Same-side multi-head resistance welding machine for frame and skin

A resistance welding machine and skinning technology, applied in resistance welding equipment, resistance electrode bases, electrode features, etc., can solve the problems of high grinding and anti-corrosion cost, low efficiency, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

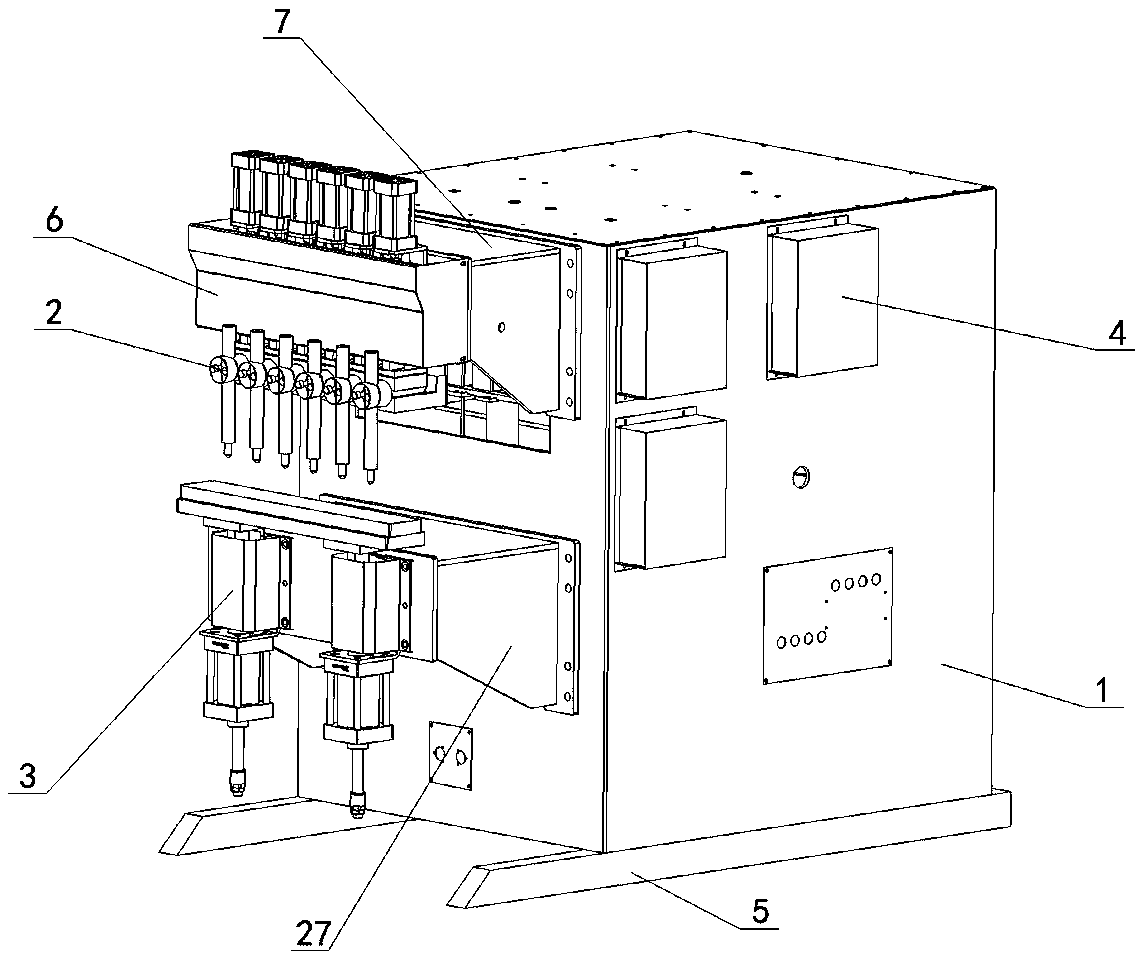

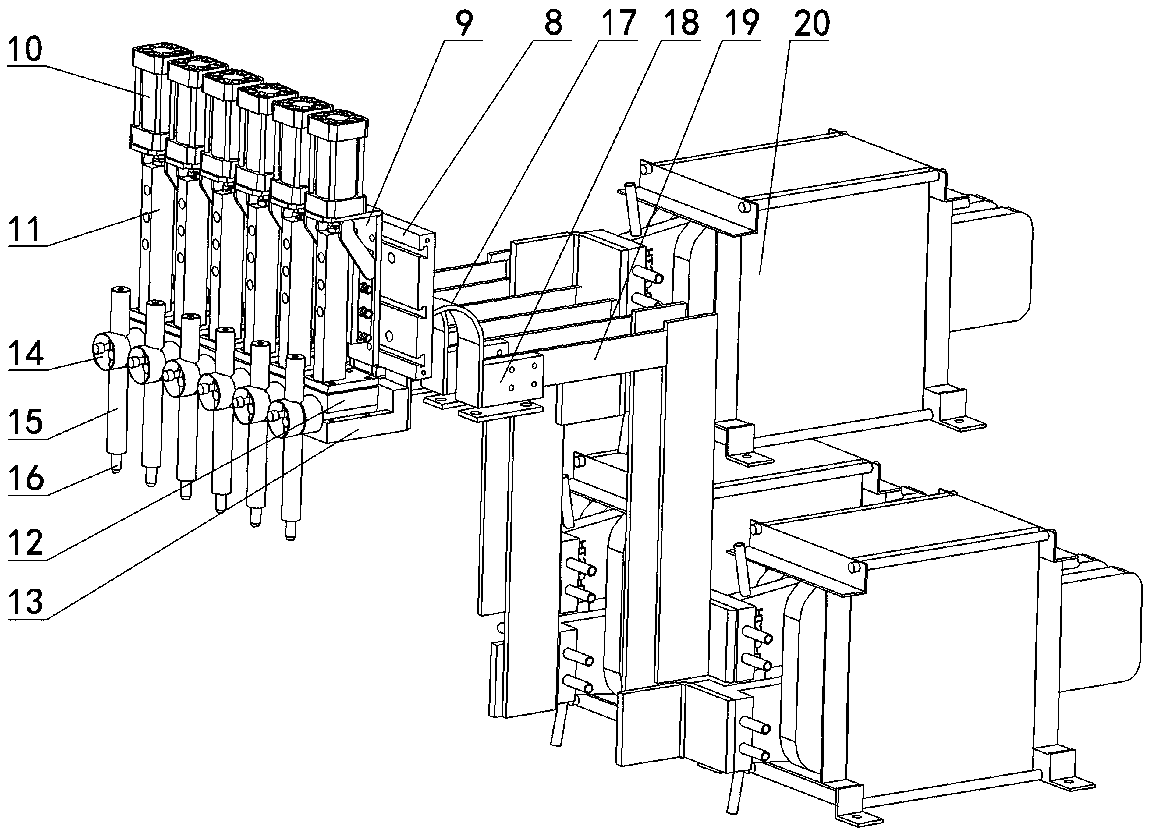

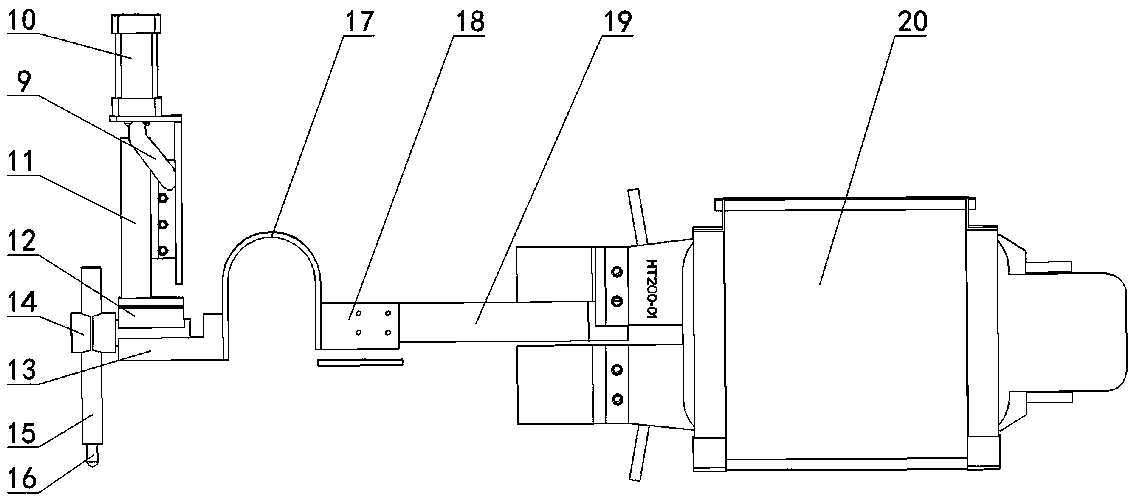

[0029] In order to make the purpose, technical scheme and advantages of the present invention more clear, the following will be combined with the appended figure 1 , attached figure 2 , attached image 3 And attached Figure 4 , to describe the present invention in more detail.

[0030] The present invention provides a multi-head resistance welding machine for the same side of the frame and skin, comprising a housing 1, a welding part 2 and a lower cantilever assembly 3; the welding part 2 includes a plurality of electrode heads 16; the lower cantilever assembly 3 includes a platform 21; The welding part 2 is arranged on the upper part of the casing 1, and the lower cantilever assembly 3 is arranged on the lower part of the casing 1; several electrode heads 16 are arranged directly above the platform 21; the welding part 2 includes a first mounting seat 7, a chute Plate 8, first cylinder seat 9, first cylinder 10, first piston arm 11, upper electrode block 12, lower electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com