Preparation method of royal jelly acid microcapsules

A technology of royal jelly acid and microcapsules, which is applied in the field of preparation of royal jelly acid microcapsules, can solve the problems of certification, large particle size of royal jelly acid, and failure to provide it, and achieve the effects of convenient transportation, reducing irritation, and improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

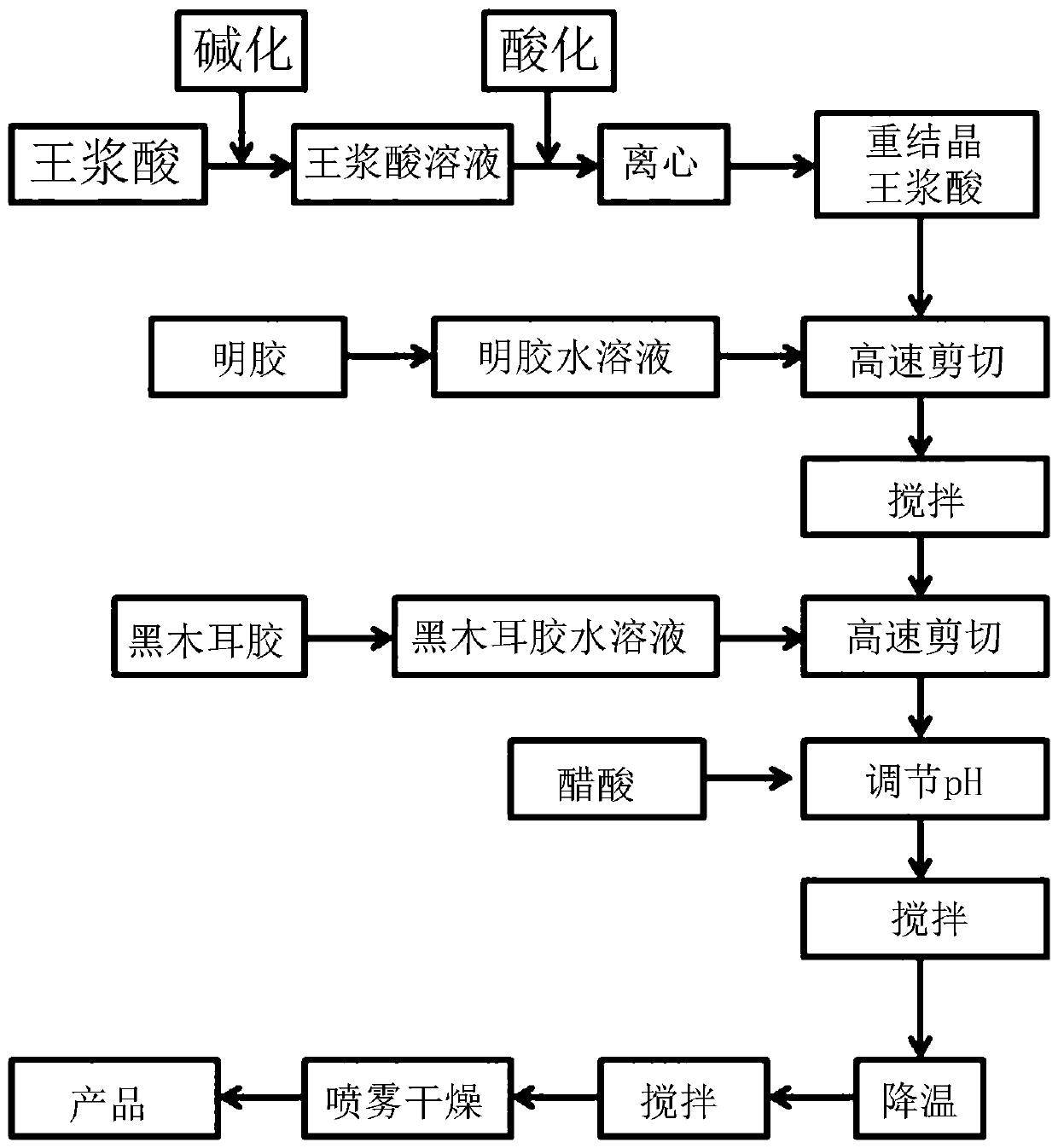

Method used

Image

Examples

Embodiment 1

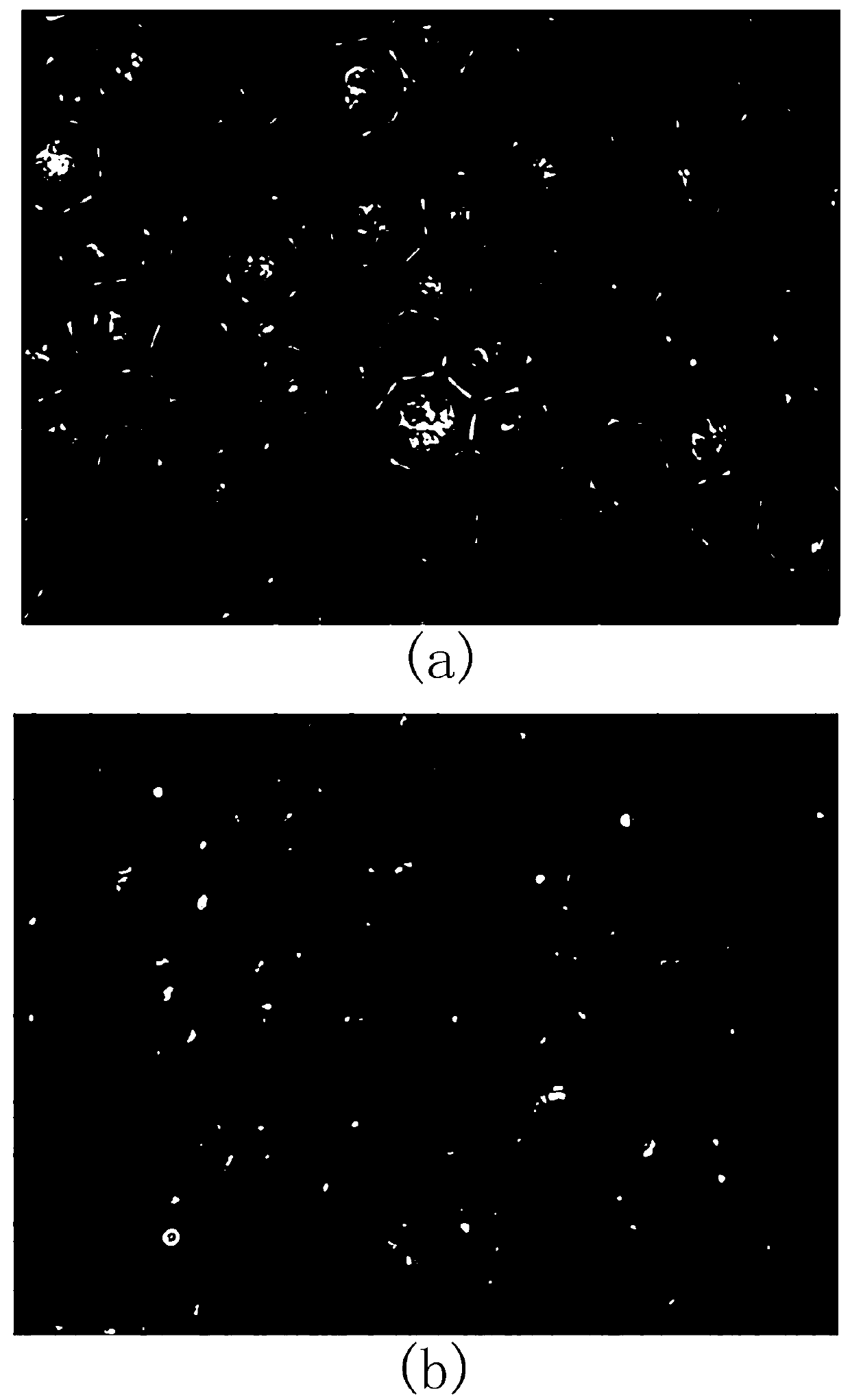

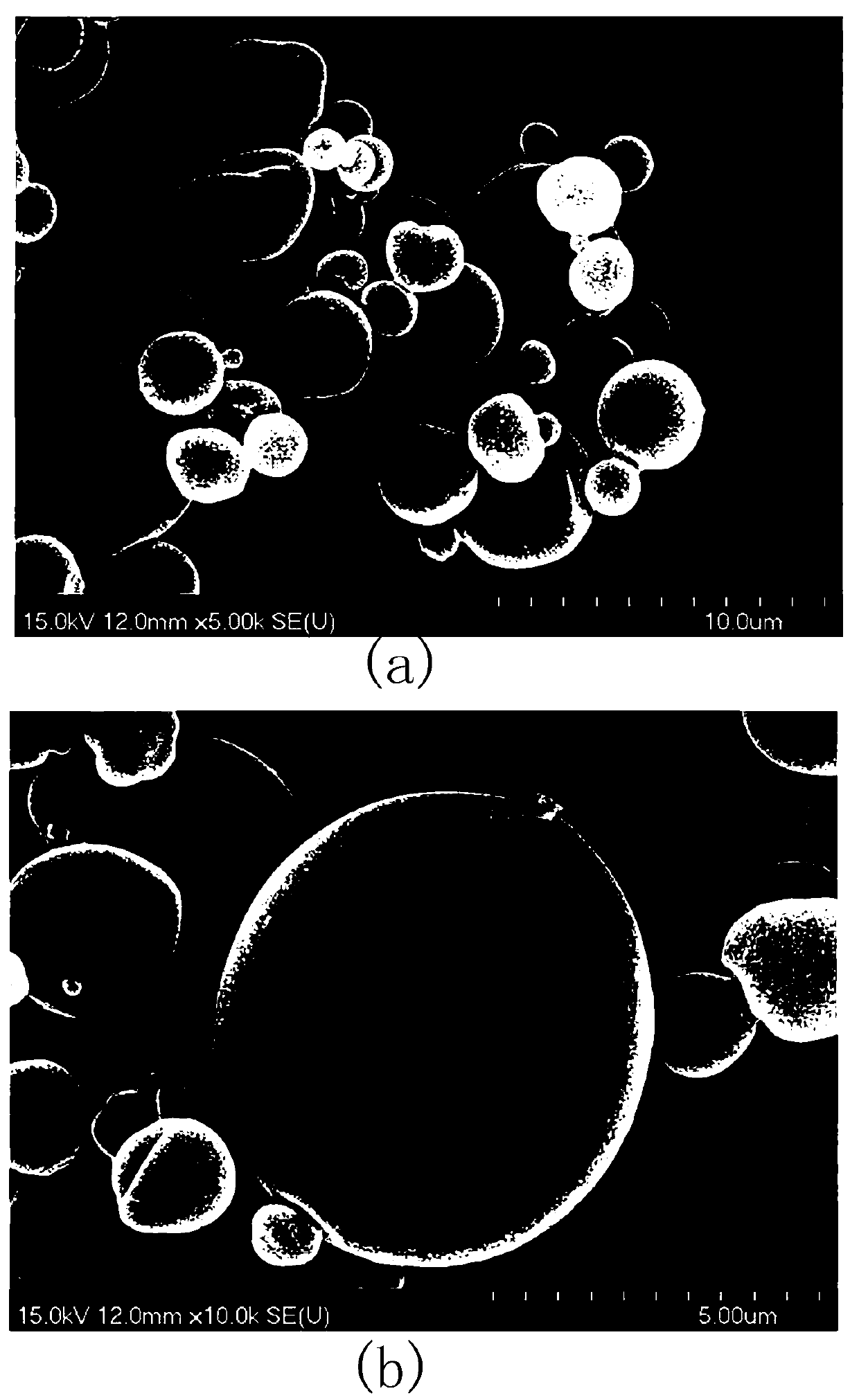

[0051] Dissolve 1.0013 g of gum arabic and 1.0034 g of gelatin in 50 mL of deionized water respectively, and dissolve them completely in a water bath at 40°C. Dissolve 1.0831g of royal jelly slag and 0.2752g of NaOH in 50mL of deionized water, ultrasonicate for 3 minutes to completely dissolve the royal jelly acid, then adjust the pH to 4.80 with hydrochloric acid, take a small amount of turbid solution and observe it under a microscope. Centrifuge at 2000 x g, 5 min, 20°C (room temperature), and collect the pellet. The precipitation was dispersed with black fungus gum solution, sheared at 12000 rpm for 3 min, and