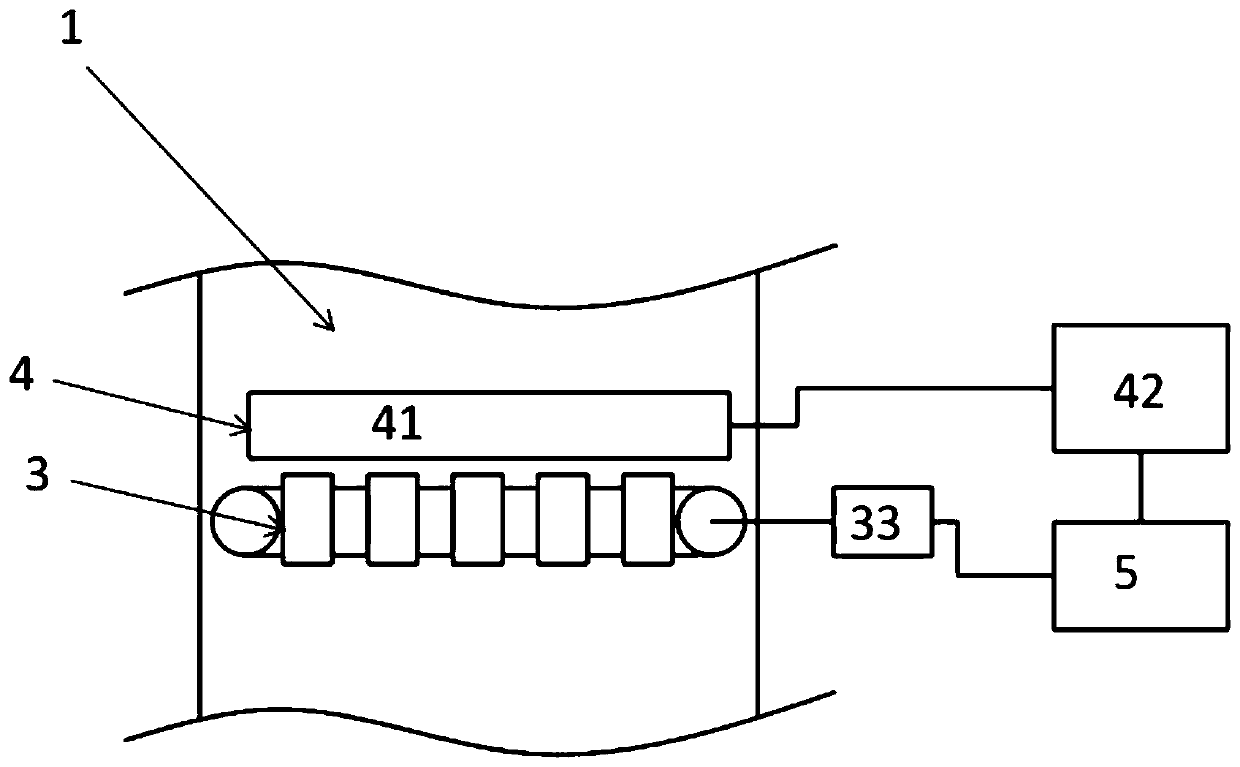

[0040] Such as figure 1 and figure 2 As shown, a photovoltaic sheet coloring device based on 3D printing technology includes a transmission line, an identification component, a printing component and a controller are arranged on the transmission line, and the printing component includes a lifting frame and a setting on the transmission line. On the nozzle on the lifting frame, the identification component includes a CCD image sensor and a processor. The CCD image sensor takes pictures of the photovoltaic sheets on the transmission line, and the processor identifies the position of the welding ribbon on the photovoltaic sheet and transmits the position signal to the controller. The controller controls the nozzle to adjust the position of the nozzle on the sliding rod. In this solution, the photovoltaic sheet is a battery assembly connected by a ribbon. bring.

