Contact hole etching method, integrate circuit (IC) manufacturing method and IC

A contact hole etching and integrated circuit technology, which is applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of semiconductor device leakage, insufficient etching, contact hole connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

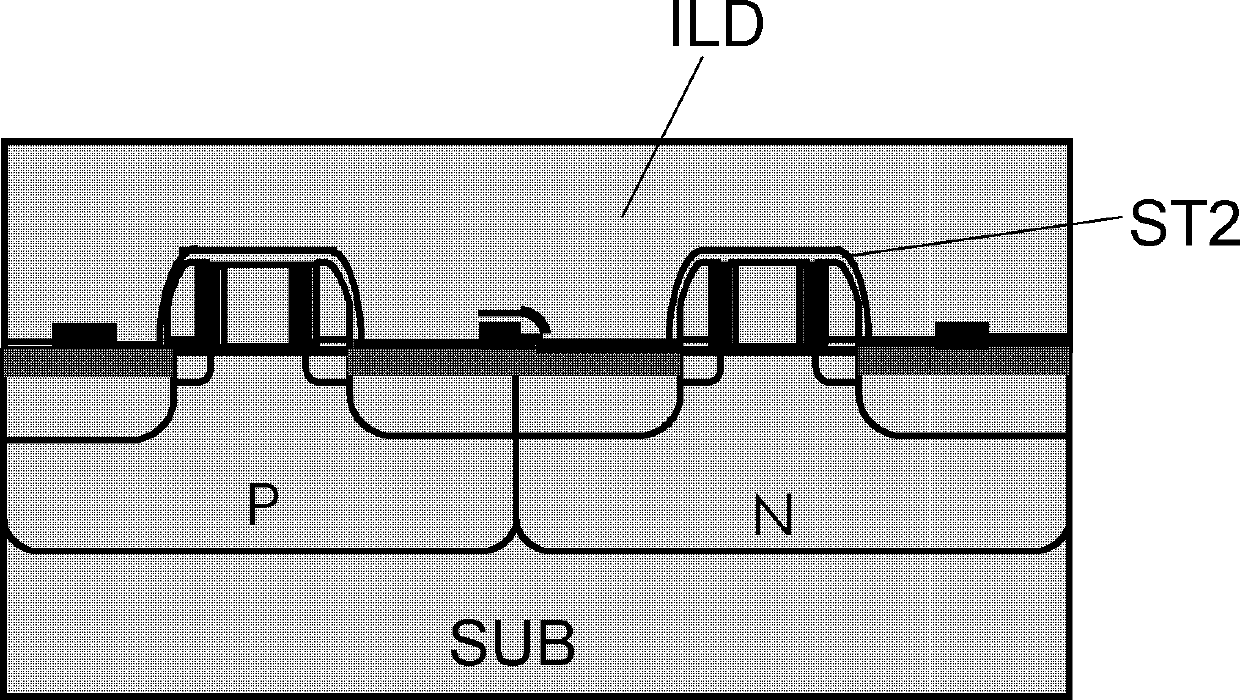

[0024] The following will refer to Figure 1 to Figure 5 A contact hole etching method according to an embodiment of the present invention will be described. As shown in the figure, the contact hole etching method according to the embodiment of the present invention includes the following steps:

