Preparation method of complex wood material

A wood material and complexing technology, which is applied in the field of preparation of complex wood materials, can solve problems such as cracking and deformation, lack of forest resources, decay and mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

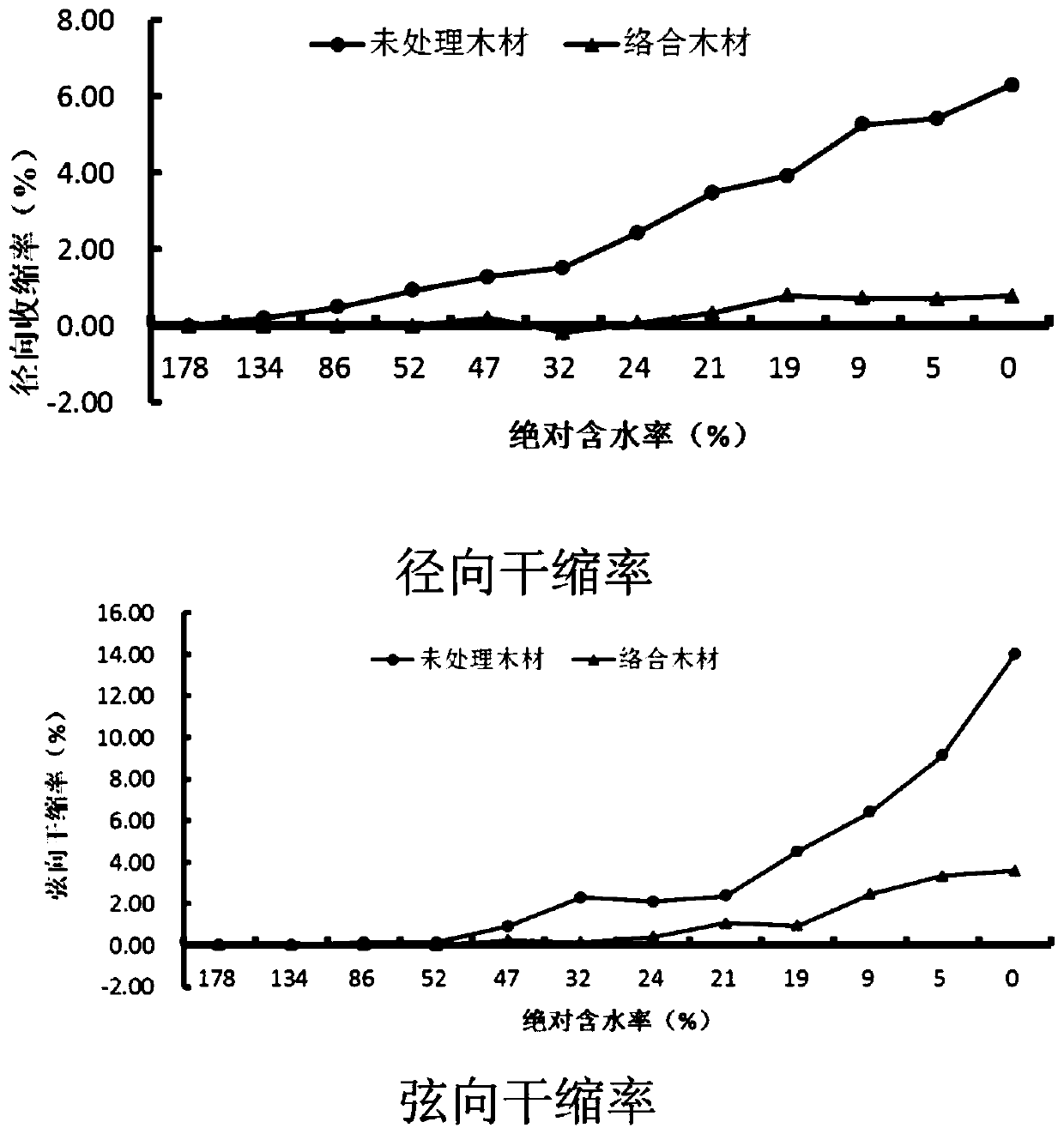

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of a complexed wood material, comprising:

[0036] Step 1: Prepare the right amount of logs

[0037] A fresh eucalyptus tree with a diameter of 25 cm and a mass ratio of 2.5% plant polyphenols is sawed and processed to grow into a 300 cm wood segment, and after removing the bark, a eucalyptus log is obtained, and the absolute moisture content of the wood is 68%;

[0038] Step 2: Introducing metal salts into the above-mentioned polyphenol logs

[0039] Dissolve ferrous sulfate in the aqueous solution, and after stirring evenly, obtain ferrous sulfate salt solution, the concentration is 3.0g / L;

[0040] The polyphenol log prepared in step 1 is soaked in the ferrous sulfate salt solution in step 2 by using the atmospheric pressure impregnation method, and the impregnation time is 60 days, and the temperature is room temperature to obtain the polyphenol metal salt log;

[0041] Step 3: Dry polyphenol metal salt logs

Embodiment 2

[0047] A method for preparing oak complex sawn timber, comprising:

[0048] Step 1: Oak sawn timber preparation

[0049] Cut the fresh oak wood with a diameter of 350mm and containing 1.2% plant polyphenols into a 1200mm section, remove the bark, and then saw and process it into a sawn timber with a width of 152mm, a thickness of 22mm, and a length of 1200mm , using the kiln drying method to dry it to an absolute moisture content of 30%;

[0050] Step 2: Introducing metal salts into the above-mentioned oak sawn timber

[0051] Dissolve aluminum sulfate in the aqueous solution and stir evenly to obtain aluminum sulfate solution with a concentration of 0.3g / L;

[0052] Soak the polyphenol oak sawn timber prepared in step 1 in the aluminum sulfate aqueous solution in step 2, adopt the hydraulic impregnation method, the impregnation pressure is 2.0MPa, the impregnation time is 48h, and the impregnation temperature is 25°C. When it is in the cell cavity, cell wall or intercellul...

Embodiment 3

[0058] A preparation method of red sandalwood (grass pear) complex sawn timber, comprising:

[0059] Step 1: Prepare an appropriate amount of bird's foot red sandalwood (grass pear) sawn timber

[0060] Cut fresh red sandalwood (grass pear) containing 2.4% of plant polyphenols into 300cm wood segments, sawing into sawn timber with an interface of 50mm×50mm, and controlling the absolute moisture content to 80%;

[0061] Step 2: Introduce zinc sulfate into the above-mentioned red sandalwood (grass pear) sawn timber

[0062] Dissolving zinc sulfate in the aqueous solution, after stirring evenly, obtains zinc sulfate solution with a concentration of 0.8g / L;

[0063] The sawn wood of red sandalwood (grass pear) prepared in step 1 is impregnated by hydraulic pressure, the impregnation time is 6h, the temperature is 25°C, the pressure is 1.2MPa, the impregnation amount of zinc sulfate aqueous solution is 110%, and the wood is taken out to form polyphenols zinc salt wood;

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com