Preparation method of water purification carbon composite material with low nano zero-valent iron and nano-silver loading capacities

A technology of nano-zero-valent iron and carbon composite materials, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of low removal efficiency of lead ions and cadmium ions, reduce the risk of loss, improve Environmental and economic benefits, efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

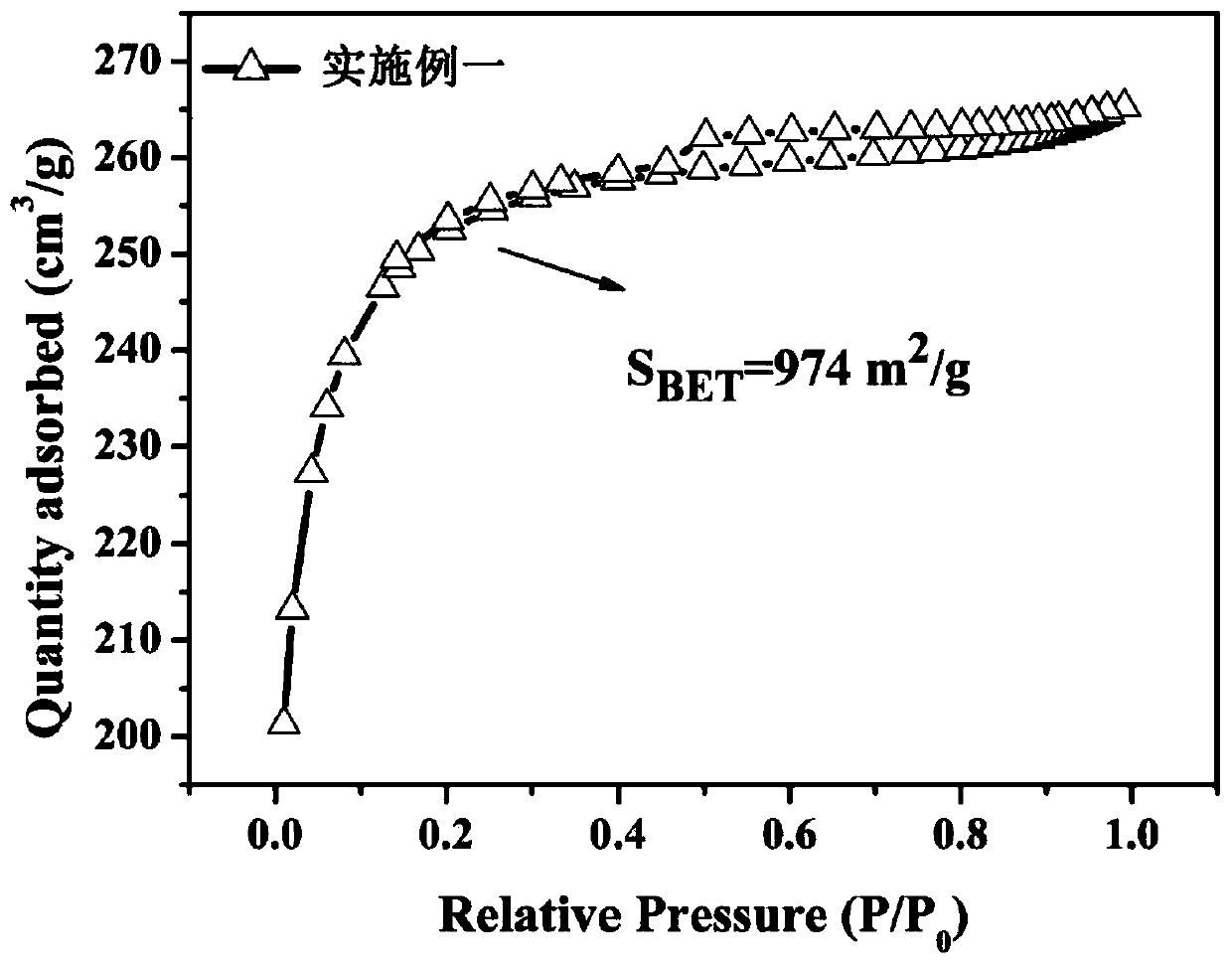

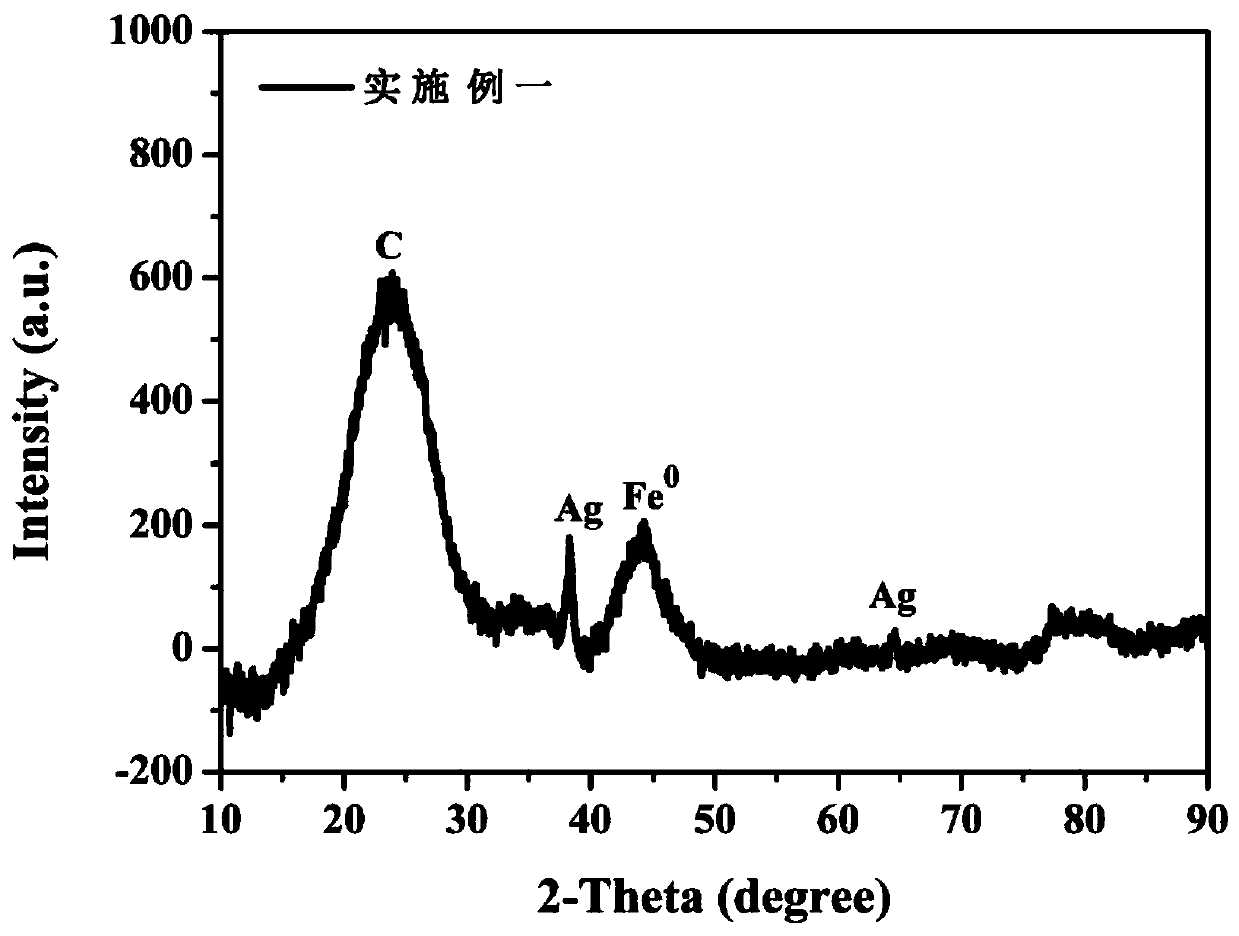

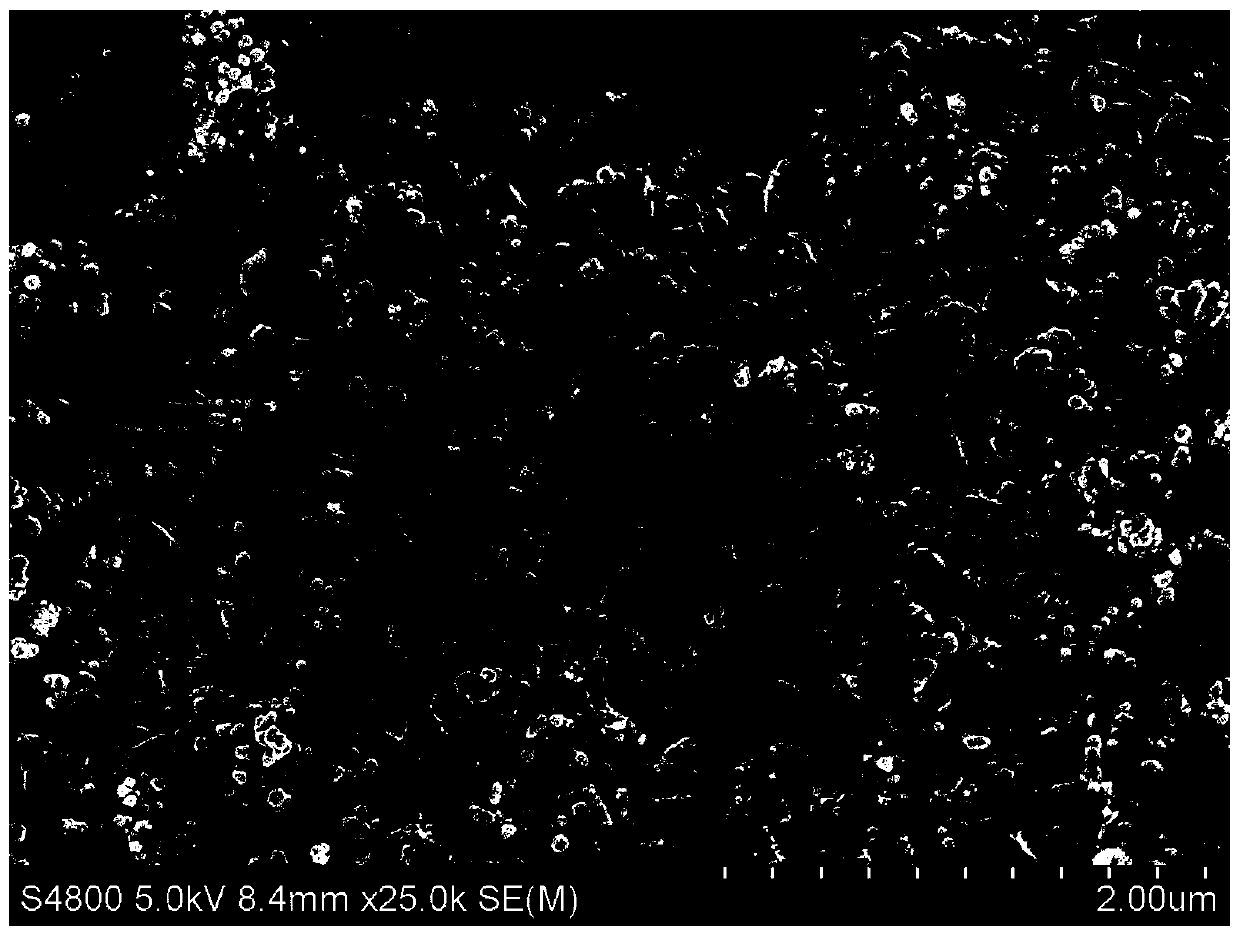

Embodiment 1

[0052] This embodiment provides a method for preparing a water purification carbon composite material with low nanometer zero-valent iron and nanometer silver loading, the method comprising the following steps:

[0053] S1. Screen activated carbon particles with a particle size of 1.0-1.5 mm, clean them with deionized water, and dry them for later use.

[0054] S2. Weigh FeSO according to the mass ratio of iron element to activated carbon as 1:100 4 ·7H 2 O, add 100mL volume ratio of ultrapure water and absolute ethanol mixed solvent of 8:2, and polyethylene glycol-200 of 0.1g, stirrer speed is 400r / min, room