A kind of fully dry sorting method for iron ore

A fully dry and dry magnetic separation technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increased processing capacity, high dry grinding capacity, and ineffective use of tailings. Achieve the effects of reducing processing pressure, increasing recovery rate, reducing equipment maintenance and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

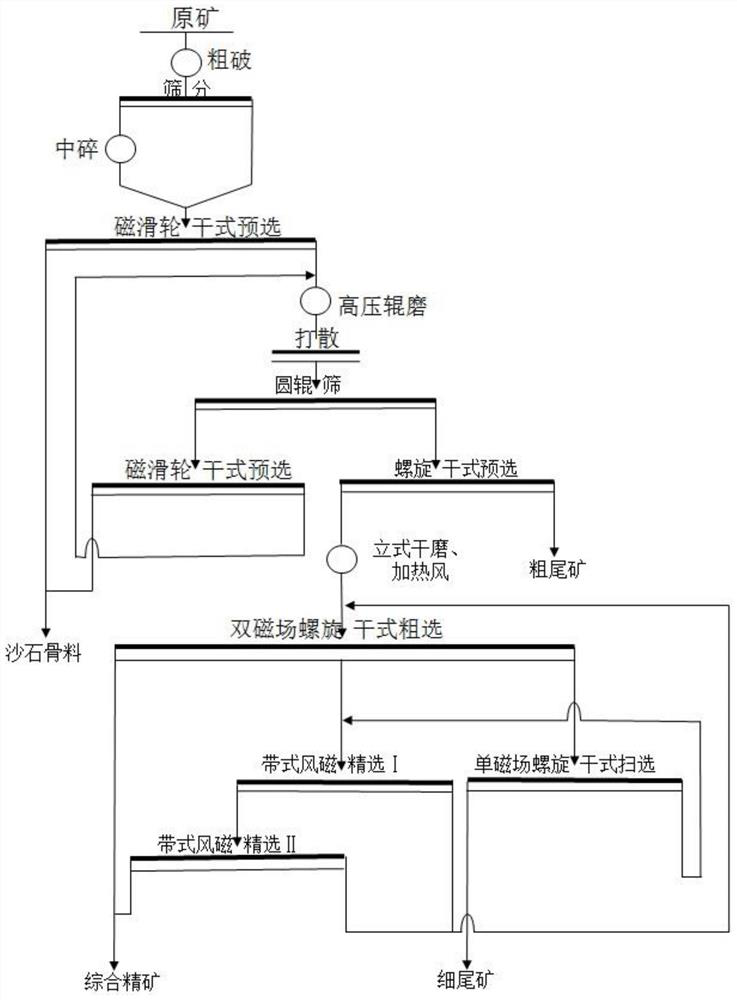

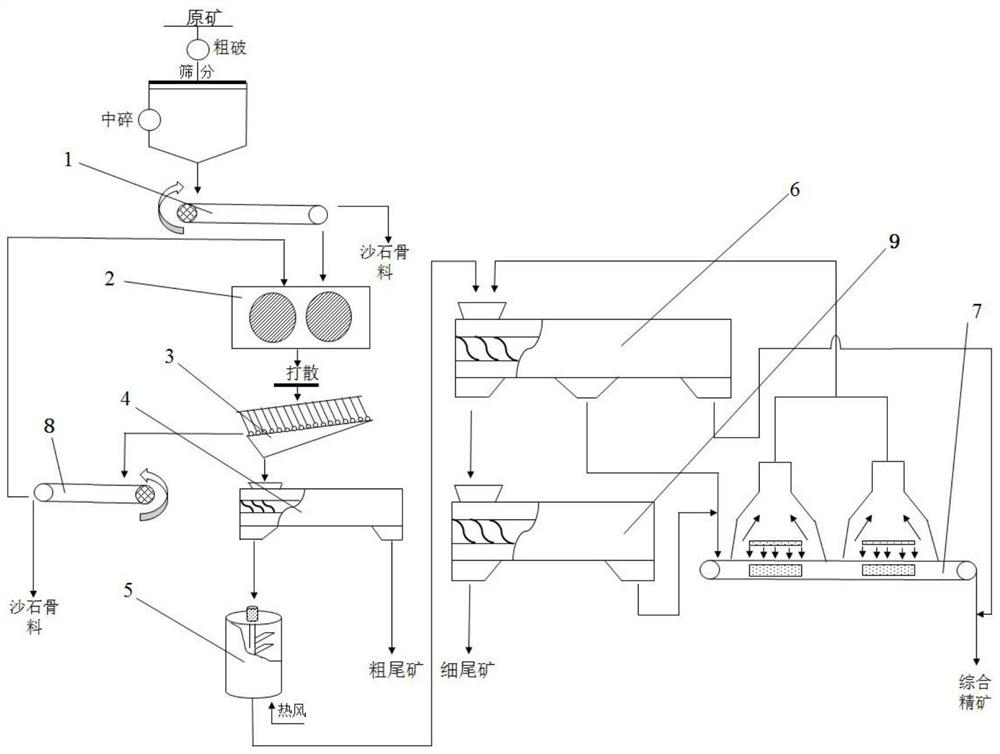

[0042] Such as figure 1 As shown, the invention discloses a kind of iron ore full-dry sorting method, the equipment adopted is such as figure 2 As shown, it includes a first magnetic pulley 1, a high pressure roller mill 2, a round roller screen 3, a first single magnetic field spiral dry magnetic separator 4, a vertical dry mill 5, a double magnetic field spiral dry magnetic separator 6, Belt-type air-magnetic dry separator 7, the second magnetic pulley 8, the second single magnetic field spiral dry magnetic separator 9, the iron ore full-dry sorting method includes the following steps:

[0043] Step 1: coarsely crush and screen the iron-containing raw ore, pass the material on the sieve through a stage of intermediate crushing, and then pass the first magnetic pulley 1 together with the material under the sieve for dry pre-selection;

[0044] Step 2, sending the concentrated ore after the dry pre-selection by the first magnetic pulley 1 into the high-pressure roller mill 2...

Embodiment 2

[0059] The iron content of the iron ore used is 31.20%, the iron-containing minerals are mainly magnetite, limonite and hematite, and the particle size of the raw ore is >50mm.

[0060] An iron ore full-dry sorting method, the specific implementation steps are as follows:

