Flexible transparent conductive film and preparation technology thereof

A technology of transparent conductive film and preparation process, which is applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., and can solve the limitations of the application in the field of flexible electronics and the complexity of photolithography technology , high resistance of the conductive film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

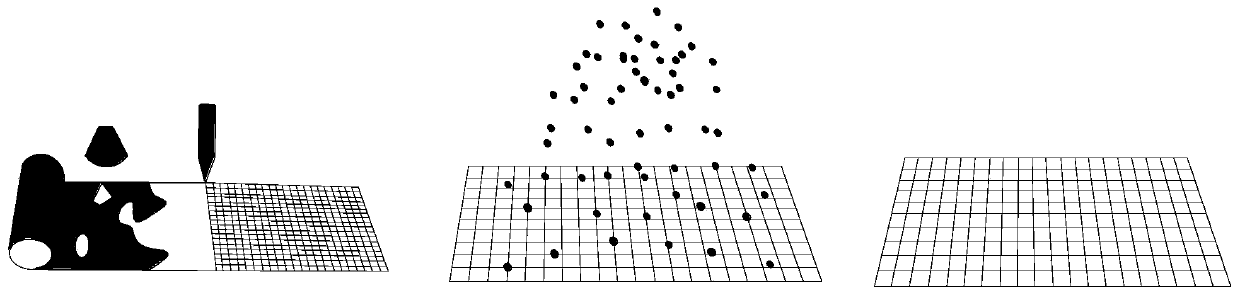

[0059] The first embodiment of the present invention provides a preparation process of a flexible transparent conductive film, and the specific steps of the preparation process include:

[0060] (1) Cut a polyethylene terephthalate (PET) film (light transmittance ~ 95%) with a thickness of 100 μm into a rectangular piece of 50cm*60cm, wash it with deionized water and absolute ethanol for 30min, respectively, Dry and use as a base. Prepare TiO with a concentration of 5% 2 weak. TiO with a thickness of 1 μm was sprayed 2 The colloidal layer is evenly coated on the surface of the PET substrate;

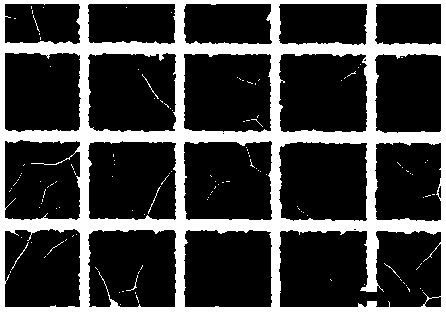

[0061] (2) Place the colloidal film in step (1) at an air pressure of 1*10 -3 Pa, the humidity is 40%, and the temperature is 55°C and dried to make it evenly cracked;

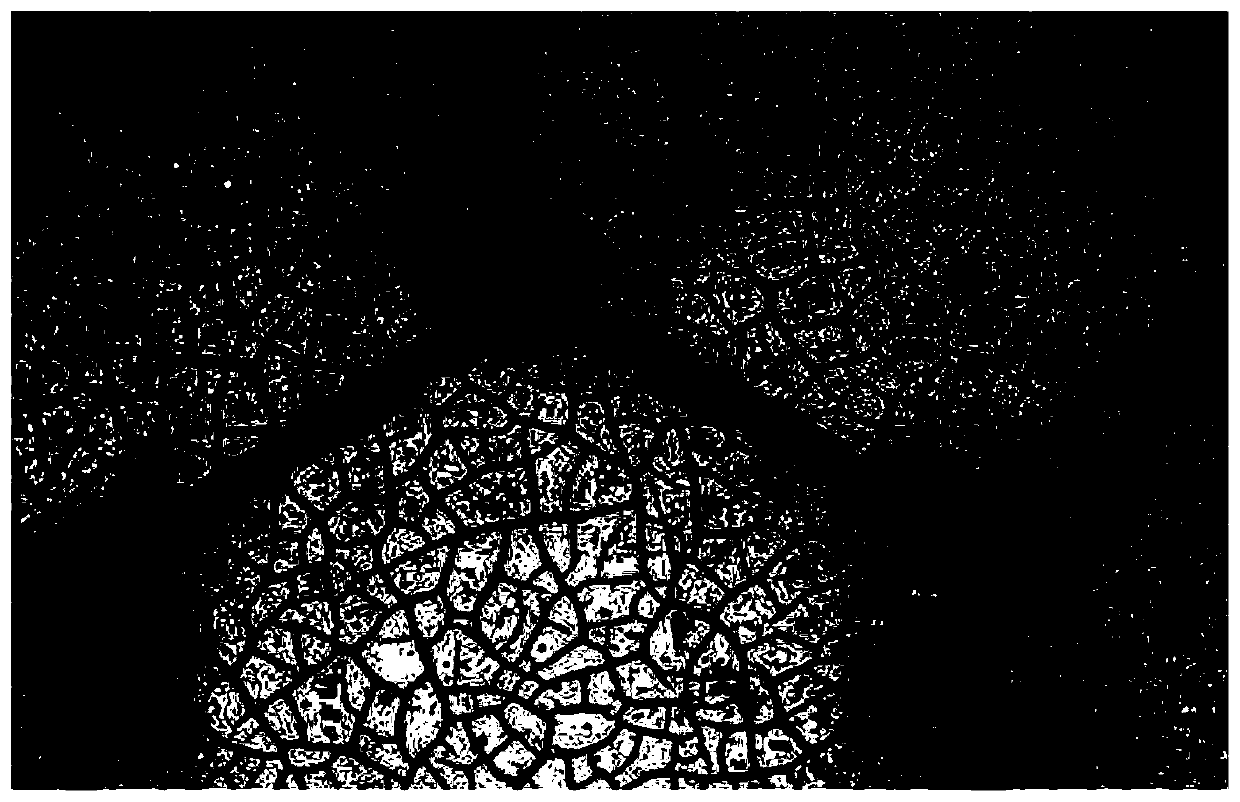

[0062] (3) Then the grid is processed on the colloidal template by laser cutting colloidal film technology, and the shape of the grid is controlled by the computer as a triangular grid such as Figure 4 As shown in...

Embodiment 2

[0066] The steps of the second embodiment are roughly the same as those of the first embodiment. The difference is that in this embodiment, in step (3), the grid is processed on the colloidal template by laser cutting colloidal film technology, and the grid shape is a rectangular network. grid, such as Figure 4 (b) shown.

[0067] Embodiment 2 of the present invention provides the same implementation principles and technical effects as Embodiment 1. For brief description, for details not mentioned in this embodiment, reference may be made to the corresponding content in Embodiment 1.

Embodiment 3

[0069] The steps of the third embodiment are roughly the same as those of the first embodiment. One of the differences is that in this embodiment, in step (3), the grid is processed on the colloidal template by laser cutting colloidal film technology, and the grid shape is A hexagonal grid such as Figure 4 As shown in (c), the second difference is that in step (5), the film is immersed in absolute ethanol to remove the colloid, and dried to obtain a flexible transparent conductive film.

[0070] Embodiment 3 of the present invention provides the same implementation principles and technical effects as Embodiment 1. For brief description, for details not mentioned in this embodiment, reference may be made to the corresponding content in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com