Numerical control lathe based on deep rotating and distance adjusting of high-speed claw tool for groove planing of gearbox cylinder cover

A technology of CNC lathes and gearboxes, applied in the field of CNC lathes, can solve the problems of reduced driving force, large consumption of lubricating oil, and deviation of the size of the deep groove of the cylinder head, and achieves the same amplitude, eliminates interference factors, and reduces the offset. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

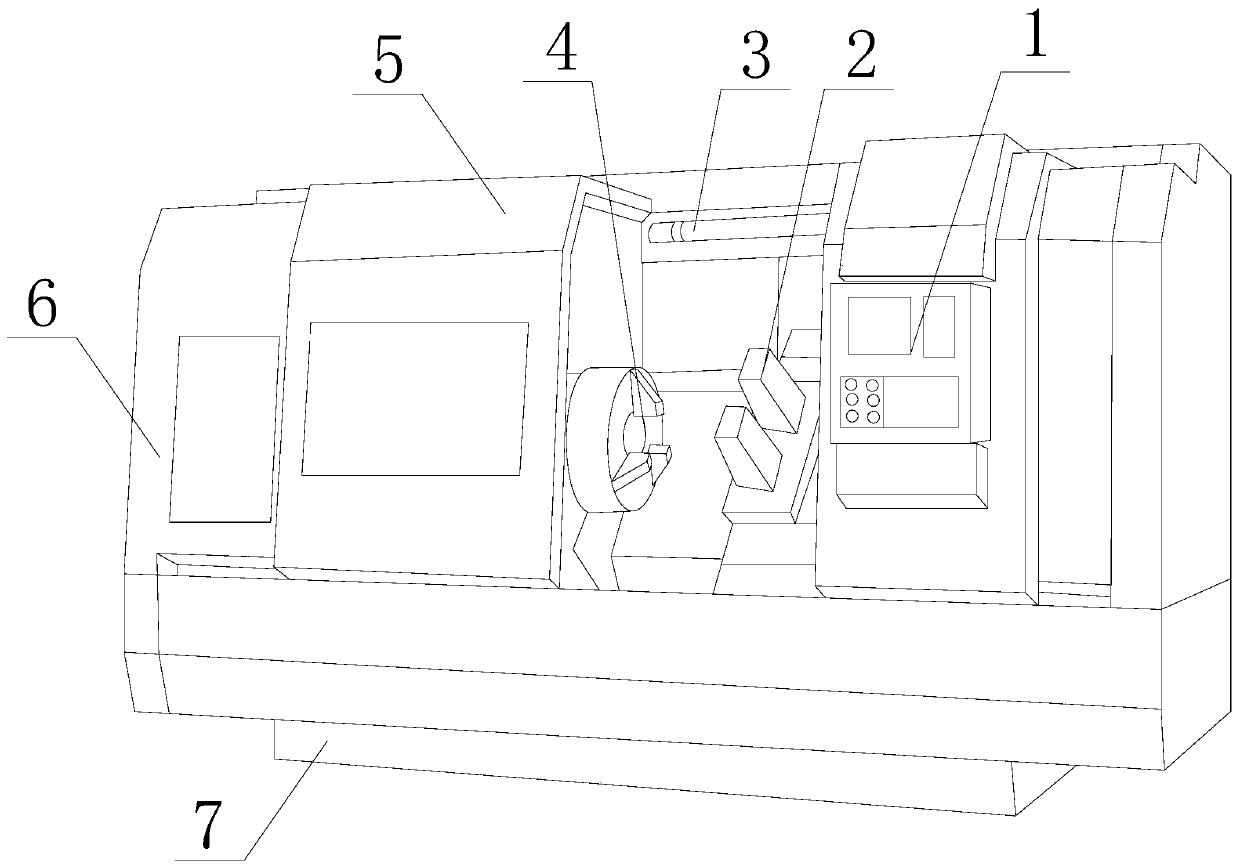

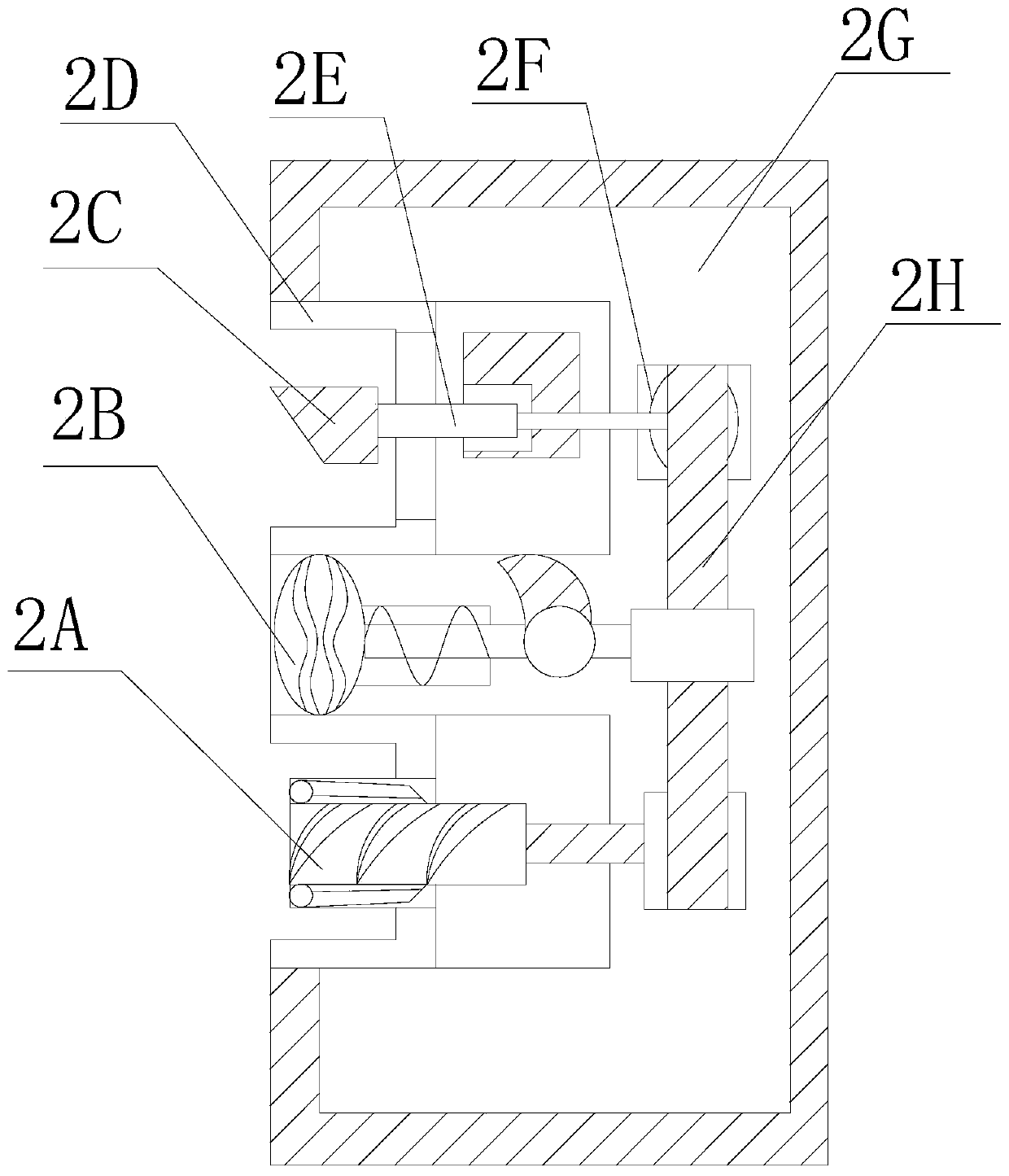

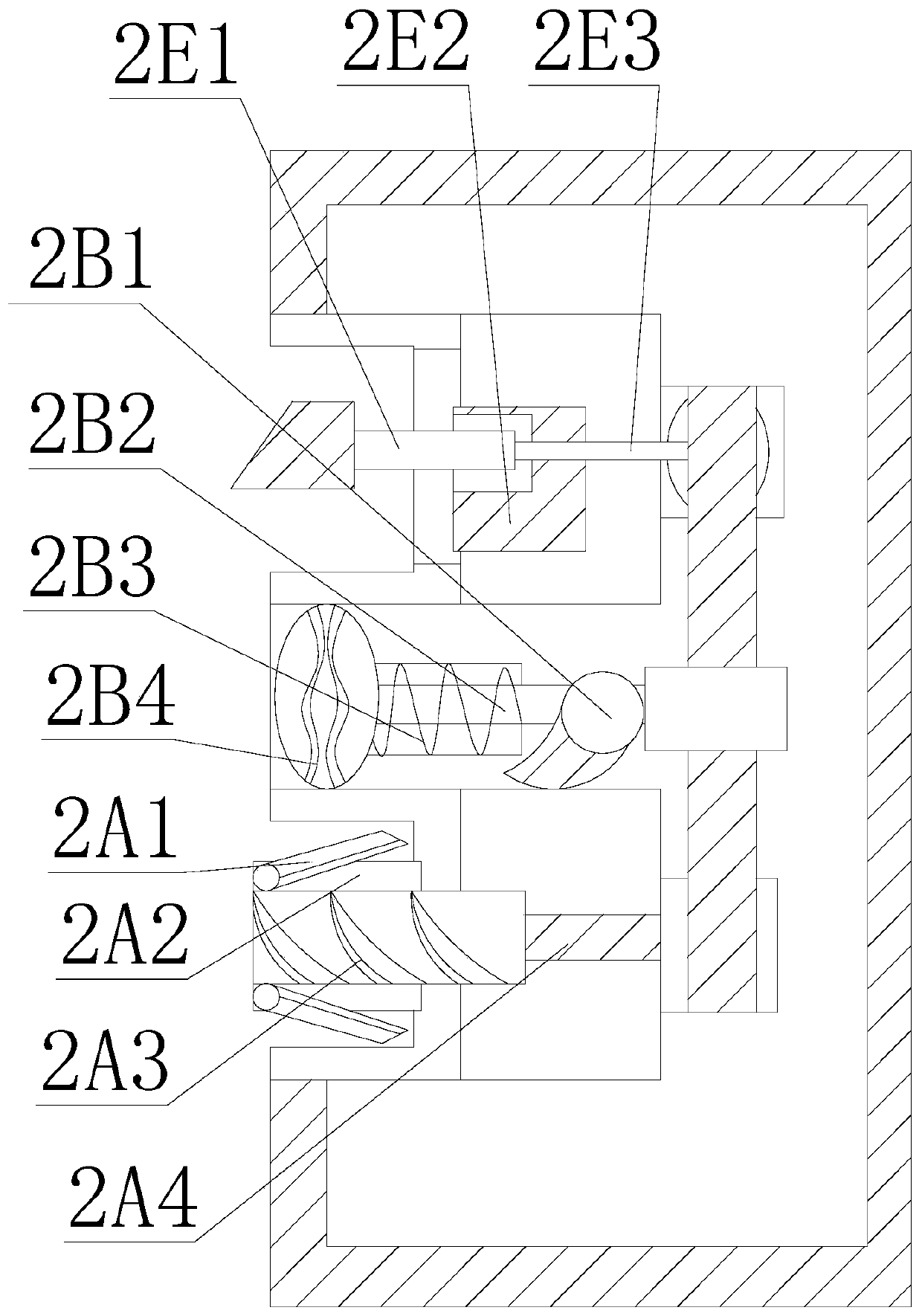

[0032] see Figure 1-Figure 7 , the present invention provides a CNC lathe based on the grooving of the gearbox cylinder head, and the high-speed claw cutter is deep-turning and distance-adjustable. 4. Lathe door 5, mechanical transmission box 6, base plate 7, the two-column end tool holder 2 is installed between the three-jaw chuck 4 and the man-machine interface screen 1, the three-jaw chuck 4 and the The double-column end tool holders 2 are respectively installed at the left and right lower corners of the inner lamp tube 3, the lathe door 5 is mechanically connected with the mechanical transmission box 6, and the bottom surface of the mechanical transmission box 6 is closely attached to the top surface of the base bottom plate 7 , the inner la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com