Organic and inorganic compound passivation solution and passivation method

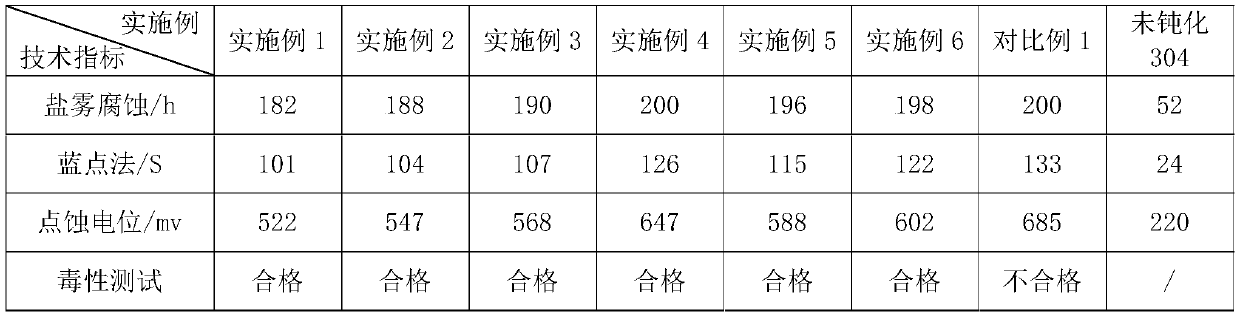

A technology of inorganic compounding and passivation liquid, applied in the field of passivation liquid, can solve the problems of unstable products and passivation production, and achieve the effect of improving anti-corrosion effect and protection life, increasing fingerprint resistance and improving protection life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

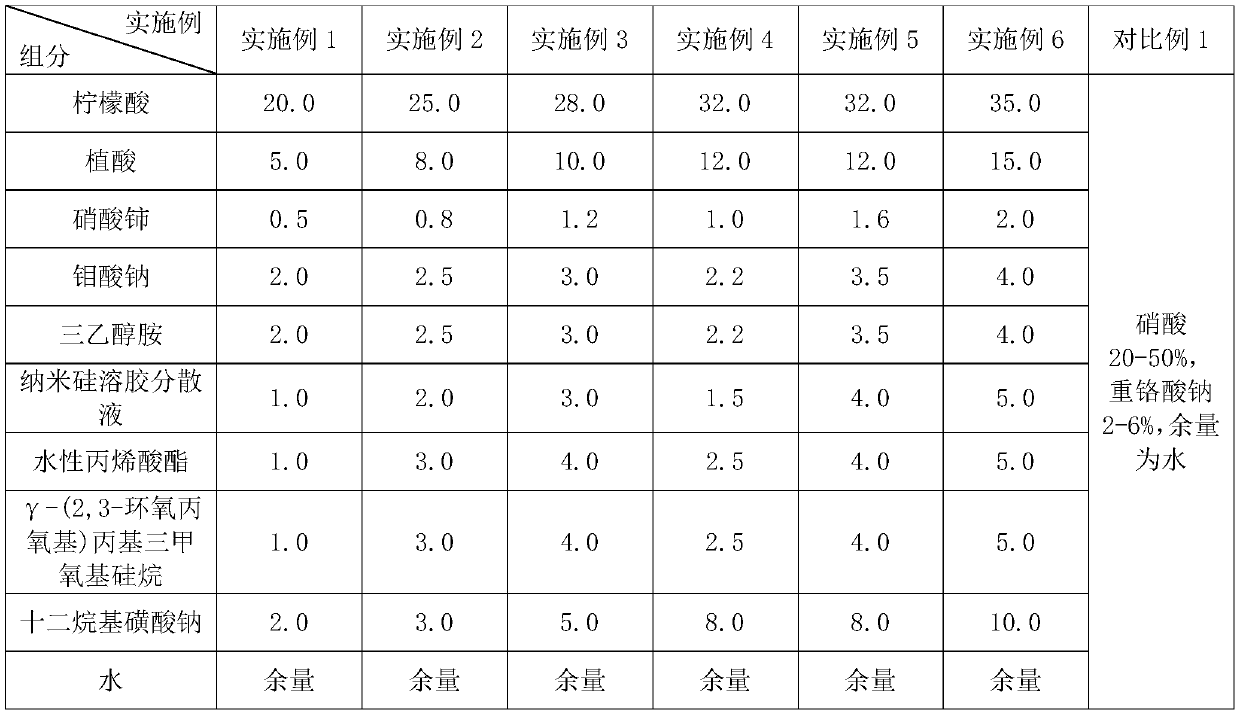

[0035] An environment-friendly passivation solution for stainless steel products, the content of each component by mass percentage is: 20.0% citric acid, 5.0% phytic acid, 0.5% cerium nitrate, 2.0% sodium molybdate, 2.0% triethanolamine, nano-silica sol Dispersion liquid 1.0%, water-based acrylate 1.0%, γ-(2,3-glycidoxy)propyltrimethoxysilane 1.0%, sodium dodecylsulfonate 2.0%, and the balance is water;

[0036] Its passivation method includes the following steps:

[0037] Pretreatment of stainless steel products: use cleaning agent to clean the surface of stainless steel products by soaking or spraying for 3 minutes; then use 1-2 channels of tap water for immersion cleaning for 5 minutes;

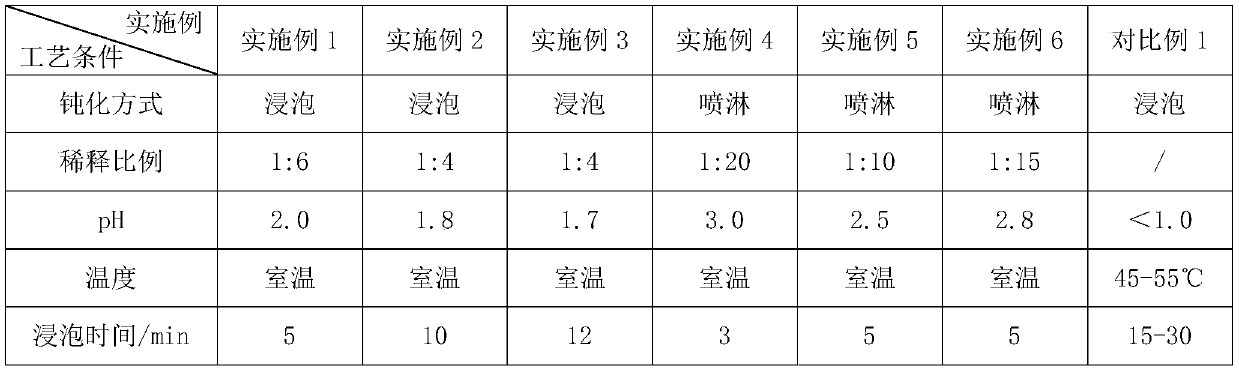

[0038] Passivation solution preparation: Dilute the prepared passivation solution stock solution with deionized water, the dilution ratio is 1:6, and the pH value of the diluted passivation solution is about 2.0;

[0039] Passivation: Use the diluted passivation solution to pickle and pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com