A kind of reusable carbon-based nano demulsifier and preparation method thereof

A carbon-based nano-demulsifier technology, which is applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve problems such as complex preparation processes, and achieve simple preparation methods, good demulsification effect, and clear water phase. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

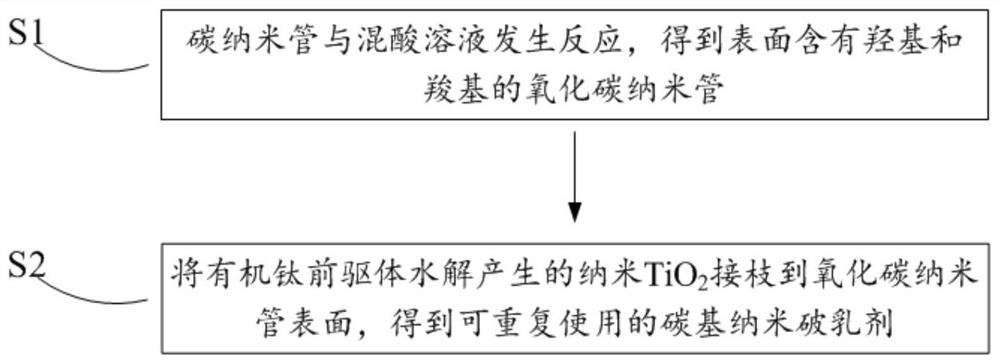

[0018] In a first aspect, the present invention provides a method for preparing a reusable carbon-based nano-demulsifier, such as figure 1 , the preparation method comprises the following steps:

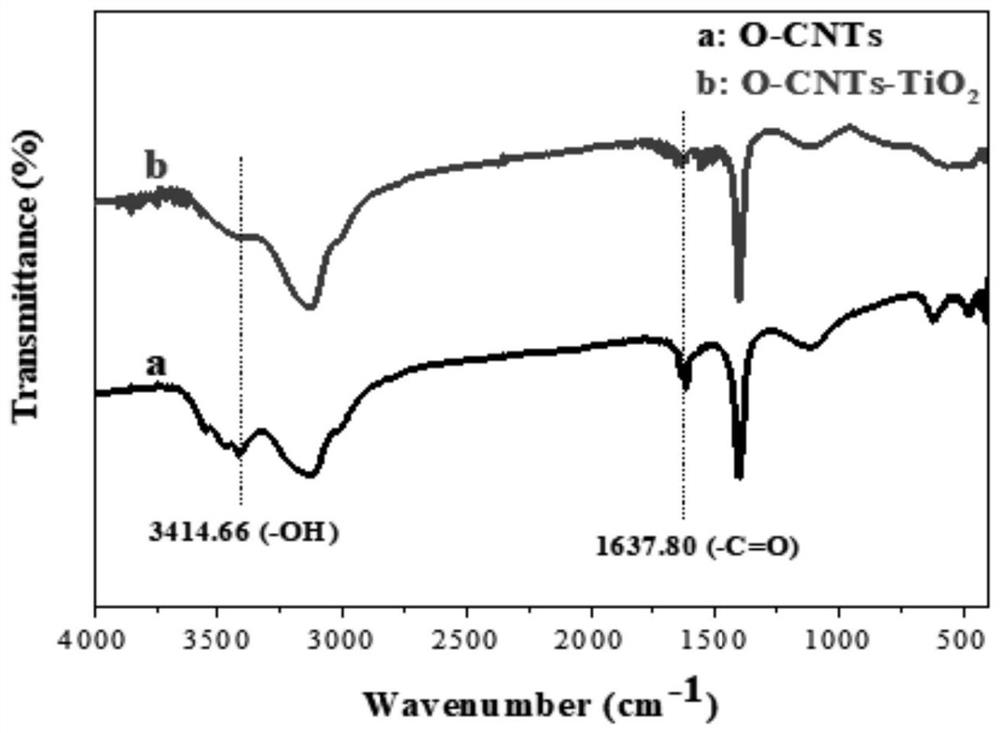

[0019] (1) carbon nanotubes react with mixed acid solution to obtain oxidized carbon nanotubes containing hydroxyl and carboxyl groups on the surface;

[0020] (2) Nano-TiO produced by hydrolysis of organotitanium precursor 2 Grafted onto the surface of oxidized carbon nanotubes to obtain a reusable carbon-based nanodemulsifier.

[0021] According to the present invention, the carbon nanotube described in step (1) reacts with the mixed acid solution to obtain the oxidized carbon nanotube containing hydroxyl and carboxyl on the surface, comprising the following steps:

[0022] (a) uniformly mixing nitric acid and sulfuric acid to obtain a mixed acid solution;

[0023] (b) adding carbon nanotubes to the above-mentioned mixed acid solution, and stirring to obtain a suspension;

[00...

Embodiment 1

[0066] This embodiment provides a reusable carbon-based nano demulsifier, which is obtained through the following steps:

[0067] Mix 100 parts by weight of concentrated nitric acid and 33 parts by weight of concentrated sulfuric acid to obtain a mixed acid solution; then add 1 part by weight of carbon nanotubes to the above mixed acid solution, and stir at a temperature of 80°C for 12 hours to obtain a suspension ; The above-mentioned suspension is centrifuged at a speed of 4100rpm, and repeatedly washed with deionized water until it is neutral to obtain a black product; finally, the obtained black product is vacuum freeze-dried to obtain carbon oxide nanotubes containing hydroxyl and carboxyl groups on the surface , wherein the vacuum freeze-drying temperature is -40°C, and the vacuum freeze-drying time is 36h.

[0068] 25 parts by weight of isopropyl titanate were dissolved in 200 parts by weight of absolute ethanol, and mixed solution I was obtained after stirring for 1 h,...

Embodiment 2

[0071] This embodiment provides a reusable carbon-based nano demulsifier, which is obtained through the following steps:

[0072] Mix 100 parts by weight of concentrated nitric acid and 33 parts by weight of concentrated sulfuric acid to obtain a mixed acid solution; then add 0.75 parts by weight of carbon nanotubes to the above mixed acid solution, and stir at a temperature of 70°C for 24 hours to obtain a suspension centrifuge the above suspension at a speed of 5000rpm, and repeatedly wash with deionized water until it is neutral to obtain a black product; finally carry out vacuum freeze-drying of the obtained black product to obtain oxidized carbon nanotubes containing hydroxyl and carboxyl groups on the surface , wherein the vacuum freeze-drying temperature is -30°C, and the vacuum freeze-drying time is 48h.

[0073] Dissolve 20 parts by weight of tetraisobutyl titanate in 200 parts by weight of isopropanol, and stir for 0.5 h to obtain mixed solution I, wherein the stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com