Glass kiln arch top repair auxiliary device

A glass furnace and auxiliary device technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easy melting, slow cooling of hot feed, dripping, etc., to achieve overall structural stability and improve speed. , the effect of easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

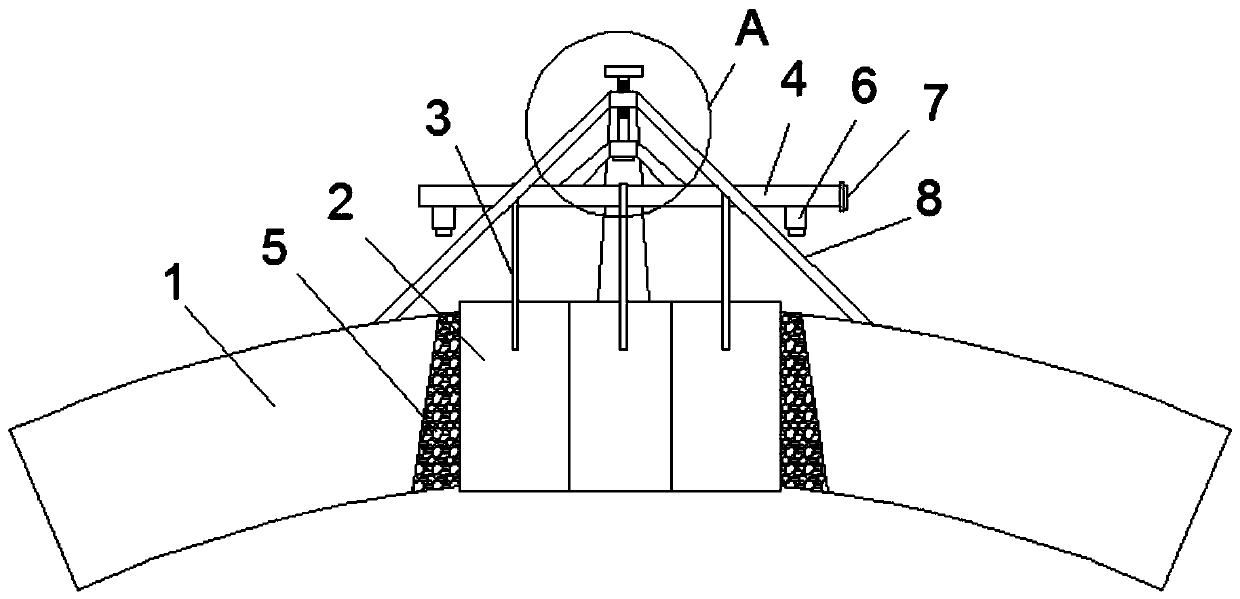

[0021] see Figure 1-2 , an auxiliary device for repairing the roof of a glass kiln, including a hanging pipe 4 for hanging silica bricks 2, and the silicon bricks 2 are hung on the hanging pipe 4 through a prefabricated hanging rod 3 connected thereto; the hanging pipe 4 One end is sealed, and the other end of the hanging pipe 4 communicates with the external gas supply pipeline through the connector 7; the lower end of the hanging pipe 4 is provided with a plurality of nozzles 6, and the spraying direction of the nozzles 6 is directly facing the dome 1 and the silica brick 2 The repair material 5 between them; the hanging pipe 5 is placed on the outer surface of the dome 1 through a tripod 8, and the upper end of the tripod 8 is fixedly connected with the hanging pipe 4 through a connecting rod 14.

[0022] The working principle of the present invention is: the method for realizing the repair of the light transmission hole of the dome 1 by the present application comprises t...

