Rail electric flat carriage

An electric flat car and rail technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem of easy overturning of trolleys, reduce the risk of overturning, have a simple fixed structure, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

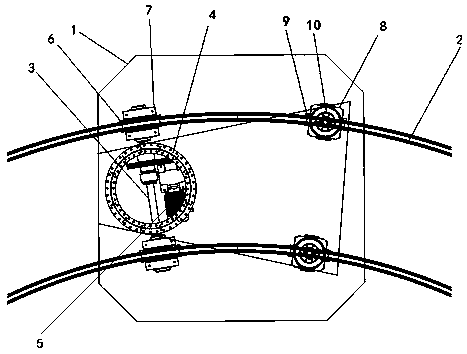

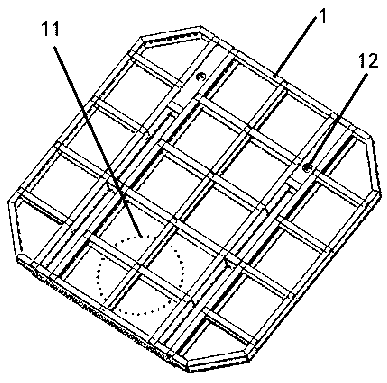

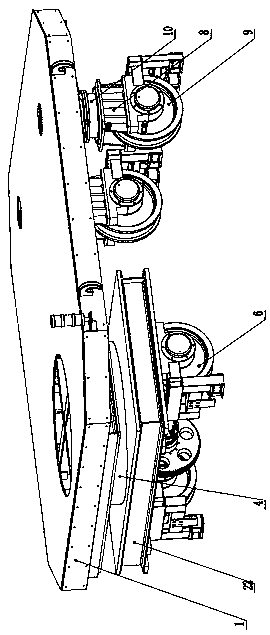

[0053] Such as Figure 1 to Figure 11 As shown, the rail electric flat car includes a car body frame 1, and the car body frame 1 is used to carry heavy objects. The rail electric flat car also includes a front drive axle 3, and the two ends of the front drive axle 3 are connected to two front wheels 6. The front drive axle 3 includes a differential 14 and half shafts connected with the two differential output shafts of the differential, and the two front wheels 6 are respectively fixed with the two half shafts, wherein the left half shaft 191 is connected with the differential output shafts. The shaft is fixed through the coupling 20, the right half shaft 192 and the differential output shaft are fixed through the adapter shaft tube 21, the right half shaft 192 and the adapter shaft tube 21 are fixed through the coupling 20, the differential output shaft and the rotary The shaft connecting tube is also fixed by a shaft coupling 20 . The transmission of the differential 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com