Foam fire extinguishing agent with high-efficiency environment-friendly evaporation-inhibiting function and preparation method of foam fire extinguishing agent

A foam fire extinguishing agent, an environmentally friendly technology, applied in fire protection equipment and other directions, can solve the problems of re-ignition, can not well suppress the volatilization of hot oil, etc., achieve the effect of preventing volatilization, controlling the natural and combustion accidents of automobiles, and improving the performance of coverage inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

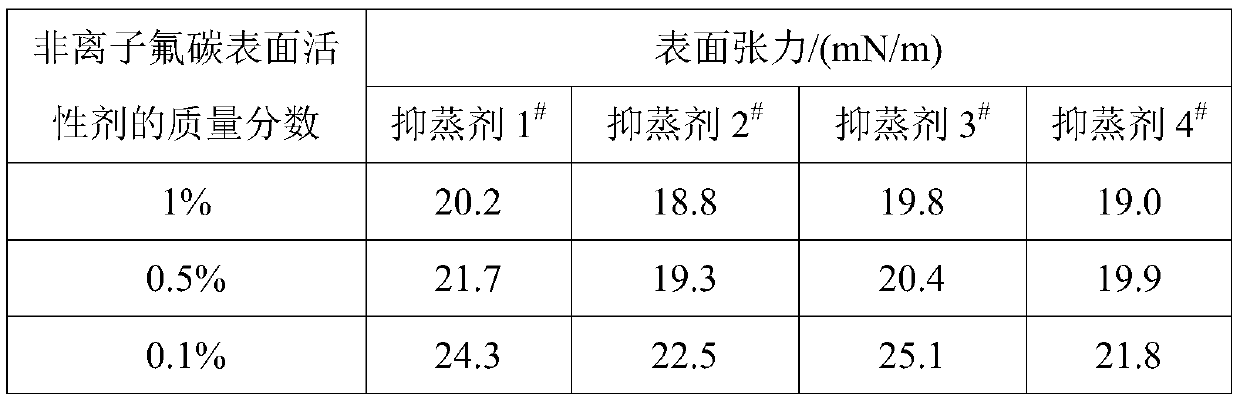

[0028] Fire extinguishing agent formula (6% type) with high efficiency, environmental protection and anti-steam function:

[0029] Cocoyl Propyl Betaine CAB-35 10%, Betaine Fluorocarbon Surfactant F1157 1.0%, Evaporator 2.5%, Ethylene Glycol Butyl Ether 3.5%, Ethylene Glycol 4%, Urea 5%, Seaweed Sodium Hydroxide 0.5%, Sodium Hydroxymethylglycinate 0.3%, Water 73.7%

[0030] Production Process:

[0031] (1) at 1m 3 In the mixing kettle, add 710kg of water, start stirring, and control the temperature within the range of 20°C to 40°C.

[0032] (2) Slowly add 50kg of urea, 5kg of sodium alginate, 3kg of sodium hydroxymethylglycinate and other solid materials into the mixing kettle in sequence, and stir evenly.

[0033] (3) Add ethylene glycol 40kg, ethylene glycol butyl ether 35kg, CAB-35 100kg, F1157 10kg, steam suppressant 2 # Add 25kg to the mixing kettle and stir evenly.

[0034] (4) Rinse the pipeline with the remaining 27kg of water, adjust the pH to 8.0 with 20% NaOH, ...

Embodiment 2

[0042] Fire extinguishing agent formula (3% type) with high efficiency, environmental protection and steam suppression function:

[0043] Cocoylpropyl Betaine CAB-35 10%, Alkyl Glycoside APG0810 8%, Betaine Fluorocarbon Surfactant F1157 1.8%, Inhibitor 1 # 5%, ethylene glycol butyl ether 7%, glycerin 8%, urea 10%, cyan gum 0.5%, polyhexanide hydrochloride 0.3%, water 49.4%

[0044] Production Process:

[0045] (1) In a 1m3 mixing kettle, add 470kg of water and start stirring.

[0046] (2) Slowly add solid raw materials such as 100kg of urea, 3kg of polyhexanide hydrochloride, and 5kg of cyanogen gum into the mixing kettle in sequence, and stir evenly.

[0047] (3) Glycerin 80kg, ethylene glycol butyl ether 70kg, CAB-35 100kg, APG0810 80kg, F115718kg, steam suppressant 1 # Add 50kg to the mixing kettle and stir evenly.

[0048] (4) Rinse the pipeline with the remaining 24kg of water, adjust the pH to 8.5 with 20% NaOH, stir evenly, and pack into barrels to obtain the finished...

Embodiment 3

[0056] Fire extinguishing agent formula (6% type) with high efficiency, environmental protection and anti-steam function:

[0057] Cocoyl Propyl Betaine CAB-35 10%, Betaine Fluorocarbon Surfactant F1157 1.0%, Inhibitor 4 # 2.5%, butyl glycol ether 3.5%, ethylene glycol 4%, urea 5%, sodium alginate 0.8%, trichloro-2-hydroxy-diphenyl ether 0.3%, water 72.9%

[0058] Production Process:

[0059] (1) at 1m 3 In the mixing still, add 710kg water, start stirring.

[0060] (2) Slowly add solid raw materials such as 50 kg of urea, 8 kg of sodium alginate, and 3 kg of trichloro-2-hydroxy-diphenyl ether into the mixing kettle in sequence, and stir evenly.

[0061] (3) Add ethylene glycol 40kg, ethylene glycol butyl ether 35kg, CAB-35 100kg, F1157 10kg, steam suppressant 4 # Add 25kg to the mixing kettle and stir evenly.

[0062] (4) Rinse the pipeline with the remaining 19kg of water, adjust the pH to 8.0 with 20% NaOH, stir evenly, and pack into barrels to obtain the finished pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com