Embodiment 2

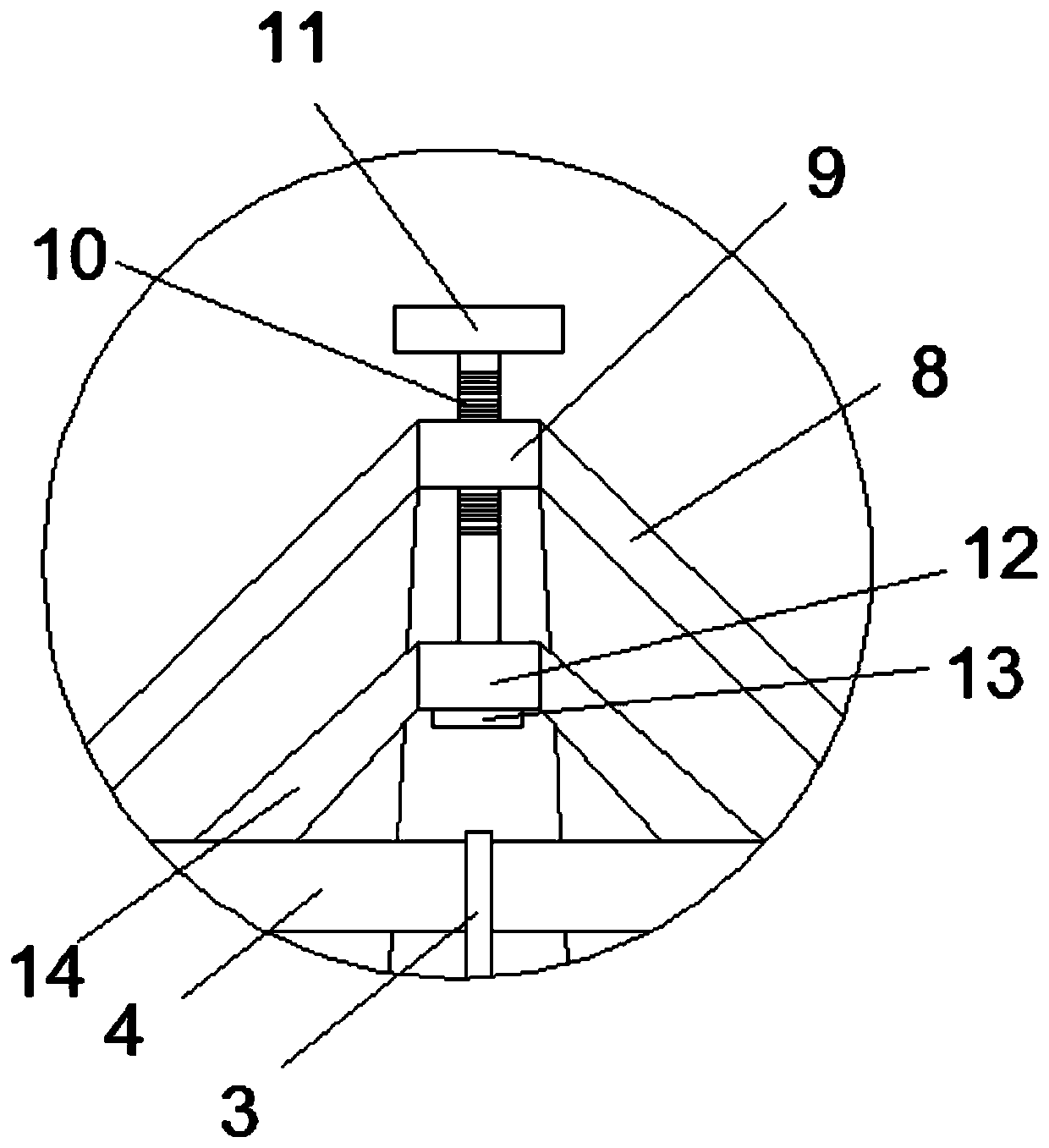

[0028] see Figure 1-2 , the same as Embodiment 1, the difference is that a height adjustment device is added, and the height adjustment device includes a first sleeve 9 fixed on the upper end of the tripod 8 and a second sleeve 12 on the upper end of the connecting rod 14, the first A threaded screw 10 is provided inside the sleeve 9 , the screw 10 passes through the second sleeve 12 and extends below the second sleeve 12 to connect with the stopper 13 , and a rotary handle 11 is provided at the upper end of the screw 10 .

[0029] Through the setting of the height adjustment device, on the one hand, the installation height of the silica brick 2 can be adjusted to match the height of the dome 1; Pressing down on the tripod 8 under action makes the overall structure stable.

[0030] Preferably, the lower ends of the three legs of the tripod 8 are all provided with fixing blocks (not shown), so as to further improve its overall stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com