A preparation method of composite electrocatalytic material for alkaline electrocatalytic hydrogen evolution

An electrocatalytic material and electrocatalytic technology, applied in the field of electrocatalysis, can solve the problems of poor electrocatalytic hydrogen evolution performance, unsatisfactory performance of synthetic composite materials, high raw material cost, easy control of preparation conditions, promotion of electrocatalytic activity, The effect of uniform and firm coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

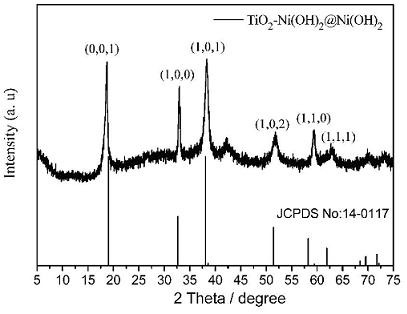

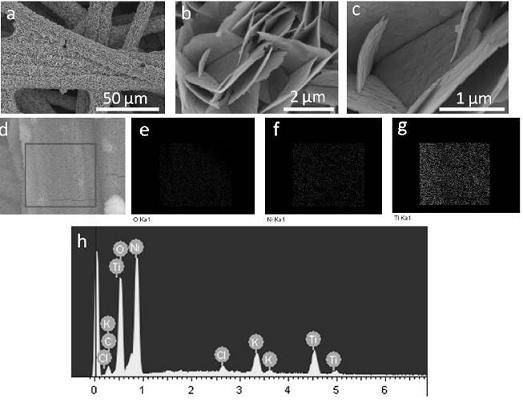

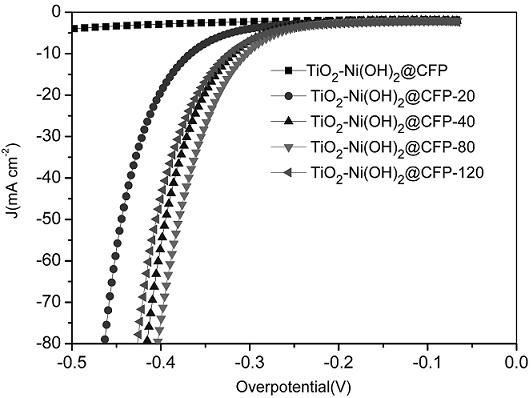

[0032] Concrete implementation steps of the present invention are as Figure 6 shown.

[0033] The raw material that present embodiment adopts is Ni(NO 3 ) 2 , NH 4 F, CO(NH 2 ) 2 .

[0034] Weigh 0.725 g of Ni(NO 3 ) 2 ·6H 2 O, 0.185 g NH 4 F and 0.625 g CO(NH 2 ) 2 Stir rapidly until it is completely dissolved, then continue to stir for 10 minutes to obtain a mixed solution, mix and dissolve in 40 ml of water;

[0035] Then take a piece of carbon fiber paper (CFP) and cut it into 2×3cm 2 block, ultrasonic cleaning in acetone, ethanol and water respectively for 15min, take out and weigh;

[0036] Then pour the above solution into the inner tank of the 50mL reaction kettle, and add a piece of washed 2×3cm 2 CFP, sealed reaction kettle kept at 130°C for 12h, washed with deionized water and absolute ethanol, dried at 80°C for 6h, weighed the mass of the precursor loaded on the carbon fiber paper;

[0037] The light green Ni(OH) covered with light green Ni(OH) synt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com