Steel rail surface alloy layer welding method and its material

A technology of surface welding and alloy layer, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of low production efficiency, large rail damage, low bonding strength of corrosion-resistant alloy layer, etc., and achieve low rail deformation and welding stress. , good conductivity, easy to automate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

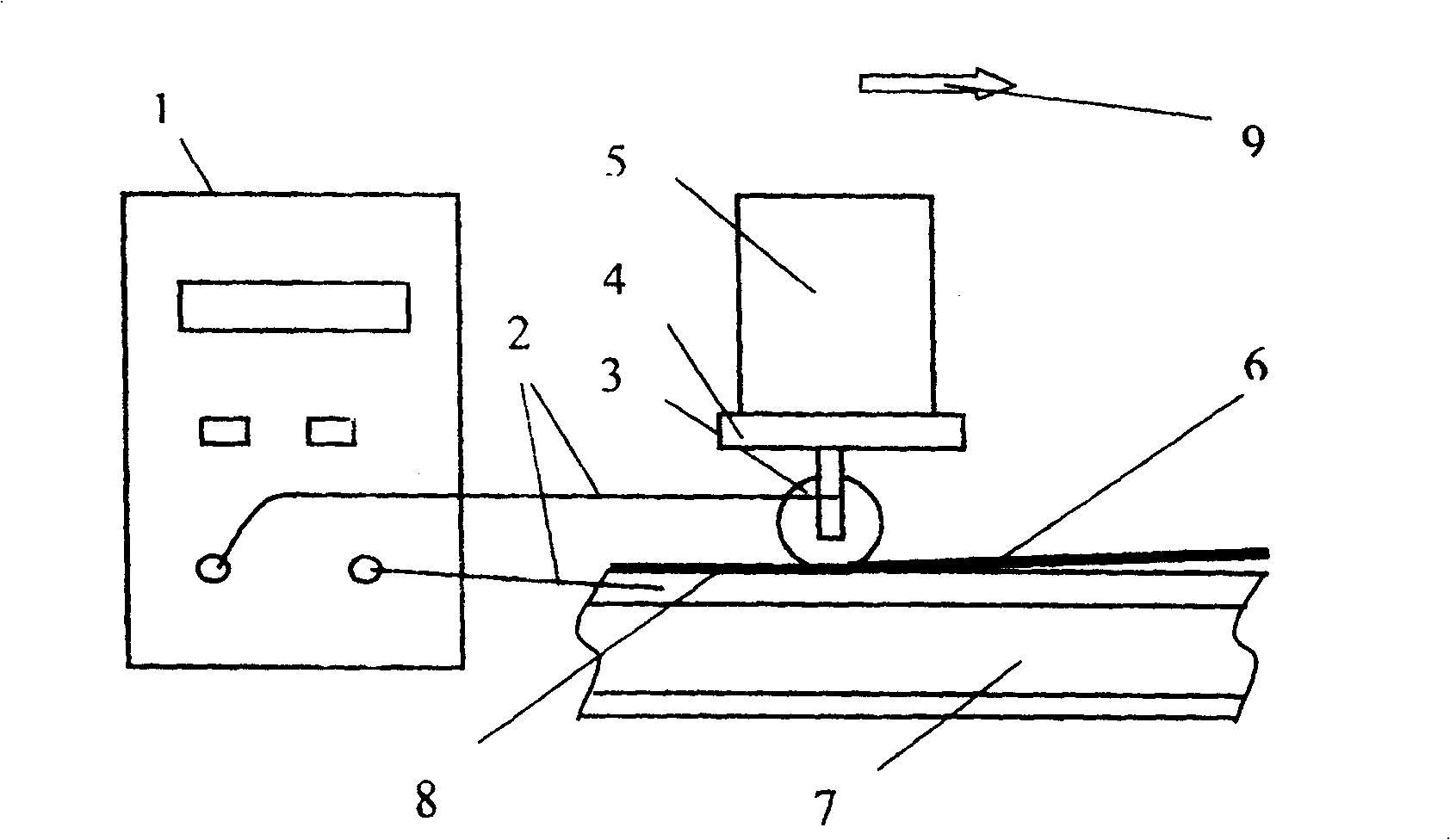

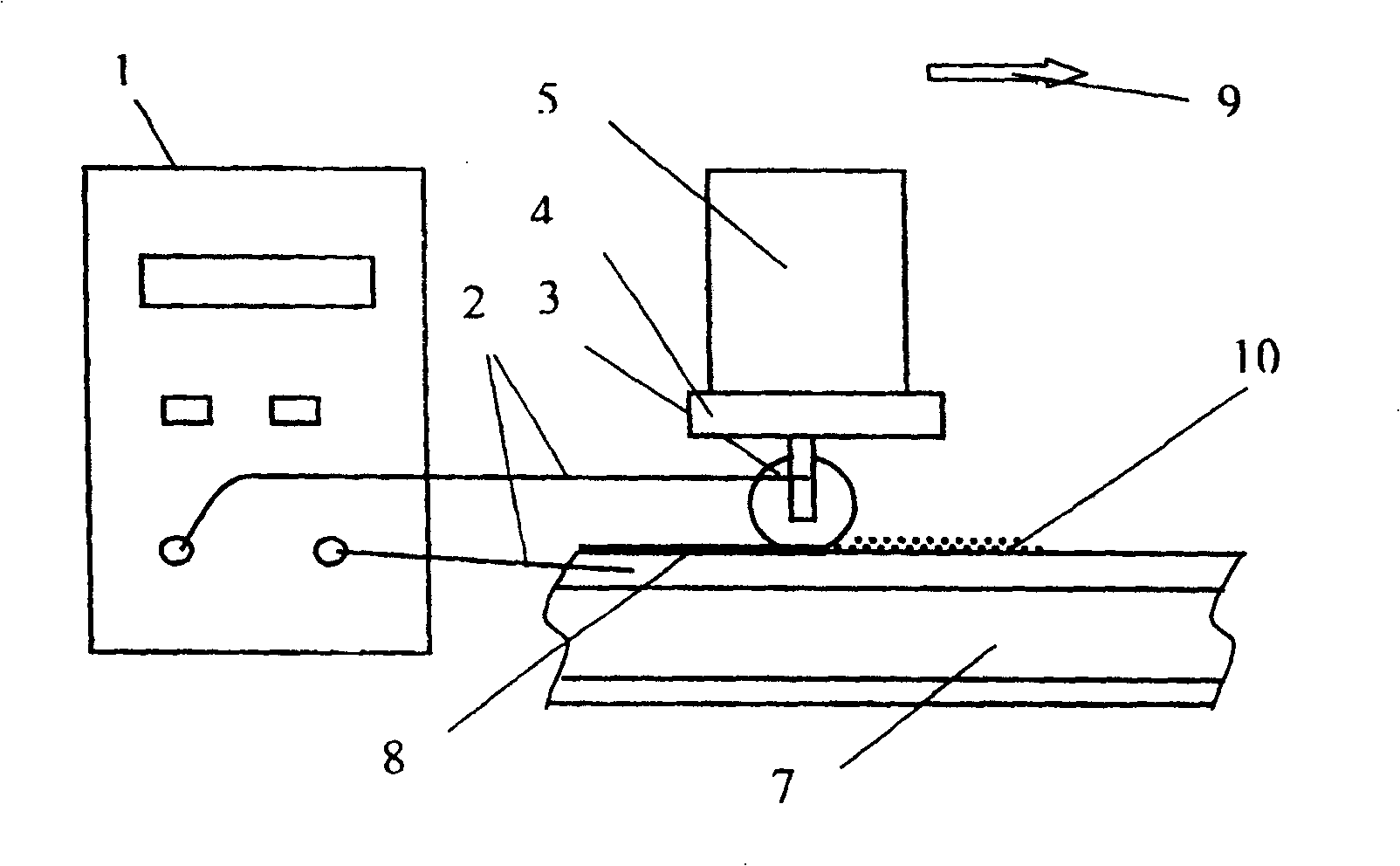

[0052] Embodiment: the surface of the rail adopts NiCrBSiCu self-fluxing alloy powder to carry out resistance rolling welding alloy powder powder rolling welding device see figure 2 , the composition of the self-fluxing alloy powder is Cu10%, C0.35%, B2.4%, Si2.5%, Cr6.5%, Fe6.3%, the remainder of Ni, and the powder particle size is -300 mesh to +800 mesh , the rails used are the same as those in the comparative example.

[0053] The welding process is as follows: Use an emery cloth wheel to grind the surface of the rail to be welded and the ground wire to expose the metallic luster, and then connect the ground wire of the resistance welding pulse power supply to the rail tightly; use absolute alcohol to mix the NiCrBSiCu special alloy powder into a paste shape, and then use a brush to coat the paste powder on the fresh surface of the rail, the width of the powder layer is 3mm, and the thickness is 0.25-0.30mm; press the roller electrode 3 (width 5mm) on the self-fluxing allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com