Batch scraping calcined sand stone-like coating as well as preparation method and application thereof

A technology of calcined sand and real stone paint, which is applied in the field of building coatings, can solve the problems of unguaranteed construction thickness and consumption, different coating effects, and affecting coating effects, so as to ensure the thickness and fluency of batch scraping and save energy Effects of materials, improvement of construction performance and storability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

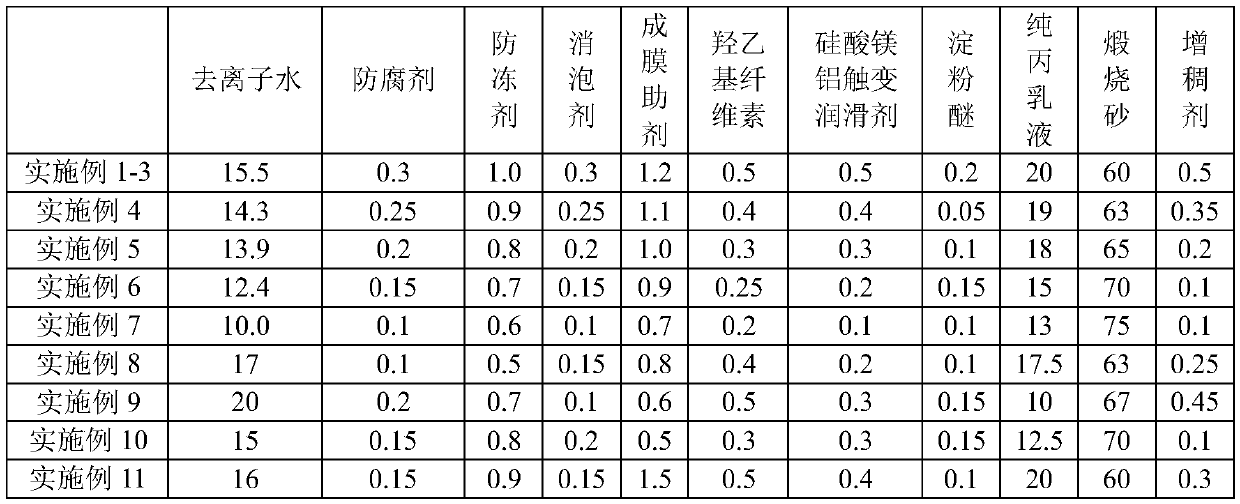

Embodiment 1

[0031] A batch scraping calcined sand real stone paint, which is obtained through the following processing steps:

[0032] According to the data in Table 1, add deionized water into the mixing tank, start the mixer, and at a speed of 500r / min, add preservatives, antifreeze, NXZ defoamers and film-forming aids in sequence, and stir to disperse for 5 minutes , to obtain mixture A after being uniformly dispersed;

[0033] Add hydroxyethyl cellulose, magnesium aluminum silicate thixotropic lubricant and starch ether in sequence to Mixture A at a speed of 500r / min, and stir for 5 minutes; Under high-speed stirring for 60 minutes, after the dispersion is uniform, add pure acrylic emulsion at a speed of 500r / min, and stir for 10 minutes to obtain the mixture B;

[0034] Put the mixture B into the paddle mixer, add the calcined sand under the slow stirring of 300r / min, mix the color evenly, add TT-615 thickener to adjust the viscosity, and then get the batch calcined sand real stone ...

Embodiment 2

[0036] A batch scraping calcined sand real stone paint, which is obtained through the following processing steps:

[0037] According to the data in Table 1, add deionized water into the mixing tank, start the mixer, and at a speed of 650r / min, add preservatives, antifreeze, NXZ defoamers and film-forming aids in sequence, stir and disperse for 5 minutes , to obtain mixture A after being uniformly dispersed;

[0038] Add hydroxyethyl cellulose, magnesium aluminum silicate thixotropic lubricant and starch ether in sequence to Mixture A at a speed of 650r / min, and stir for 5 minutes; at a speed of 1100r / min Stir at high speed to disperse for 60 minutes. After the dispersion is uniform, add pure acrylic emulsion at a speed of 650r / min, and stir for 10 minutes to obtain the mixture B;

[0039] Put the mixture B into the paddle mixer, add the calcined sand under the slow stirring of 400r / min, mix the color evenly, add TT-615 thickener to adjust the viscosity, and then get the batch c...

Embodiment 3

[0041] A batch scraping calcined sand real stone paint, which is obtained through the following processing steps:

[0042] According to the data in Table 1, add deionized water into the mixing tank, start the mixer, and at a speed of 800r / min, add preservative, antifreeze, NXZ defoamer and film-forming aid in sequence, and stir for 5 minutes to disperse , to obtain mixture A after being uniformly dispersed;

[0043] Add hydroxyethyl cellulose, magnesium aluminum silicate thixotropic lubricant and starch ether in sequence to Mixture A at a speed of 800r / min, and stir for 5 minutes; stir at a speed of 1200r / min Stir at high speed to disperse for 60 minutes. After the dispersion is uniform, add pure acrylic emulsion at a speed of 800r / min, and stir for 10 minutes to obtain the mixture B;

[0044] Put the mixture B into the paddle mixer, add the calcined sand under the slow stirring of 500r / min, mix the color evenly, add TT-615 thickener to adjust the viscosity, and then get the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com