A kind of hydrodeoxygenation solid acid catalyst ni/ceo 2 -al 2 o 3

A ceo2-al2o3, deoxidized solid technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, catalysts, carbon compound catalysts, etc., can solve the cost of precious metals and pollution of sulfur-containing catalysts, reduce catalytic activity, and easy carbon deposition and other problems, to achieve the effect of good reusability, simple preparation process and strong anti-sintering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

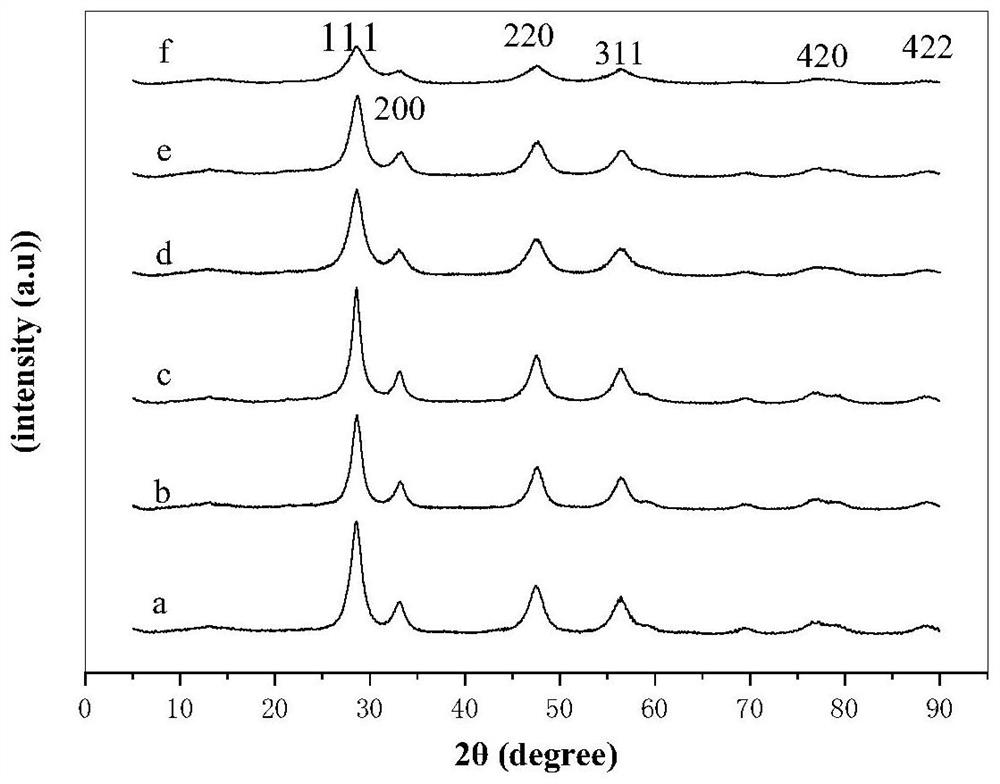

[0031] 1. Preparation of Ni / CeO 2 -Al 2 o 3 catalyst

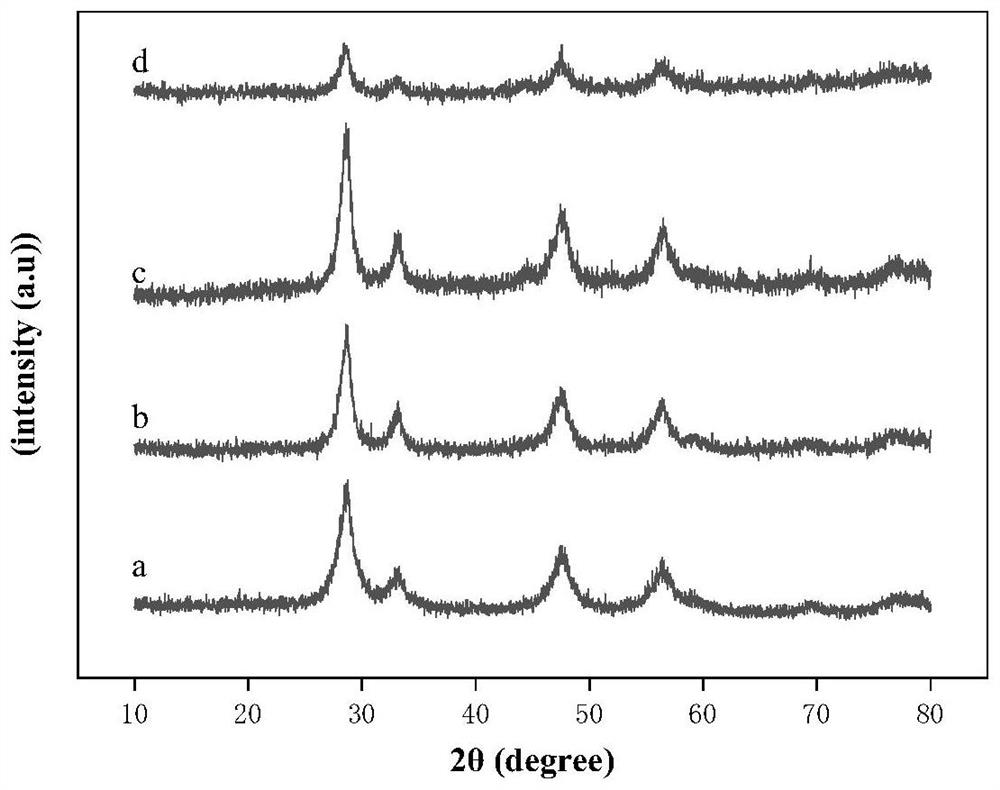

[0032] Ce(NO 3 ) 3 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is dissolved in deionized water at a molar ratio of 3:1 to form a solution with a total concentration of 0.3mol / L, and the addition of NO 3 -3:1 molar ratio of urea, stir evenly until the solution is clear, then transfer the mixed solution to a polytetrafluoroethylene-lined reactor for crystallization at 110°C for 4 hours, cool to room temperature, and suction filter