Turbine tenon groove ultrasonic assistance precise electrolysis grinding method

A processing method and electrolytic grinding technology, which is applied in the field of electrolytic grinding, can solve problems such as unstable processing process and loss of tool grinding wheel, and achieve the effect of clear method principle, stable processing process and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

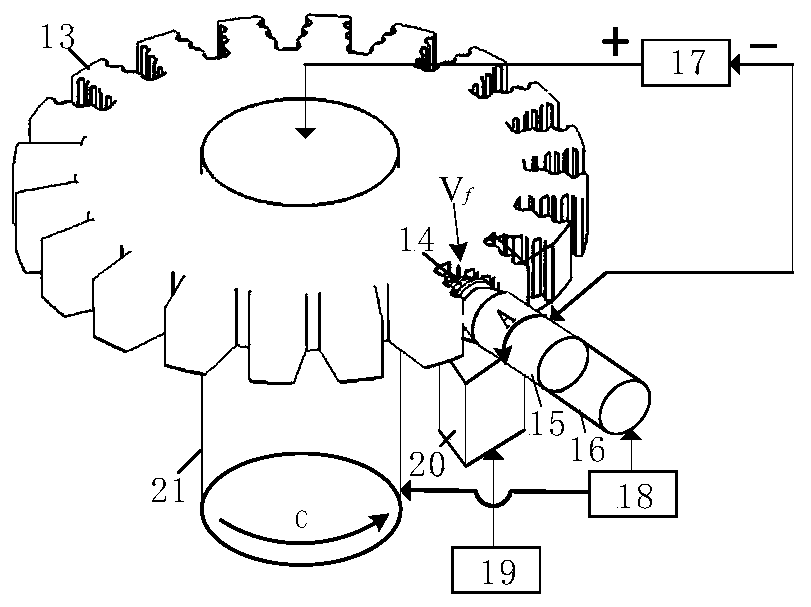

[0021] Such as Figure 1-3 As shown, the specific implementation process of a turbine tenon groove ultrasonic-assisted precision electrolytic grinding method is as follows:

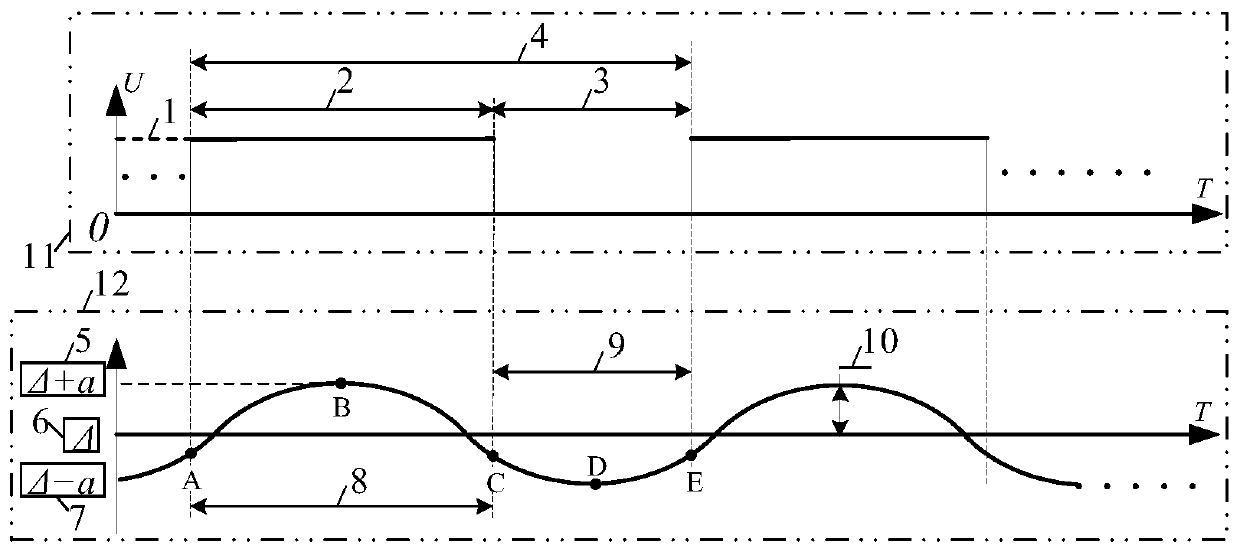

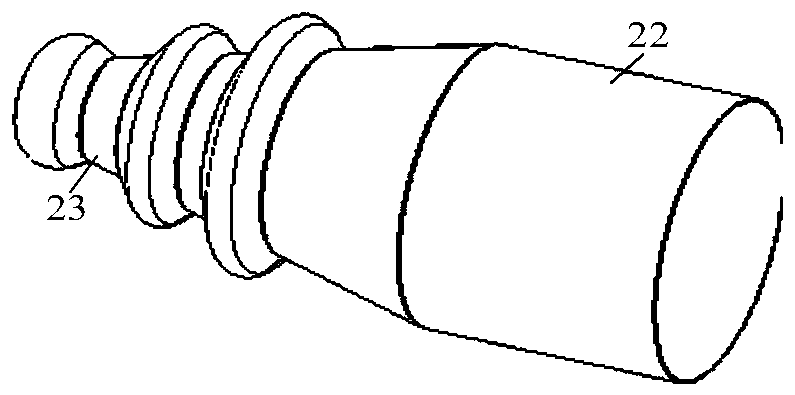

[0022] The tool grinding wheel 14 is connected to the negative pole of the power supply, and the semi-finished turbine disc 13 is connected to the positive pole of the power supply. The tool grinding wheel 14 is fed at a constant speed under the control of the multi-axis linkage drive system 18 of the machine tool, and the multi-dimensional ultrasonic vibration system 16 drives the tool grinding wheel 14 to vibrate at high frequency along its feeding direction , the value of the gap between poles changes regularly and periodically.

[0023] When the multi-dimensional ultrasonic vibration system 16 drives the tool grinding wheel 14 away from the machining surface of the turbine disk semi-finished produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com