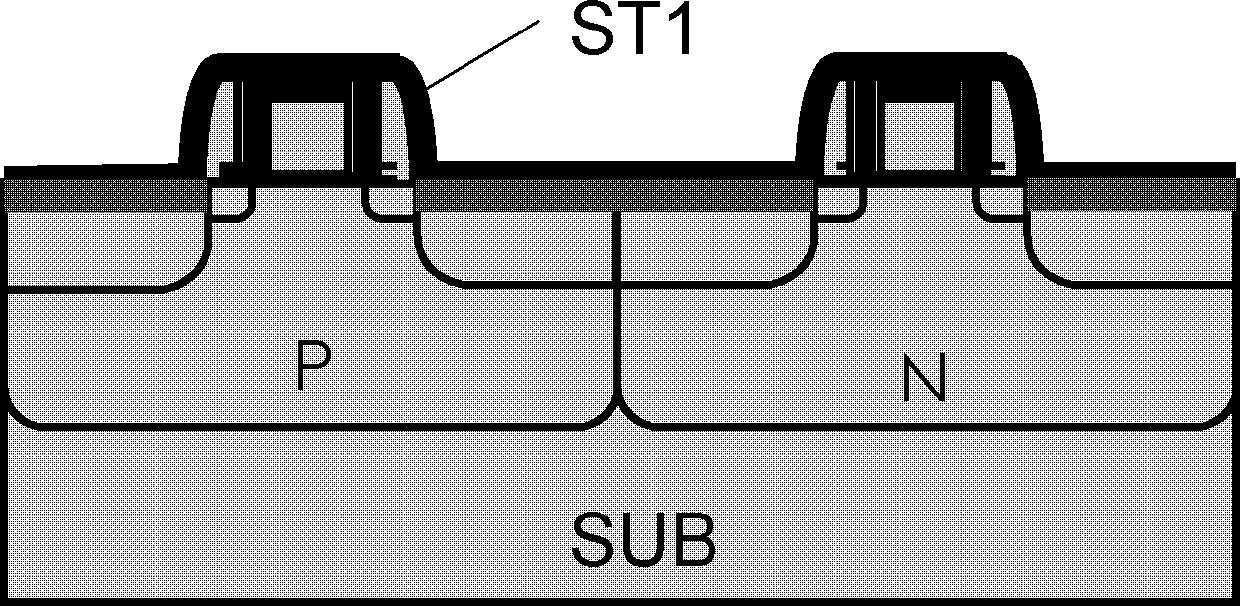

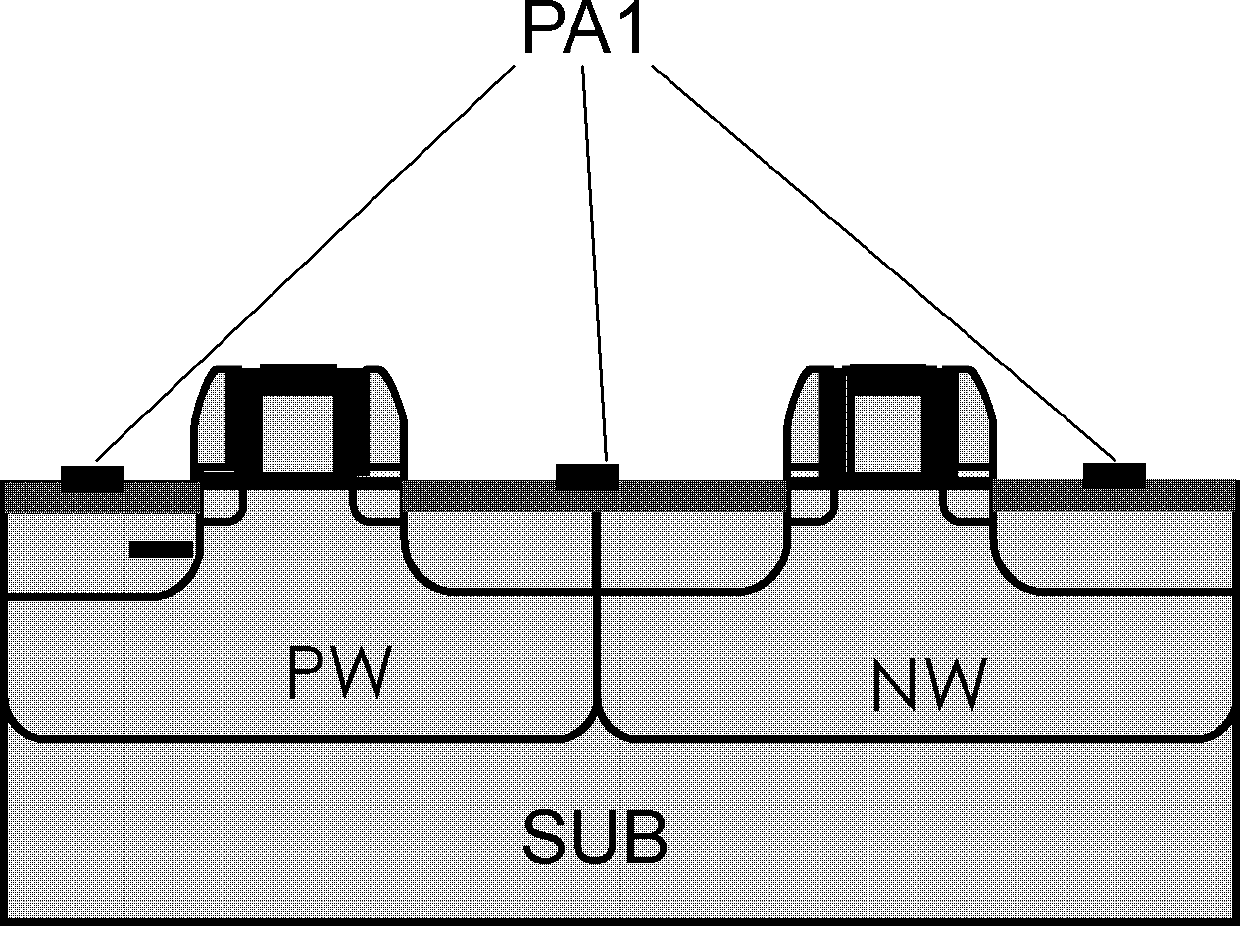

[0025] The first contact hole etch stop layer forming step is used to form the first contact hole etch stop layer ST1. figure 1 A schematic diagram schematically shows a step of forming a first contact hole etching barrier layer in a contact hole etching method according to an embodiment of the present invention. Such as figure 1 As shown, a P well PW and an N well NW are arranged on the semiconductor substrate SUB; specifically, the P well PW is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com