Strip steel uncoiling mechanism

A strip steel and chassis technology, applied in the field of strip steel uncoiling mechanism, can solve problems affecting strip steel uncoiling, coil strip steel loosening, coil strip steel slipping, etc., to achieve loosening prevention, firm and stable structure, and good load bearing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

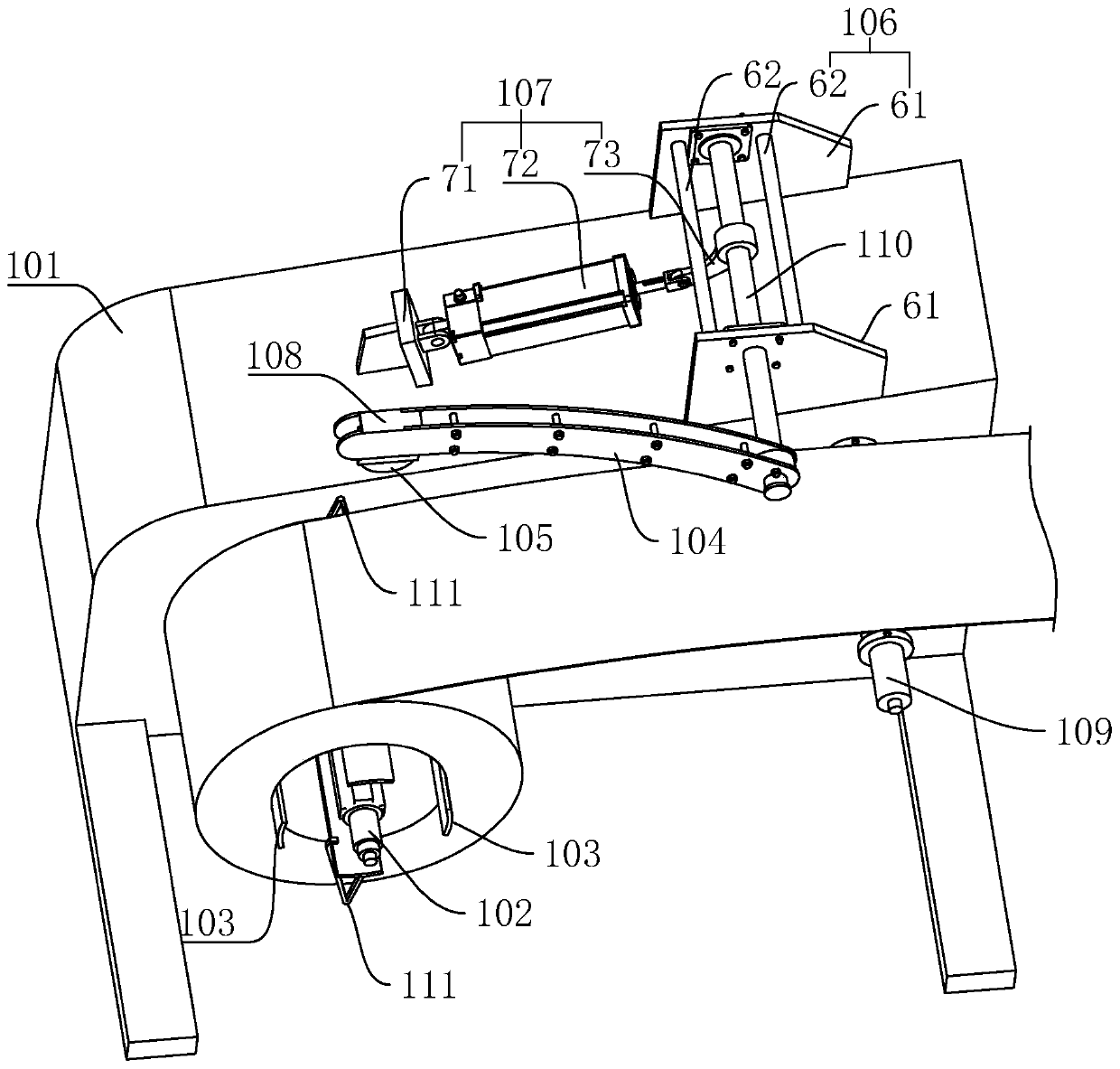

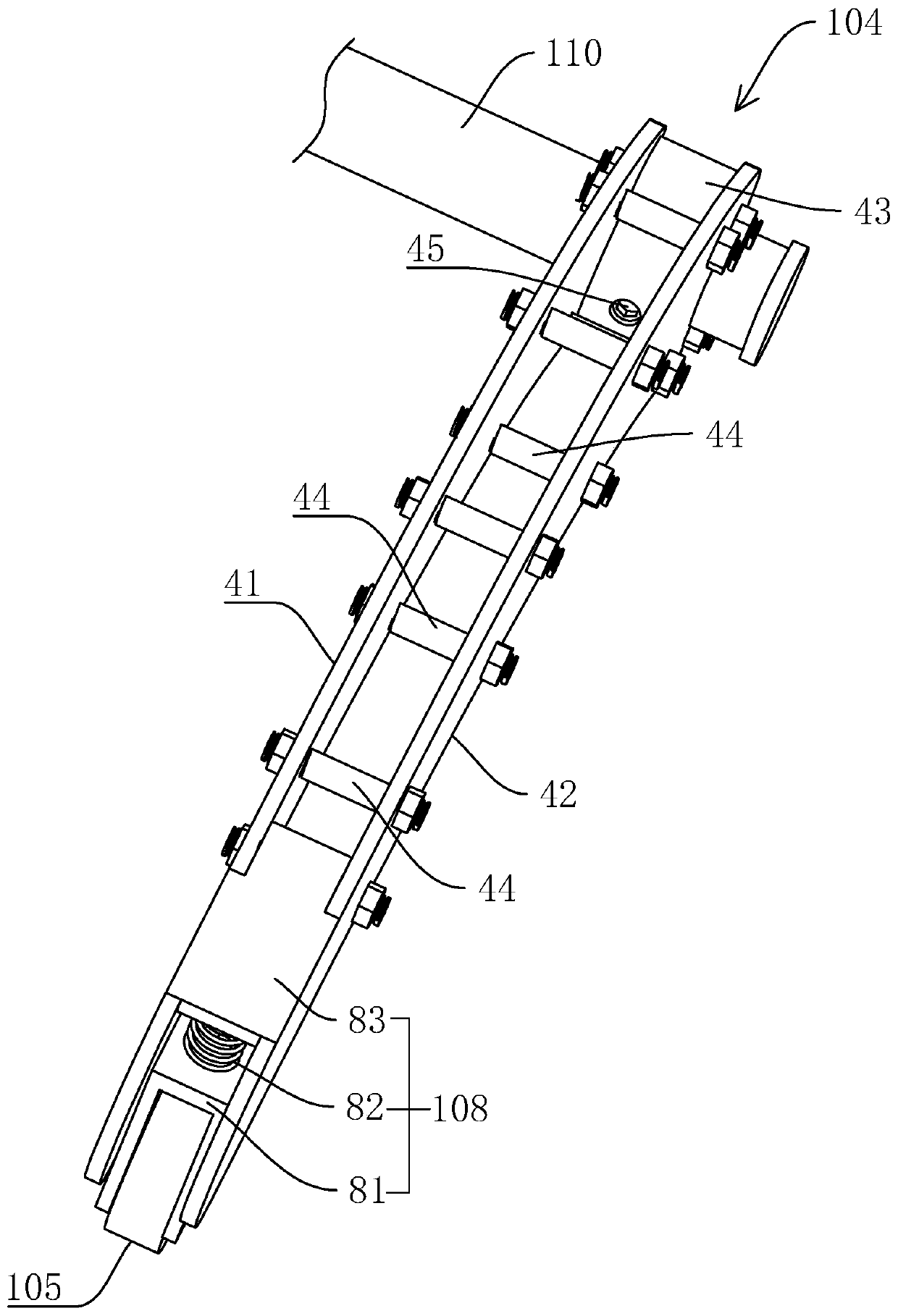

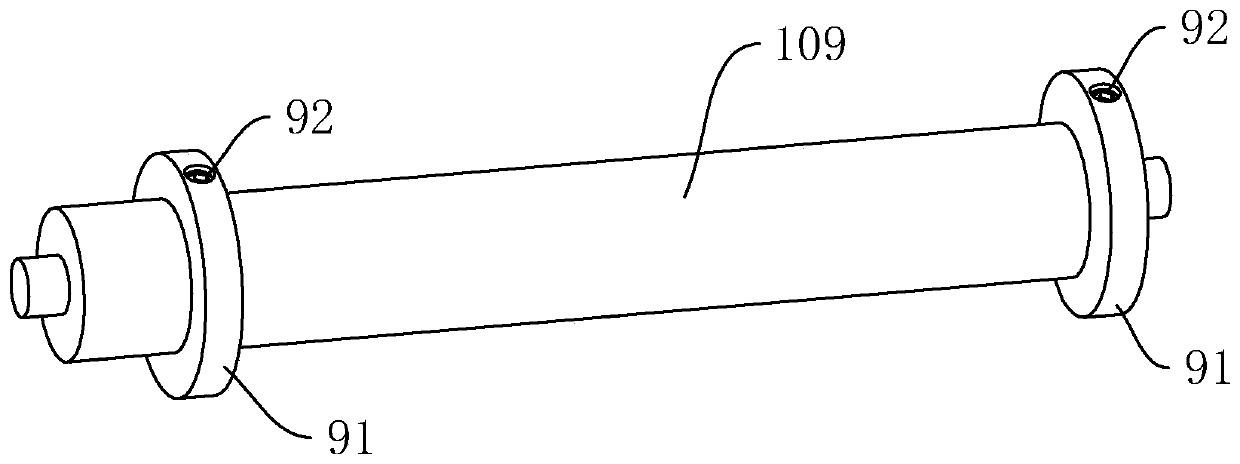

[0035] refer to figure 1, is a strip uncoiling mechanism disclosed in the present invention, comprising: a chassis 101, a power motor, an uncoiling spindle 102, a tension shoe 103, a guide roller 109, a rotating shaft 110, an arc arm 104, a pressure wheel 105, and