A microwave plasma chemical vapor deposition device

A technology of chemical vapor deposition and microwave plasma, which is applied in the direction of chemical reactive gas, gaseous chemical plating, chemical instruments and methods, etc., can solve the problem of uneven gas distribution on the surface of the sample table, etching of the dielectric window, and poor focusing ability and other problems, to achieve the effect of solving the problem of plasma etching, good homogenization effect, and realizing the feeding of high-power microwave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

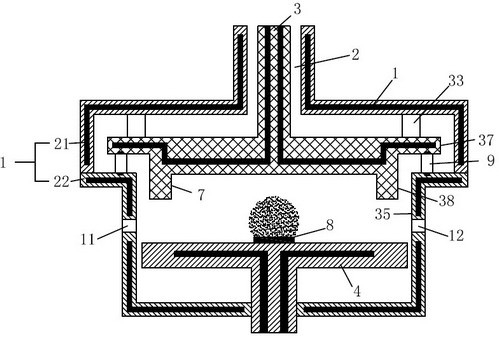

[0033] Such as figure 1 As shown, a microwave plasma chemical vapor deposition device of the present invention includes: the reaction chamber 1 includes an upper chamber 21 and a lower chamber 22, the bottom of the reaction chamber 1 is provided with a sample stage 4 for placing a substrate 8, and the reaction chamber 1 The top is provided with a central axis 3, the reaction chamber 1 and the central axis 3 form a quasi-coaxial waveguide 2, the central axis 3 extends into the reaction chamber, and the side of the central axis facing the sample stage 4 is provided with a concave structure surface 7; the reaction chamber 1. A horizontal air inlet 11 and a horizontal air outlet 12 are provided; in the coaxial waveguide 2, a sealing insulating member 9 and an insulating support member 33 are arranged; the lower end surface of the central axis 2 is lower than the sealing The lower end surface of the insulating member 9 and the lower end surface of the insulating support member 33; ...

Embodiment 2

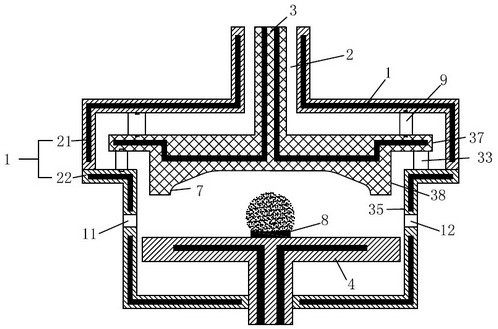

[0039] Such as figure 2 As shown, the concave structure surface 7 of the central axis 3 adopts a cylindrical concave surface, and many chamfers and fillets are added to the cylindrical concave surface 7 . Meanwhile, the sealing insulating part 9 is located between the central shaft 3 and the upper cavity 21 , and the insulating support 33 is located between the central shaft 3 and the lower cavity 22 . These two points are the differences between this embodiment and embodiment 1.

[0040] The change of the shape of the surface 7 of the concave structure has a certain influence on the electric field intensity and the plasma density above the center of the sample stage 4 .

[0041] The sealing insulator 9 is positioned between the central shaft 3 and the upper cavity 21, and the insulating support 33 is positioned between the central shaft 3 and the lower cavity 22, and the pre-loaded compression force is also sufficient when there is no vacuum in the cavity. Sufficient for a...

Embodiment 3

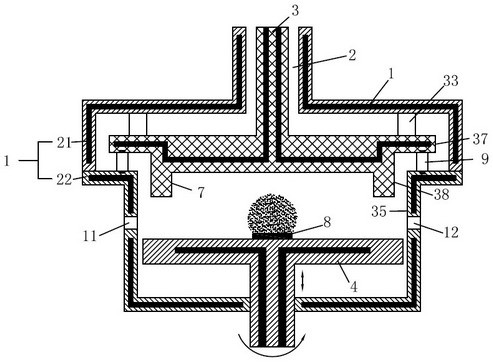

[0043] Such as image 3 As shown, the sample stage 4 can be adjusted up and down, and can be rotated. These two points are the differences between this embodiment and embodiment 1. The up and down adjustment of the sample stage 4 can adjust the resonant frequency of the reaction chamber 1 and can adjust the form of the plasma. The sample stage 4 can be rotated, and the gas flow rate of the gas inlet 11 is matched with the rotation speed of the sample stage 4, which can realize the homogenization of the reaction gas on the surface of the substrate 8, and can better realize the uniform growth of the diamond film, especially for large-area substrates. The doping uniformity of the bottom, the improvement effect is more obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com