Liquid-holding flowing water cooling device and method

A technology of cooling device and cooling method, which is applied in the direction of lighting and heating equipment, heat exchange equipment, tubular elements, etc., and can solve the problem of high sealing requirements for heat exchange tubes and equipment arrangement, influence on the operation of rear equipment, and inability to use coolers and other problems, to achieve the effect of small equipment operation weight, reduced welding and sealing requirements, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

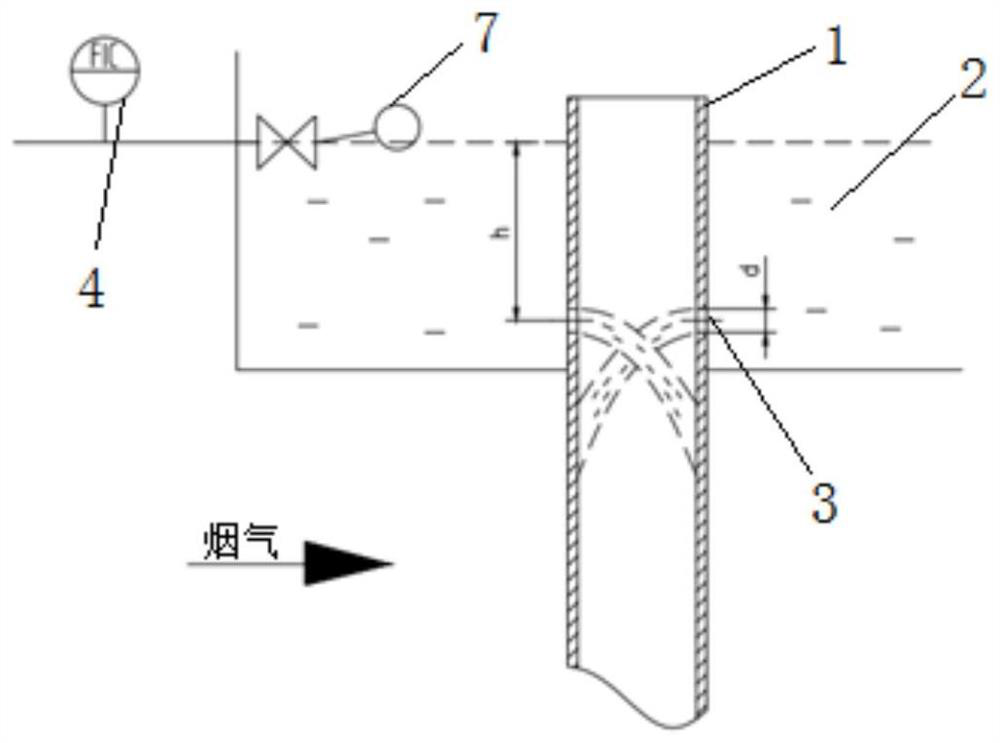

[0034] see figure 1 , Figure 3-4 , is a liquid-holding water cooling device, including more than one heat exchange tube 1 and a liquid-holding area 2 arranged on the upper periphery of the heat-exchange tube 1, and more than one heat-exchange tube 1 is provided with the liquid-holding area 2 is connected to the through hole 3, and the liquid holding area 2 is connected to the water pump through the pipeline.

[0035] In this embodiment, the liquid holding area 2 is an open environment, and the system can be in a dynamic equilibrium state at normal pressure through the cooperation of the liquid level detection device and the flow control valve. The water on the inner wall of the heat exchange tube 1 is in a state of natural flow, even if the heat exchange tube A small damage to the wall will not affect the operation of the entire equipment, reducing welding and sealing requirements, and normal pressure operation can make the equipment have a longer service life.

[0036] In ...

specific Embodiment 2

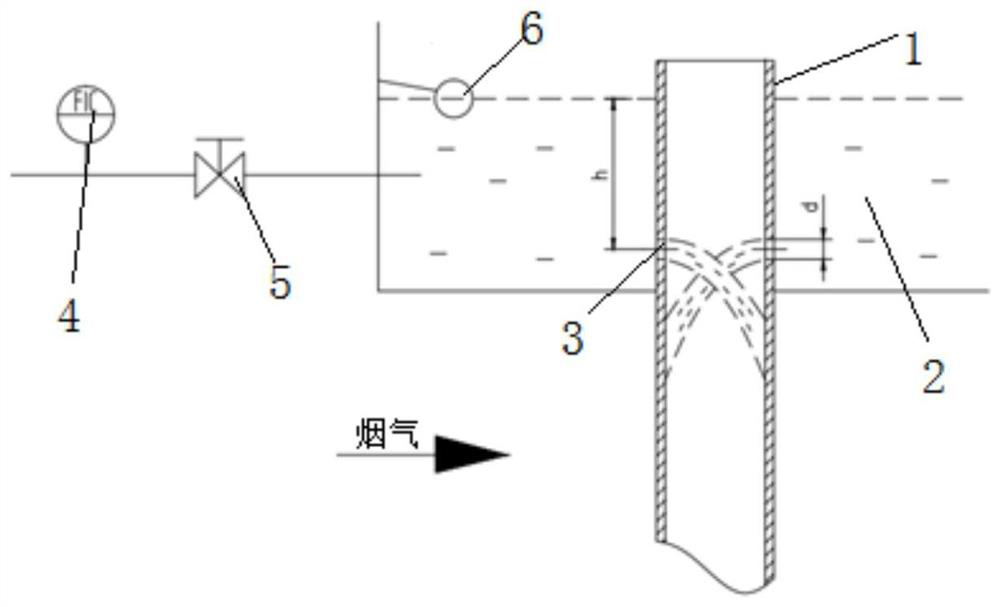

[0047] see figure 2 , Figure 3-4, the difference from the specific embodiment 1 is that in this embodiment, a liquid level gauge 6 is arranged in the liquid holding area 2, and a flow meter 4 and a water inlet valve 5 are arranged on the pipeline connected to the water pump. In step S2, according to Pipe flow or liquid level height adjusts the opening of water inlet valve 5, thereby controlling the height of the liquid level in the liquid holding area 2.

[0048] The flue gas of the present invention passes outside the pipe, and the cooling water flows naturally from top to bottom along the inner wall of the heat exchange pipe 1 through the through hole 3 on the heat exchange pipe 1 to take away heat. Effectively reduce the weight of water in the entire operating system, making the weight of the entire equipment smaller; the entire system is in a state of normal pressure, even if there is a small damage to the wall of the heat exchange tube 1, it will not affect the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com