A Control Strategy for Hot Surface Igniters

A control strategy, igniter technology, applied in the direction of using spark ignition, controlled combustion, incandescent ignition, etc., can solve the problems of shortening the life of the hot surface igniter, increasing, damage to the power supply cost, etc., to improve competitiveness and application. Scope, effect of applying cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0073] Example 1: Application on household or commercial gas stoves and water heaters

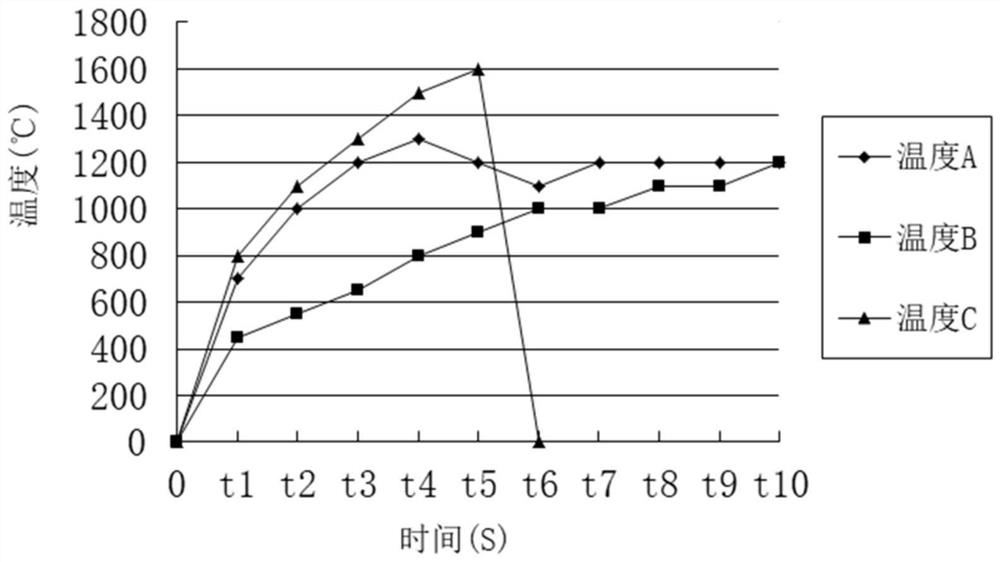

[0074] When the gas cooker or water heater is in use, the time between ignition and successful ignition will arouse people's anxiety if it takes too long, and it is generally best to control it within 5 seconds.

[0075] However, in applications where there is no time requirement, in order to ensure that the hot surface igniter does not have a moderate service life, we generally use a constant voltage or constant power control method to make the igniter heat up slowly.

