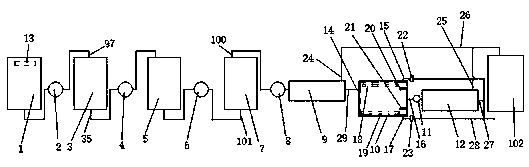

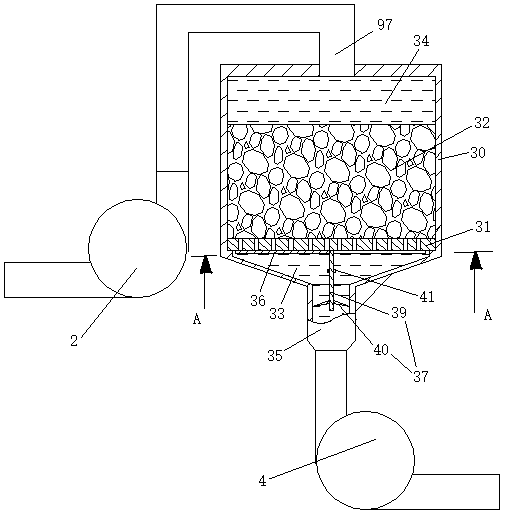

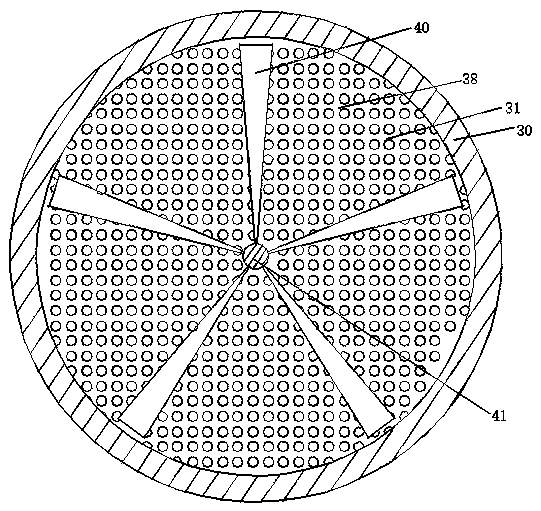

Ultrafiltration reverse-osmosis water purification treatment system

A water purification and reverse osmosis technology, applied in filtration treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of poor water flow of sand filter, difficult to form fixed flow channels, and large site area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] The difference between embodiment two and embodiment one is:

[0062] see Figure 9 , the bracket is also provided with an arc-shaped avoidance groove 96 for the insertion of the vertical latch with the second horizontal hinge axis as the centerline. When the baffle frame rotates with the second horizontal hinge until the dial frame pushes the object supported on the bracket into contact with the trigger plate, the vertical pin is aligned with the arc-shaped avoidance groove, thereby preventing the reverse osmosis filter from being transferred to the holder through the baffle frame. Damage to the trigger plate, horizontal drive rod and vertical latch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com