[0061] 1. The raw iron ore is roughly broken, screened, and medium crushed until the particle size reaches -20mm, and it is pre-selected by the first magnetic pulley 1 with a magnetic field strength of 3800Gs, and the iron content of the sand aggregate removed is 9.23 %, the yield is 18.24%.

[0062] 2. After the pre-selected concentrate is passed through the high-pressure roller mill, it passes through the round roller screen 3 with a distance between the rollers of 6mm, and the product on the screen is pre-selected by the second magnetic pulley 8 with a magnetic field strength of 3400Gs. The iron content of the sand and stone aggregate removed is 7.32%, the yield is 4.31%, the second magnetic pulley 8 pr...

Embodiment 3

[0066] The iron content of the iron ore used is 33.27%, the iron-containing minerals are mainly magnetite, specularite and hematite, and the particle size of the raw ore is >50mm.

[0067] An iron ore full-dry sorting method, the specific implementation steps are as follows:

[0068] 1. The raw iron ore is roughly broken, screened, and medium crushed until the particle size reaches -25mm, and it is pre-selected by the first magnetic pulley 1 with a magnetic field strength of 3700Gs, and the iron content of the sand aggregate removed is 11.23 %, the yield is 16.24%.

[0069] 2. After the pre-selected concentrate is passed through the high-pressure roller mill, it passes through the round roller screen 3 with a distance between the rollers of 8mm, and the product on the screen is pre-selected by the second magnetic pulley 8 with a magnetic field strength of 3500Gs. The iron content of the sand and gravel aggregate thrown away is 7.79%, the yield rate is 7.44%, the second magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com