A dual-phase organic-inorganic hybrid silica sol and its preparation method and application

A hybrid silica sol and inorganic technology, which is applied in the fields of material synthesis and cultural relics protection, can solve the problems of incomplete polymerization, difficult control of penetration speed, toxicity, etc., and achieve the effects of reducing energy consumption, high weather resistance, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

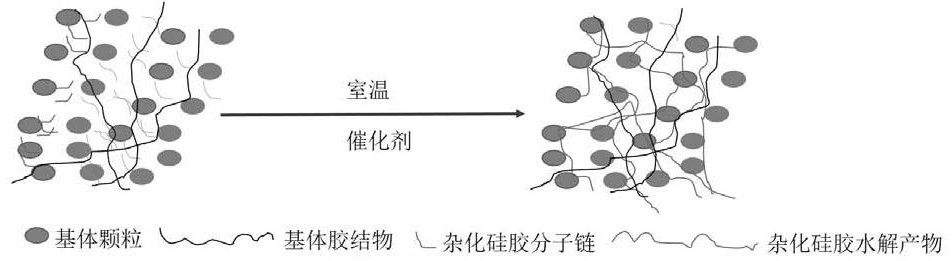

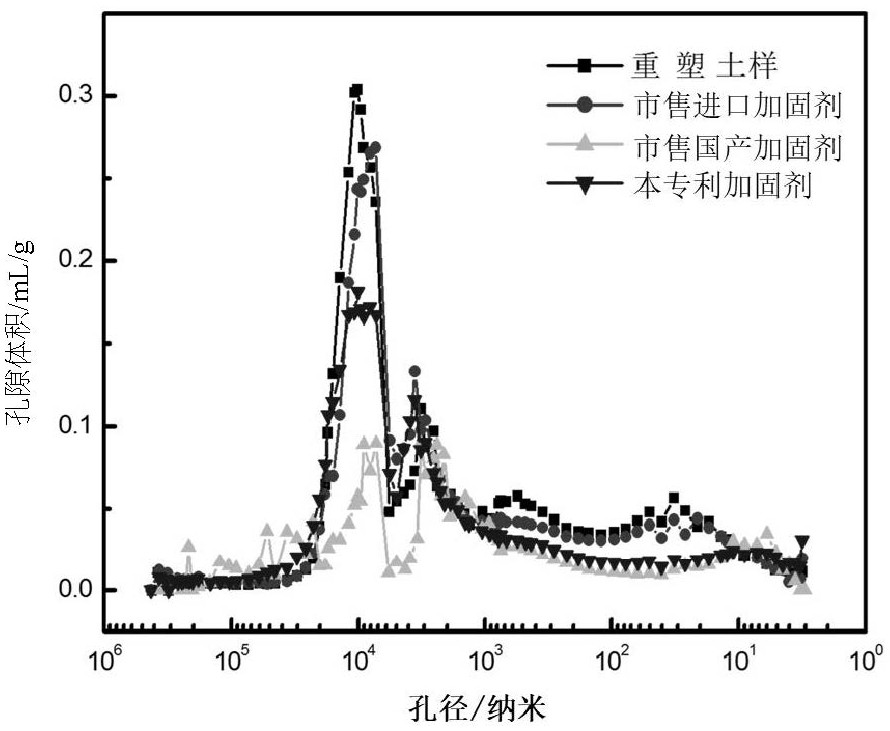

[0056] The present invention starts from the preparation of siloxane, and introduces organic components through hydrolysis and polycondensation of siloxane monomers containing organic functional groups and orthosilicates. The introduction of organic components improves the film-forming properties of traditional silica sols and reduces The brittleness of the film increases the bonding performance, compactness, mechanical properties and corrosion resistance. Compared with the traditional particle-based silica gel without chemical bonds (obtained only by physical mixing), the organic chain introduced by copolymerization has a more uniform composition and achieves mixing at the molecular level, which improves the shortcomings of phase separation of traditional composite materials; The introduction of stable Si-C and C-C bonds under hydrolysis conditions, these stable bonds are part of the bonding matrix, which will improve the reinforcement of organic-inorganic hybrid silica gel ba...

Embodiment 1

[0060] The preparation of a dual-phase organic-inorganic hybrid silica sol and its application in the permanent reinforcement of fragile silicate materials comprises the following steps:

[0061] Add 90 g of 1,2-bis(triethoxysilyl)ethane, 140 g of TEOS and 150 g of absolute ethanol into a three-necked round bottom flask, and stir evenly. Use a constant pressure funnel to add 36g of pure water into the three-necked flask, then add two drops of concentrated hydrochloric acid, transfer the three-necked flask to a constant temperature water bath at 70°C, react for 12h, then keep the temperature at 40°C, and distill under reduced pressure at 15kpa for 30min to remove methanol and part of ethanol to get hybrid silica sol as phase A. Take another three-neck round bottom flask and add 34.17g (KH550), rinse with 30g of absolute ethanol, add 1.50g of deionized water dropwise using a constant pressure funnel, and react at 70°C for 1h as Phase B.

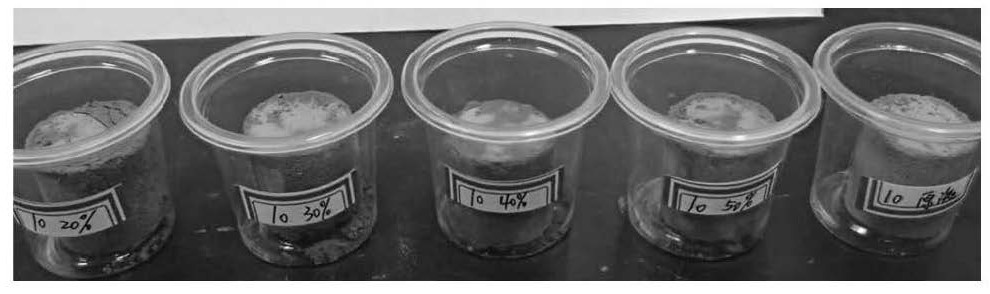

[0062] will m A Phase: m B Phase = 9:...

Embodiment 2

[0064] The preparation of a dual-phase organic-inorganic hybrid silica sol and its application in the permanent reinforcement of fragile silicate materials comprises the following steps:

[0065] Add 90 g of 1,2-bis(triethoxysilyl)ethane, 140 g of TEOS and 150 g of absolute ethanol into a three-necked round bottom flask, and stir evenly. Use a constant pressure funnel to add 36g of pure water into the three-necked flask, then add two drops of concentrated hydrochloric acid, transfer the three-necked flask to a constant temperature water bath at 70°C, react for 12h, then keep the temperature at 40°C, and distill under reduced pressure at 15kpa for 30min to remove methanol and part of ethanol to get hybrid silica sol as phase A. Take another three-neck round bottom flask and add 34.17g (KH550), rinse with 30g of absolute ethanol, add 1.50g of deionized water dropwise using a constant pressure funnel, and react at 70°C for 1h as Phase B.

[0066] Mix the mA phase:mB phase=9:1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com