the formed precipitate , the filter cake was washed with deionized water until neutral (pH = 7), and dried at a constant temperature at 80°C overnight. The resulting solid was ground and sieved, and the 100-mesh powder was placed in a box-type muffle furnace with a temperature increase of 2°C / min. Calcined at 500°C for 4 hours, and the CeO containing weak acid and medium strong acid was obtained after cooling. 2 -Al 2 o 3 carrier;

[0033] Ni(NO 3 ) 2 ·6H 2 O, CeO prepared above 2 -Al 2 o 3 ...

Embodiment 2

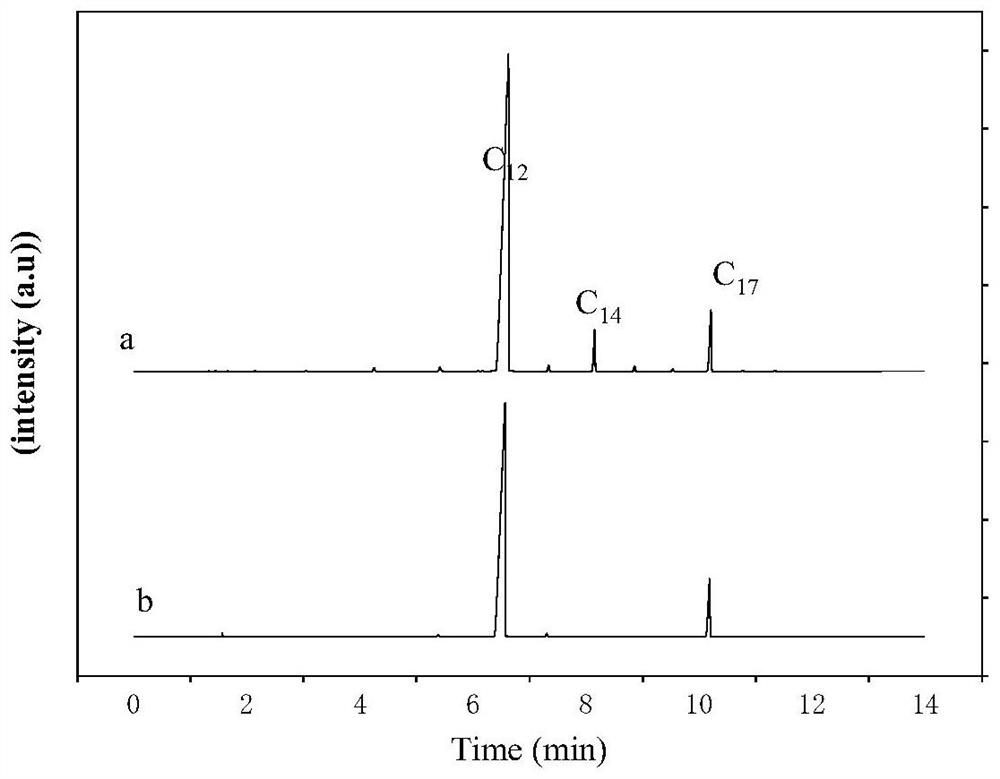

[0036] The operation procedure of Example 2 is the same as that of Example 1, but the molar ratio of Ce and Al in the catalyst is 0.5:1, and the molar yield of the biofuel product n-heptadecane is 77%, and the product purity is 98% by mass.

Embodiment 3

[0037] The operation steps of Example 3 are the same as in Example 1, but the molar ratio of Ce and Al in the catalyst is 1:1, and the molar yield of the biofuel product n-heptadecane is 94%, and the product purity is 98% by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com