Capillary chromatographic column device and liquid chromatographic separation method

A technology of capillary chromatographic column and separation method, which is applied in the field of capillary chromatographic column device and liquid chromatography separation, and can solve the problems of separation simplicity, reproducibility, sensitivity, separation efficiency and limited scope of application, separation sensitivity and sample volume Limited scope of application, chromatographic column specifications and large flow rate, etc., to avoid non-specific absorption loss, shorten drying time, and avoid corrosion consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a capillary chromatographic column device, and the capillary chromatographic column device is mainly used for liquid chromatography separation of proteins.

[0037] Such as figure 1 As shown, the capillary chromatographic column device of this embodiment mainly includes a first capillary 1 and a second capillary 2, the first capillary 1 and the second capillary 2 are quartz capillaries with a small diameter, and the outer diameter of the first capillary 1 is 280 -360um, preferably 360um, the inner diameter is preferably 50-180um, preferably 180um, the outer diameter of the second capillary 2 is 280-360um, preferably 360um, the inner diameter is 20-180um, preferably 50um, the first capillary 1 and the second The length of the second capillary 2 can be selected according to installation requirements. In this embodiment, the length and inner diameter ratio of the first capillary 1 is 2cm:180um to 10cm:100um, the length and inner diameter ratio of ...

Embodiment 2

[0047] This embodiment provides a liquid chromatographic separation method based on the capillary chromatographic column device in the first embodiment above, and this liquid chromatographic separation method is a liquid chromatographic separation method.

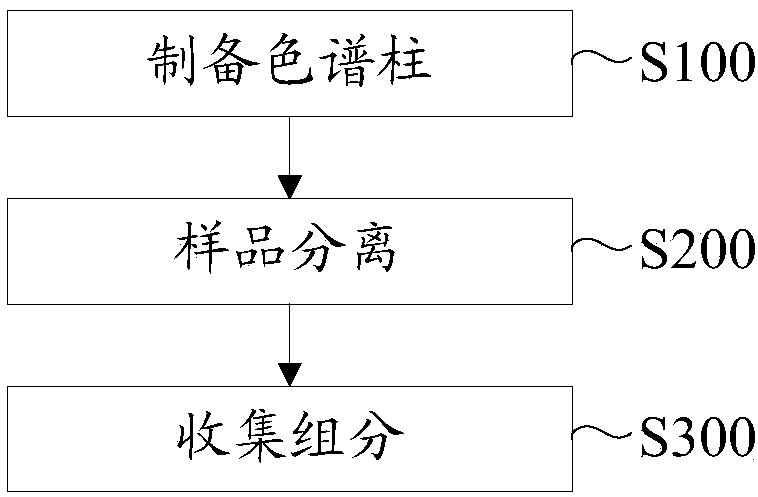

[0048] Such as figure 2 Shown, this liquid chromatography separation method comprises the steps:

[0049] S100: preparing a chromatographic column;

[0050] Select a quartz capillary with an outer diameter of 360um and an inner diameter of 180um, and use a laser microelectrode puller (pin puller) to stretch one end of the quartz capillary to form a tapered structure to form the first capillary 1, and then use the column material to fill the equipment Fill the C18 column material into the first capillary tube 1 as the separation column material 4, and the length of the C18 column material filling is 4cm; select a quartz capillary tube with an outer diameter of 360um and an inner diameter of 50um as the second capillary tub...

Embodiment 3

[0071] In this example, human plasma was used to remove high-abundance proteins and enzymolyzed complex peptide samples (normal human plasma samples were first removed from high-abundance proteins, and then the peptides produced by trypsin enzymolysis) were used for liquid chromatographic separation and mass spectrometric identification.

[0072] The complex peptide samples obtained by enzymatic hydrolysis after removal of high-abundance proteins from human plasma were separated by the liquid chromatography separation method in the above-mentioned Example 2, and the separated components were analyzed by the mass spectrometry identification method in the above-mentioned Example 2, and specifically identified The results are shown in Table 2 below:

[0073] Table 2

[0074] Separation test name Total protein Plasma_A_HPLC_20frac 1070 Plasma_A_micro_20frac 1092

[0075] In Table 2, "Plasma_A_HPLC_20frac" is the mass spectrometry identification protei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com