Water-based environment-friendly paint used for lost foam casting mold for brass casting and preparation method of water-based environment-friendly paint

A technology of brass casting and environmentally friendly coatings, applied in casting molding equipment, coatings, casting molds, etc., can solve problems such as poor air permeability, and achieve the effects of good coating, improved suspension performance, and strong covering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

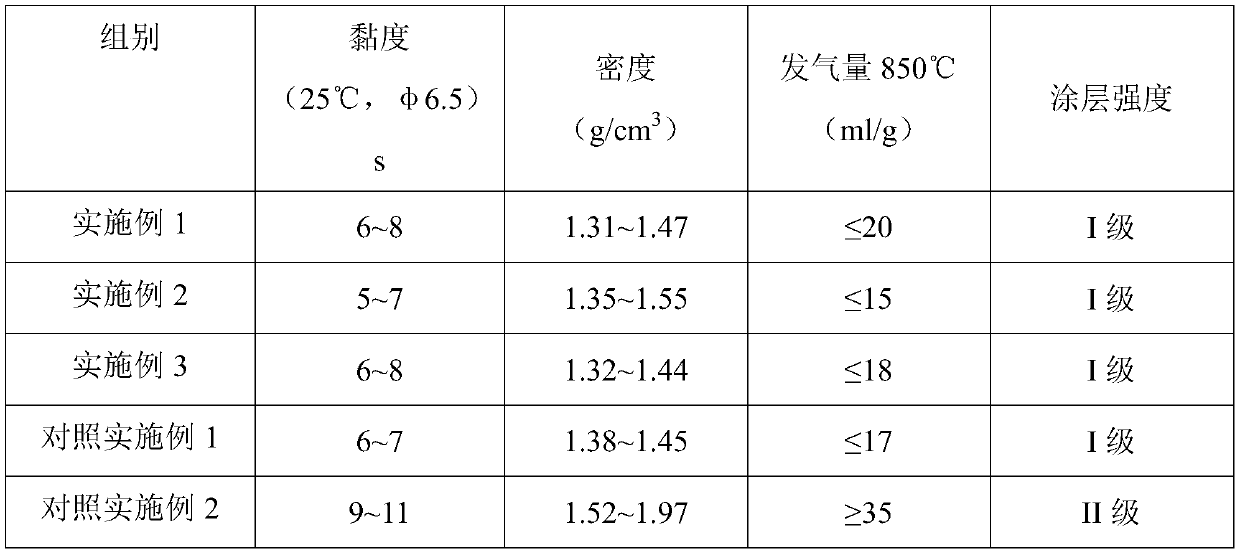

Examples

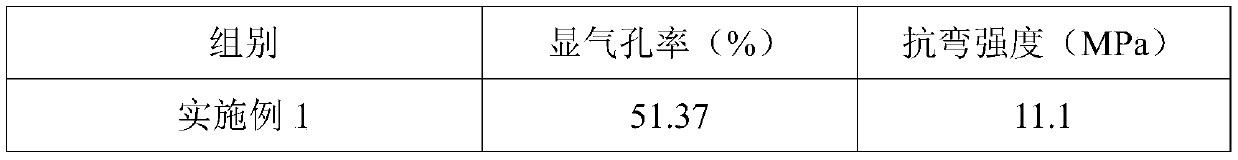

Embodiment 1

[0027] Embodiment 1: Prepare brass casting lost foam water-based environmental protection coating as follows:

[0028] 1. Preparation of raw materials:

[0029] Prepare porous glass-ceramics as follows:

[0030] (1) raw material waste glass, blowing agent NaCO 3 , SiC and sintering aid V 2 o 5 Mix according to the weight ratio of 85:7:5:3, then grind and pass through a 120 mesh sieve;

[0031] (2) Spread the mixed powder into a mold made of ceramic fiber paper, put it into a muffle furnace for programmed heating, and dry it in an environment of 480K for 2 hours;

[0032] (3) Then raise the temperature to 1173K at a rate of 20K / min and keep it for 30min, then raise the temperature to 1453K at a rate of 20K / min and keep it for 30min to obtain porous glass-ceramics. Porous glass-ceramics have a pore size of 0.58 to 6.22 microns.

[0033] 30 parts by weight of diatomite powder, 50 parts by weight of talc powder and 150 parts by weight of porous glass-ceramic powder are groun...

Embodiment 2

[0049] Embodiment 2: Prepare brass casting lost foam water-based environmental protection coating as follows:

[0050] 1. Preparation of raw materials:

[0051] Prepare porous glass-ceramics as follows:

[0052] (1) raw material waste glass, blowing agent NaCO 3 , SiC and sintering aid V 2 o 5 Mix according to the weight ratio of 90:3:4:3, then grind, and pass through a 150-mesh sieve;

[0053] (2) Spread the mixed powder into a mold made of ceramic fiber paper, put it into a muffle furnace for programmed heating, and dry it in an environment of 480K for 2 hours;

[0054] (3) Then raise the temperature to 1173K at a rate of 20K / min and keep it for 30min, then raise the temperature to 1453K at a rate of 20K / min and keep it for 30min to obtain porous glass-ceramics. Porous glass-ceramics have a pore size of 2.35 to 5.69 microns.

[0055] 50 parts by weight of diatomite powder, 70 parts by weight of talc powder and 250 parts by weight of porous glass-ceramic powder are grou...

Embodiment 3

[0058] Embodiment 3: Prepare brass casting lost foam water-based environmental protection coating as follows:

[0059] 1. Preparation of raw materials:

[0060] Prepare porous glass-ceramics as follows:

[0061] (1) raw material waste glass, blowing agent NaCO 3 , SiC and sintering aid V 2 o 5 Mix according to the weight ratio of 86:4:5:5, then grind, and pass through a 200-mesh sieve;

[0062] (2) Spread the mixed powder into a mold made of ceramic fiber paper, put it into a muffle furnace for programmed heating, and dry it in an environment of 480K for 2 hours;

[0063] (3) Then raise the temperature to 1173K at a rate of 20K / min and keep it for 30min, then raise the temperature to 1453K at a rate of 20K / min and keep it for 30min to obtain porous glass-ceramics. Porous glass-ceramics have a pore size of 1.11 to 3.54 microns.

[0064] 40 parts by weight of diatomite powder, 60 parts by weight of talc powder and 200 parts by weight of porous glass-ceramic powder are grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com