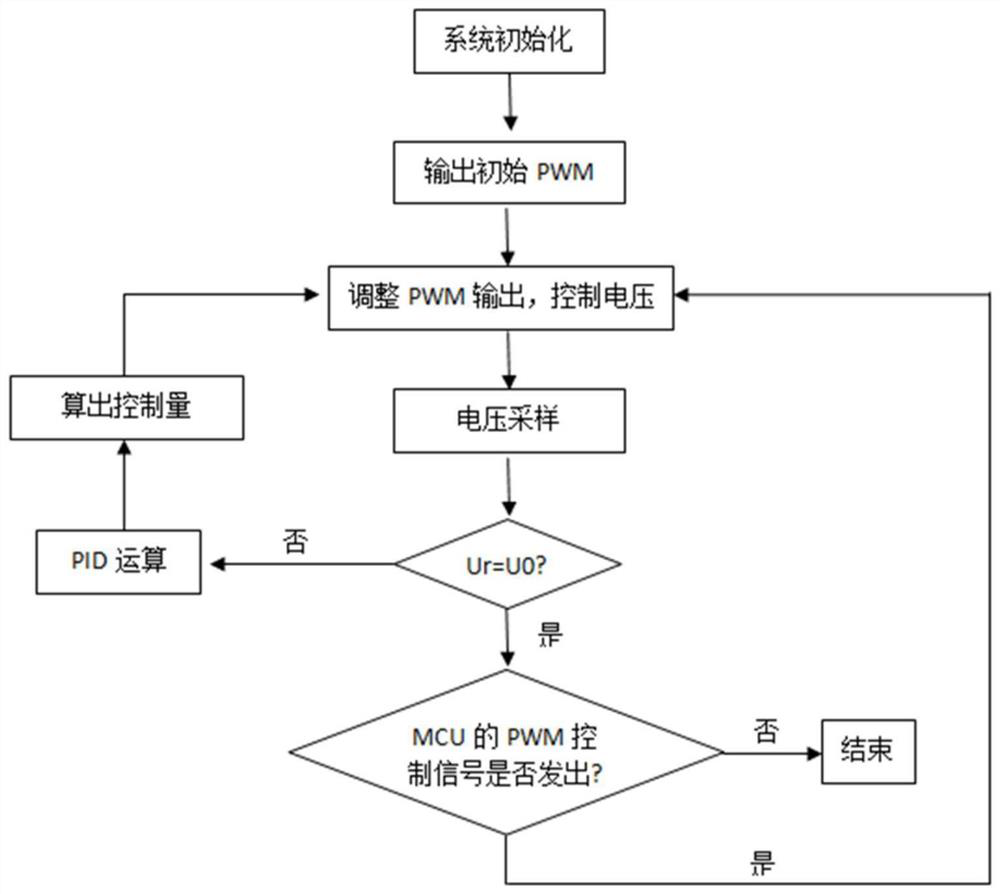

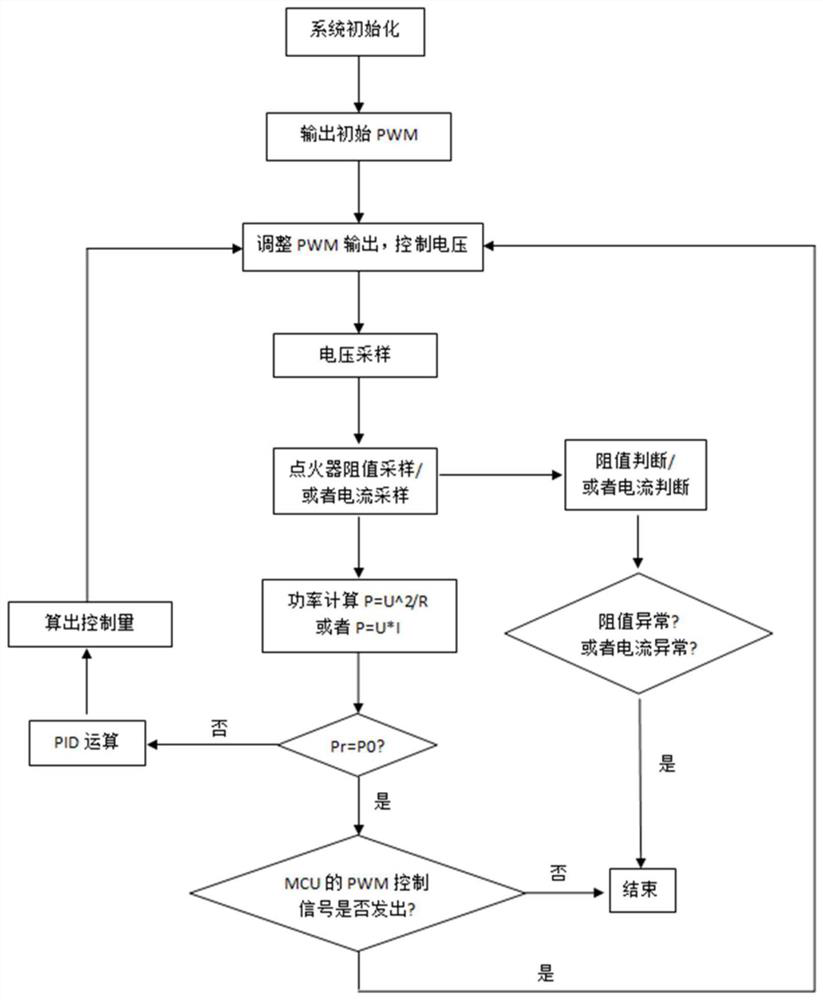

[0076] Combining the above, if you want the hot surface igniter to be well applied on the gas cooker or water heater, you must balance the two contradictions. Therefore, the three types of control strategies of variable voltage control, variable power control, and variable voltage plus variable power hybrid control in this embodiment can be used to ensure the service life of the hot surface igniter and shorten the ignition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com