temperature, feed N 2 , the reaction time was 120min, and a mixed solution was prepared. Polyethylene glycol-200 as used herein refers to polyethylene glycol with molecular weight not greater than 200.

[0055] S3. Add 20 g of the cleaned activated carbon particles into the mixed solution prepared in step S2 and stir for 120 minutes.

[0056] S4. Add 100mL sodium boro...

Embodiment 2

[0065] This embodiment provides a method for preparing a water purification carbon composite material with low nanometer zero-valent iron and nanometer silver loading, the method comprising the following steps:

[0066] S1. Screen activated carbon particles with a particle size of 1.0-1.5 mm, clean them with deionized water, and dry them for later use.

[0067] S2, according to the mass ratio of iron element and activated carbon as 1:200, take FeSO 4 ·7H 2 O, add 100mL volume ratio of ultrapure water and absolute ethanol mixed solvent of 8:2, and polyethylene glycol-200 of 0.1g, stirrer speed is 400r / min, room temperature, feed N 2 , and the reaction time was 120min to prepare a mixed solution. Polyethylene glycol-200 as used herein refers to polyethylene glycol with molecular weight not greater than 200.

[0068] S3. Add 40 g of the cleaned activated carbon particles into the mixed solution prepared in step S2 and stir for 120 minutes.

[0069] S4. Add 100mL sodium borohy...

Embodiment 3

[0078] This embodiment is a research experiment on the application of low-nano zero-valent iron and nano-silver loading water purification carbon composite materials. This embodiment mainly uses low-concentration Pb in drinking water 2+ and Cd 2+ As the research object, the adsorption performance of the composite material was studied in a constant temperature oscillator by static adsorption test. The experimental condition is C 0 =100ppb, the amount of composite material added is 1.0g / L, the pH value of the solution is 6.0, and the ionic strength is C NaNO3 =0.01M.

[0079] like Figure 10 and Figure 11 As shown, among them, Figure 10 Composite material and former activated carbon that are prepared for embodiment 1 and embodiment 2 are to Pb 2+ The removal efficiency comparison chart, Figure 11 For the composite material and former activated carbon obtained in embodiment 1 and embodiment 2 to Cd 2 + Comparison chart of removal efficiency. From Figure 10 and Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com