a mounting frame 106 , the driving member 107 and the elastic component 108, the power motor is arranged in the cabinet 101, the unwinding main shaft 102 is rotated and arranged on one side of the cabinet 101, the power motor drives the unwinding main shaft 102 to rotate, and the unwinding main shaft 102 is provided with four expansion pads 103, The coiled steel strip is sheathed on the expansion shoe 103 .

[0036] Mounting frame 106 is installed on the top surface of cabinet 101, and guide roller 109 is located at the side of cabinet 101 and is positioned at the oblique top of unwinding main shaft 102, and rotation shaft 110 is arranged on the mounting frame 106 and is positioned at the top of guiding roller 109, u...

Embodiment 2

[0046] refer to Figure 4 , is a strip steel uncoiling mechanism disclosed in the present invention. The difference from Embodiment 1 is that the driving member 107 includes: a servo motor 74 and a reduction box 75, and the servo motor 74 and the reduction box 75 are installed on the cabinet 101 to reduce the speed. The box 75 is connected between the output shaft of the servo motor 74 and the rotation shaft 110 . The servo motor 74 can very precisely control the forward and reverse rotation of its output shaft, and then reduce the speed of the output shaft of the servo motor 74 through the reduction box 75, and then drive the rotating shaft 110 to rotate. The structure of the driving member 107 of the above design is simple, Easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com