Method for preparing double-layer perovskite manganese oxide film material on monocrystalline silicon substrate through epitaxial growth

A double-layer perovskite and epitaxial growth technology, applied in the field of magnetic materials, can solve the problem of difficulty in synthesizing double-layer perovskite thin films, and achieve the effects of low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

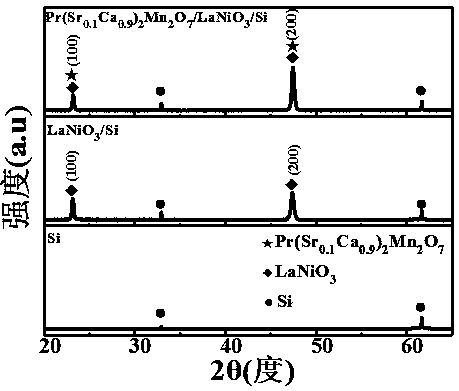

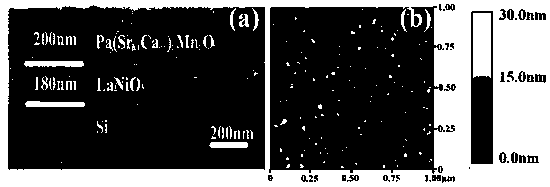

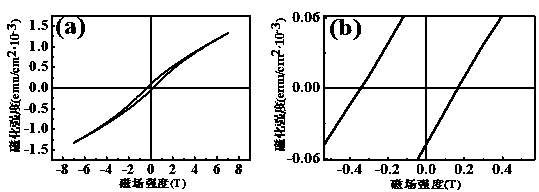

[0027] Using pulsed laser deposition technology, using Si(100) substrate as the substrate, LaNiO was sequentially deposited at 600 °C 3 thin film, deposited at 750°C on the top layer of Pr(Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 film;

[0028] (1) Using the sol-gel method, calcining at 1200°C and 1400°C for 48 hours respectively, to prepare the LaNiO needed for the experiment 3 and Pr(Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 target.

[0029] (2) Put the single crystal Si (100) substrate into the preparation chamber of the pulsed laser deposition system, and evacuate the preparation chamber of the pulsed laser deposition system to ≤5×10 -4 Pa, heating the substrate to 600°C, with LaNiO 3 The block material is used as the target material, the laser voltage is 23.0KV, the deposition rate is 3HZ, and the deposition times are 4000 times. In-situ annealing for 5 minutes, then continue to heat up to 750 ° C, with Pr (Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 The block material is used as the target material...

Embodiment 2

[0032] Using pulsed laser deposition technology, using Si(100) substrate as the substrate, LaNiO was sequentially deposited at 650 °C 3 thin film, deposited at 750°C on the top layer of Pr(Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 film;

[0033] (1) Using the sol-gel method, calcining at 1200°C and 1400°C for 48 hours respectively, to prepare the LaNiO needed for the experiment 3 and Pr(Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 target.

[0034] (2) Put the single crystal Si(100) substrate into the preparation chamber of the pulsed laser deposition system, and vacuum the preparation chamber of the pulsed laser deposition system to ≤5×10 -4 Pa, heating the substrate to 650°C, with LaNiO 3 The block material is used as the target material, the laser voltage is 23.0KV, the deposition rate is 3HZ, and the deposition times are 4000 times. In-situ annealing for 5 minutes, then continue to heat up to 750 ° C, with Pr (Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 The block material is used as the target material, t...

Embodiment 3

[0037] Using pulsed laser deposition technology, using Si(100) substrate as the substrate, LaNiO was sequentially deposited at 700 °C 3 thin film, deposited at 750°C on the top layer of Pr(Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 film;

[0038] (1) Using the sol-gel method, calcining at 1200°C and 1400°C for 48 hours respectively, to prepare the LaNiO needed for the experiment 3 and Pr(Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 target.

[0039] (2) Put the single crystal Si(100) substrate into the preparation chamber of the pulsed laser deposition system, and vacuum the preparation chamber of the pulsed laser deposition system to ≤5×10 -4 Pa, heating the substrate to 700°C, with LaNiO 3 The block material is used as the target material, the laser voltage is 23.0KV, the deposition rate is 3HZ, and the deposition times are 4000 times. In-situ annealing for 5 minutes, then continue to heat up to 750 ° C, with Pr (Sr 0.1 Ca 0.9 ) 2 mn 2 o 7 The block material is used as the target material, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com