then magnetically stirred at a speed of 800 rpm for 15 min in a water bath at 40°C. The gelatin solution was poured, sheared at 12000 rpm for 3 min, adjusted to pH 4.0 with 10% acetic acid, and then magnetically stirred at a speed of 800 rpm for 20 min in a water bath at 40°C. The system was rapidly cooled to 10 °C, and magnetically stirred at a speed of 300 rpm for...

Embodiment 2

[0054] Dissolve 1.0321 g of black fungus gum and 1.0216 g of gelatin in 50 mL of deionized water respectively, and dissolve them completely in a water bath at 40°C. Dissolve 1.1036g of royal jelly slag and 0.3049g of NaOH in 50mL of deionized water, ultrasonicate for 3 minutes to completely dissolve the royal jelly acid, then adjust the pH to 4.80 with hydrochloric acid, take a small amount of turbid solution and observe it under a microscope. Centrifuge at 2000 x g, 5 min, 20°C (room temperature), and collect the pellet. The precipitation was dispersed with black fungus gum solution, sheared at 12000 rpm for 3 min, and then magnetically stirred at a speed of 800 rpm for 15 min in a water bath at 40°C. The gelatin solution was poured, sheared at 12000 rpm for 3 min, adjusted to pH 4.0 with 10% acetic acid, and then magnetically stirred at a speed of 800 rpm for 20 min in a water bath at 40°C. The system was rapidly cooled to 10 °C, and magnetically stirred at a speed of 300 r...

Embodiment 3

[0058] 4.0025g of silver glue and 4.0067g of gelatin were weighed and completely dissolved in 200mL of deionized water in a water bath at 40°C. Add 4.8086g of royal jelly slag to 100mL of deionized water, add 1.0012g of NaOH, stir properly and sonicate for 3min to completely dissolve the slag, then adjust the pH to 4.70 with 10% hydrochloric acid, quickly transfer it to a centrifuge tube, at 3000x g, Centrifuge at 19°C (room temperature) for 5 min. After discarding the supernatant, rinse the centrifuge tube with gelatin solution to transfer the pellet out. The gelatin containing recrystallized royal jelly acid was sheared at a shear rate of 10,000 rpm for 3 min, and then placed in a 40° C. water bath with magnetic stirring at a speed of 800 rpm for 15 min. The silver solution was poured at a constant speed under high shear at 10,000 rpm for a total of 3 min of shearing time, pH was adjusted to 4.0 with 10% acetic acid, and then magnetically stirred at a speed of 800 rpm for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com