Manual assembly line layout for automobile tires

A technology for automobile tires and assembly lines, which is applied in the direction of wheel assembly equipment, wheels, and vehicle parts. It can solve problems such as large footprint, low production efficiency, and safety, and achieve reduction in the number of forklifts, increase production efficiency, and reduce motion waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

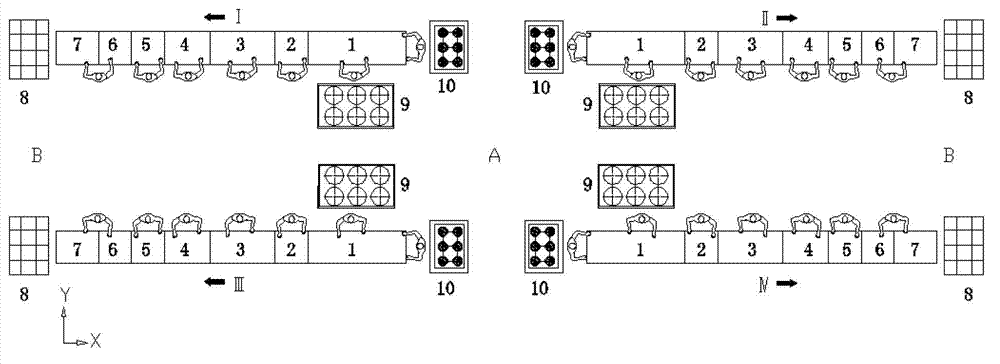

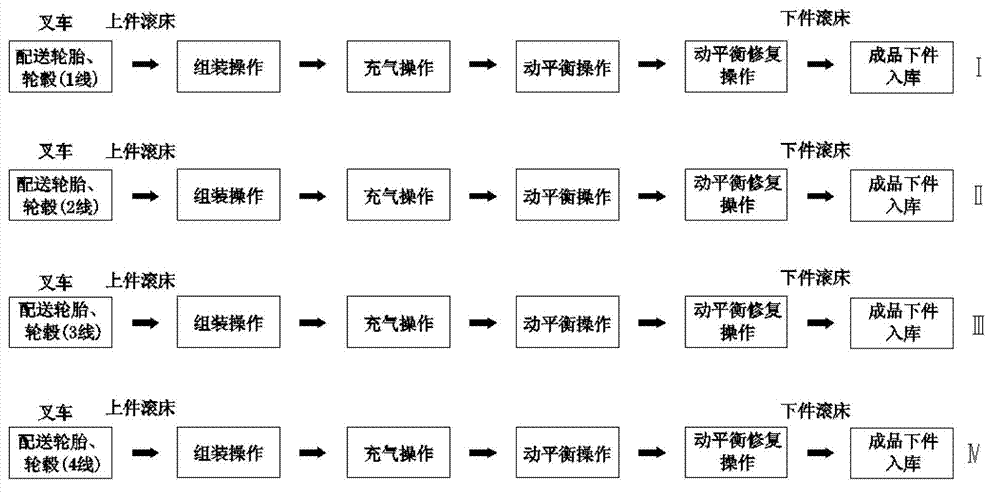

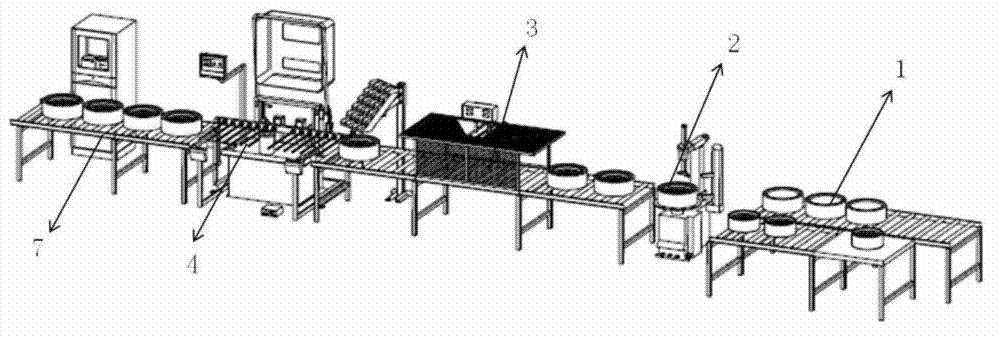

[0038] see Figure 4 As shown, the embodiment of the present invention provides a layout of a manual assembly line for automobile tires, which at least includes an upper roller bed 1, a disassembly machine 2, an inflator 3, a balancing machine 4, a correction roller bed 5, a correction platform 6, and a lower roller bed. Equipment such as bed 7, workbench 19 for lower parts, and auxiliary station appliances such as wooden pallet rack 8, forklift 9, and semi-finished product storage place 10; the manual tire assembly line is composed of more than two assembly lines, and each single assembly line includes existing Equipment with tire manual assembly line: a dismantling machine 2, an inflator 3, a balancing machine with a lifting platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com