Gas electron multiplier, gas photomultiplier and gas X ray image intensifier

A gas electron multiplication and X-ray technology, which is applied to the detailed information of electron multipliers, dynodes, electrode devices of multiple dynodes, etc. It can solve the problems of high height and complex structure, so as to solve the problems of being easily damaged by ion feedback, improve the gain stability, and improve the overall gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

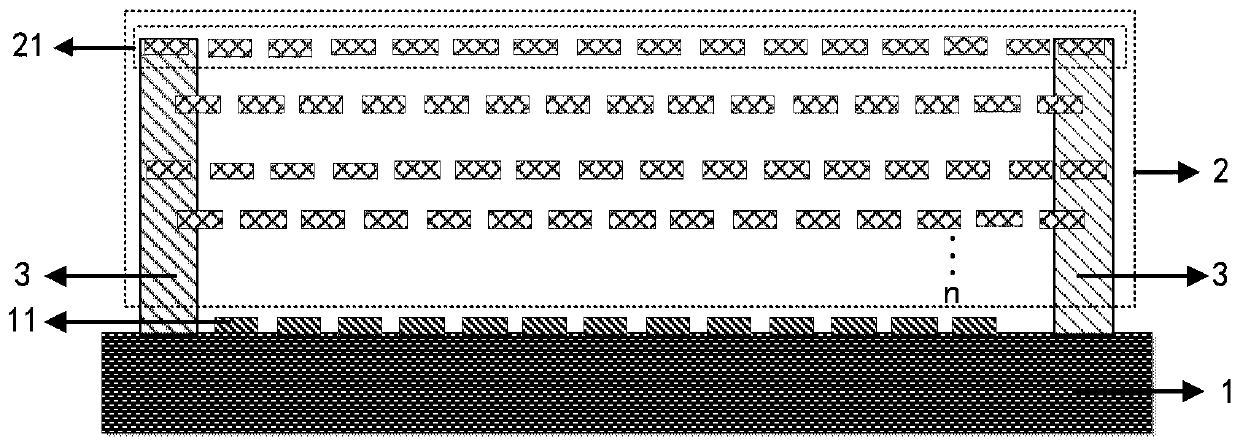

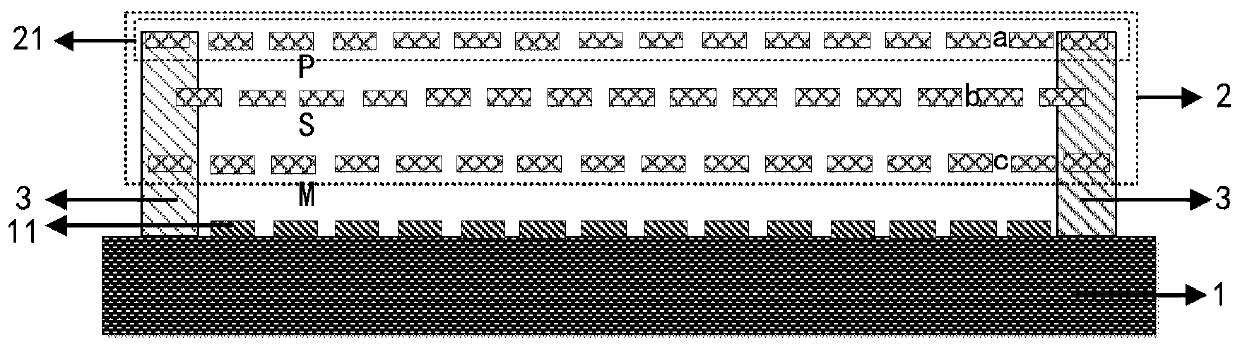

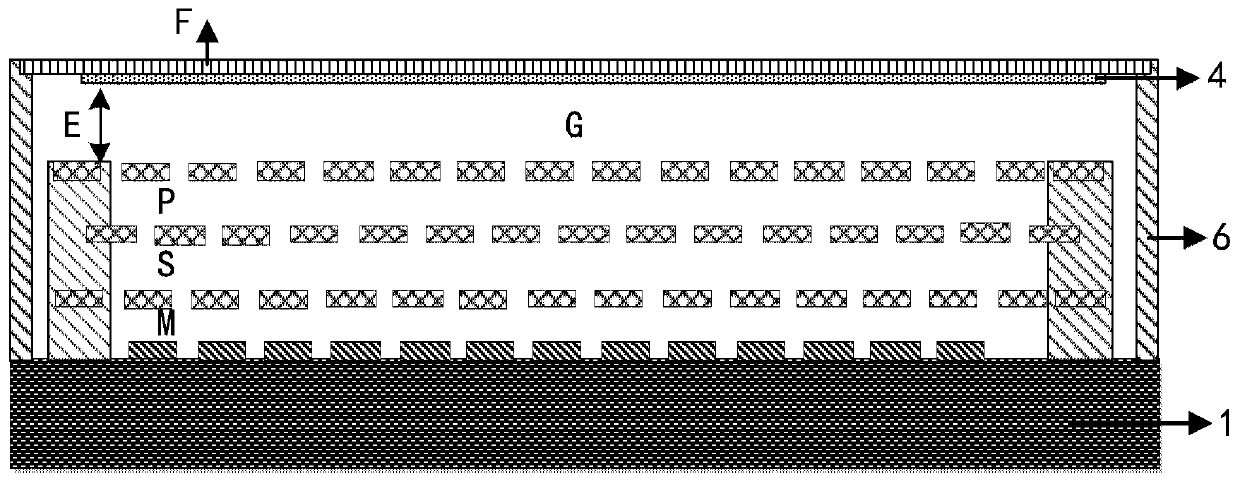

[0040] figure 1 Schematically shows the structure diagram of the gas electron multiplier provided by the embodiment of the present invention, as figure 1 As shown, it includes: a readout anode plate 1 . The micro-grid electrode structure 2 is formed by cascading n layers of micro-grid electrodes 21 through a support structure 3 fixed on the readout anode plate 1 . Wherein, the micropores of the upper layer of micro-grid electrodes 21 are misaligned with the micro-pores of the lower layer of micro-grid electrodes 21, and a gas avalanche amplification zone is formed between the micro-grid electrodes 21, and n is an integer greater than or equal to 3.

[0041] Wherein, the thickness of the micro-grid electrode 21 may be, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com