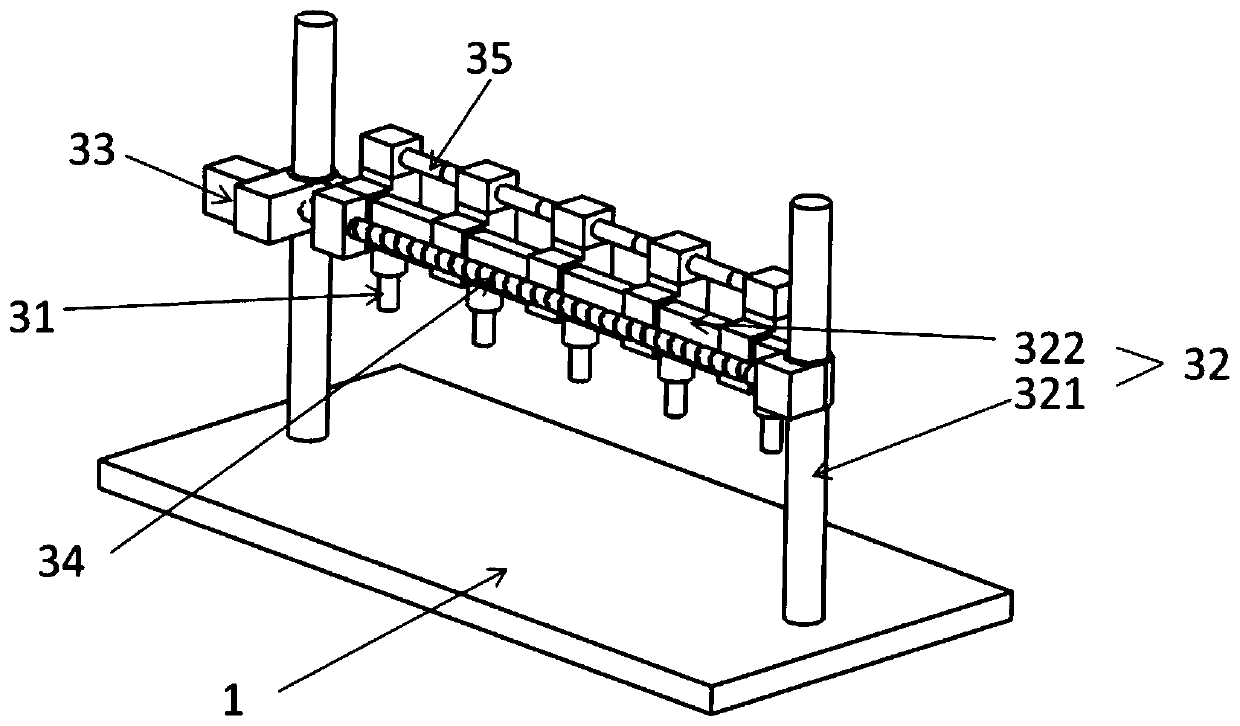

[0041] combine image 3 , Figure 4 and Figure 5 As shown, the lifting frame includes a lifting rod vertically ...

Embodiment 2

[0044] A production line for photovoltaic sheets, the above-mentioned photovoltaic sheet coloring device is applied to welding equipment, and the above-mentioned transmission line can be a transmission device on the welding equipment.

Embodiment 3

[0046] Such as Figure 6Shown, a kind of coloring method of photovoltaic sheet comprises the following steps:

[0047] S1. Connect the cells in series to form a photovoltaic sheet through ribbon welding;

[0048] S2, the photovoltaic sheet enters the above-mentioned coloring device;

[0049] S3. The CCD image sensor takes pictures of the photovoltaic sheet, and the processor identifies the position of the solder ribbon on the photovoltaic sheet and transmits it to the controller;

[0050] S4. The controller controls and adjusts the position of the nozzle on the sliding rod so that the nozzle corresponds to the welding ribbon;

[0051] S5. The nozzles color the ribbons on the photovoltaic sheet;

[0052] S6, drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com