A locomotive module connection structure

A technology of module connection and locomotive, applied in the direction of locomotives, railway car bodies, railway car body parts, etc., can solve the problems of restricting the layout and size of equipment in the car, occupying the inner space of the locomotive, and difficult for operators to access, etc., so as to achieve easy maintenance and replacement, reduce occupancy, reduce maintenance difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

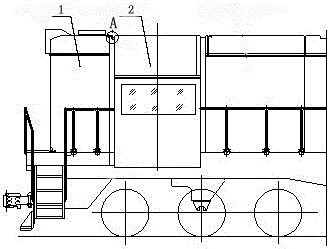

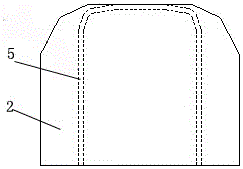

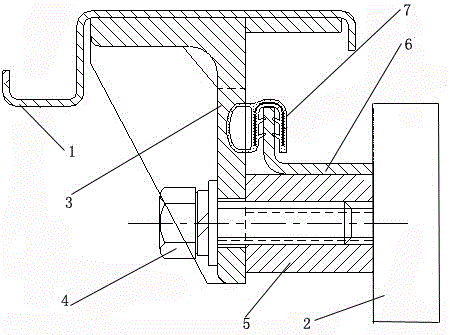

[0022] Such as Figure 4 As shown, a locomotive module connection structure includes a module one 1 and a module two 2, a module mounting beam 3 is arranged on the right end surface of the module one 1, a mounting seat 5 is arranged on the left end surface of the module two 2, and the module installation The beam 3 and the mounting seat 5 are both n-shaped and corresponding in size and position. The module mounting beam 3 is vertically connected to the module one 1 and its right end is bent at 90 degrees, and then it is close to the left end surface of the mounting seat 5, and the two are connected by several bolts 4. or fastened connection, the right end surface of the module one 1 is also provided with an n-shaped mounting plate 6 on the outer surface of the module mounting beam 3 corresponding to the n-shaped outer surface of the mounting seat 5, and a strip is arranged along the outer surface of the mounting seat 5 An n-shaped rubber strip slot 8 is correspondingly provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com