Paving device for highway base layer stabilized soil

A technology for laying devices and road bases, applied in roads, roads, road repairs, etc., can solve problems such as segregation, and achieve the effects of avoiding pollution, saving resources, and ensuring structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

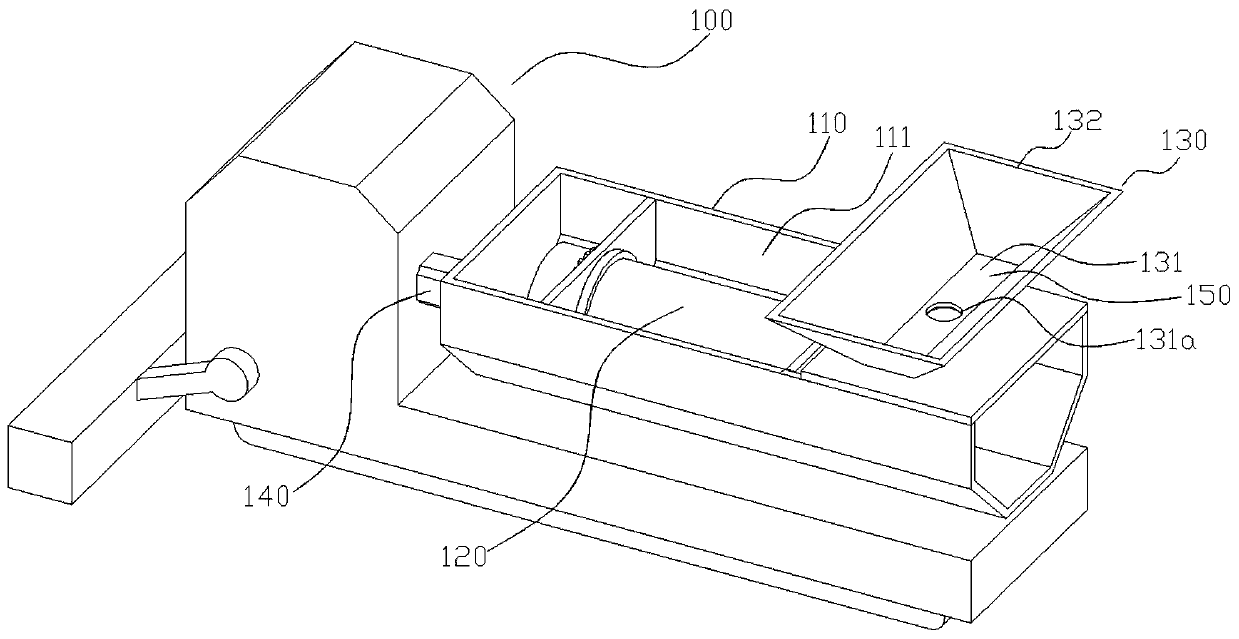

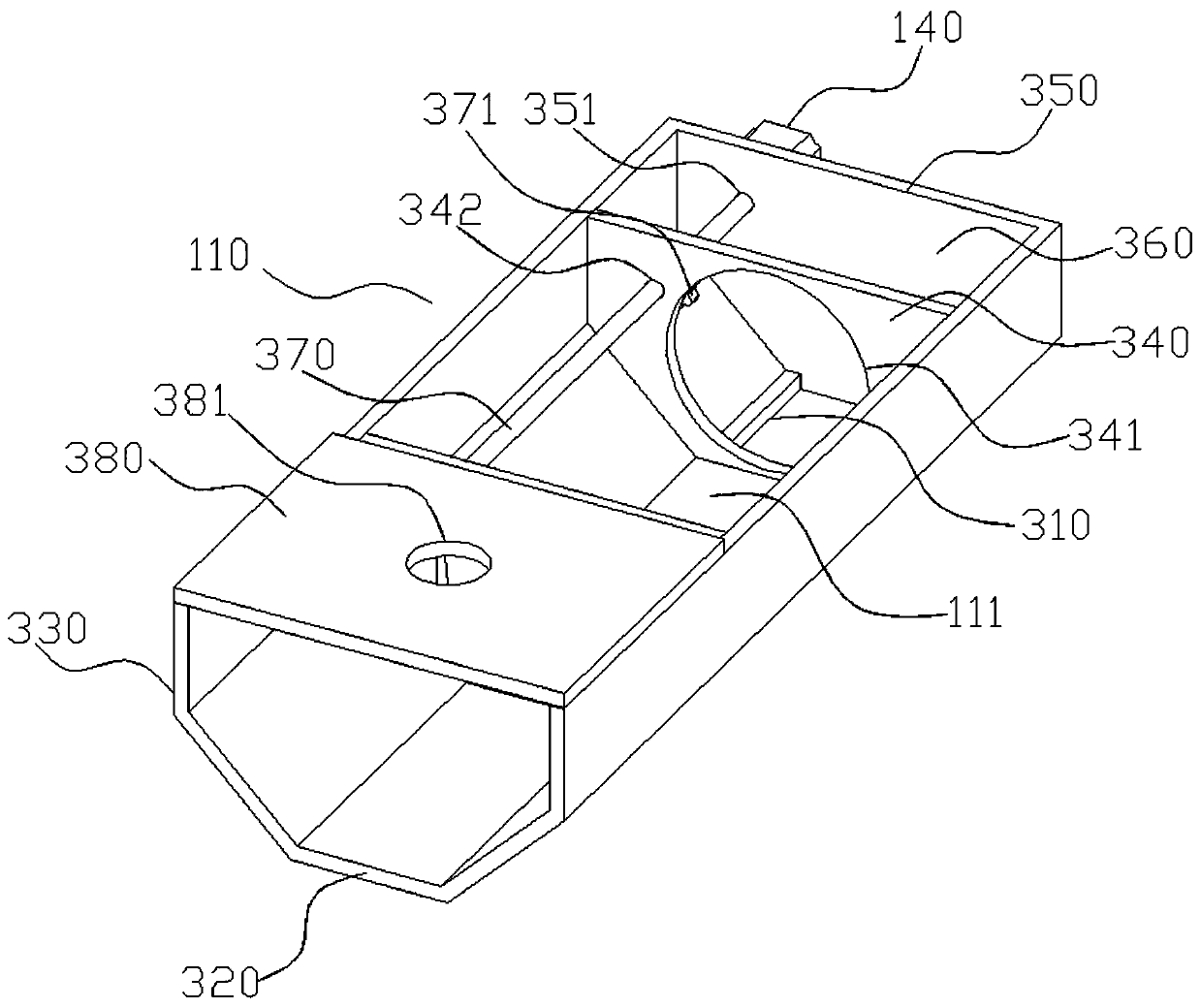

[0038] Such as Figure 1-8 As shown, the present embodiment provides a paving device for road base stabilized soil, which includes a paver body 100, which is provided with a paver hopper 110, and a roller installation Cavity 111, the drum installation cavity 111 is provided with a rotatable drum 120, and the inner wall of the drum 120 is provided with a spiral blade 510; a material conveyor belt 210 is provided below the paver hopper 110, and the paver hopper 110 is close to the material conveyor belt 210 The end of the drum 120 is provided with a material delivery port 310, and the side wall close to the material delivery port 310 is provided with a discharge port 520 on the drum 120. Mouth 411 is the through hole that the cross section is circular, and the end portion near feed inlet 411 is provided with feed hopper 130 on the paver hopper 110, and the bottom end of feed hopper 130 is provided with feed pipe 710, and feed pipe 710 The end of the cylinder passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com